Six-degree-of-freedom large-stroke uncoupled large hollow series-parallel piezoelectric micro-motion platform

A technology of large hollow series and micro-moving platform, which is applied to piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc. The problem of bulkiness and other problems is achieved, and the overall structure is simple and compact, the working surface is large, and the effect of expanding the displacement stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

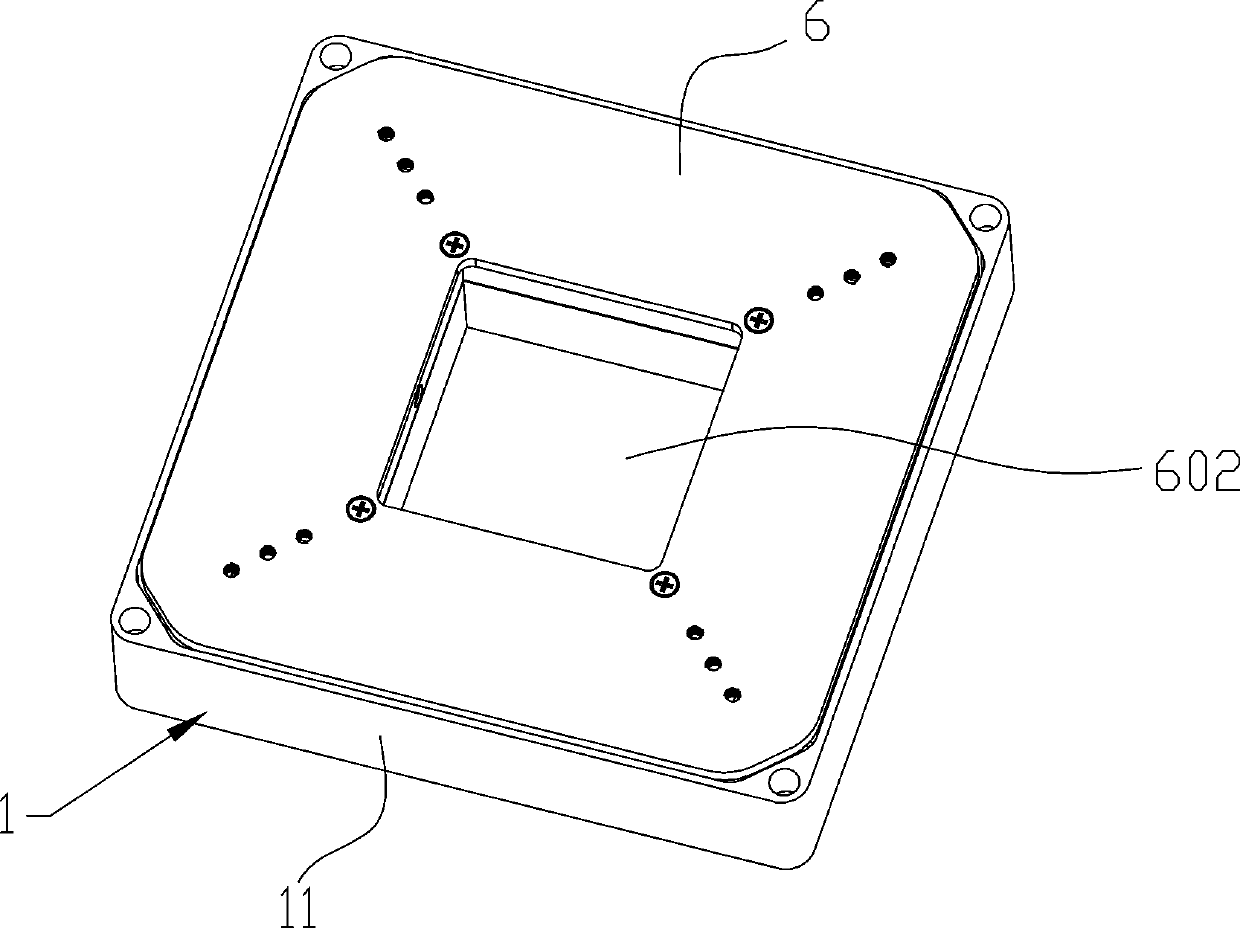

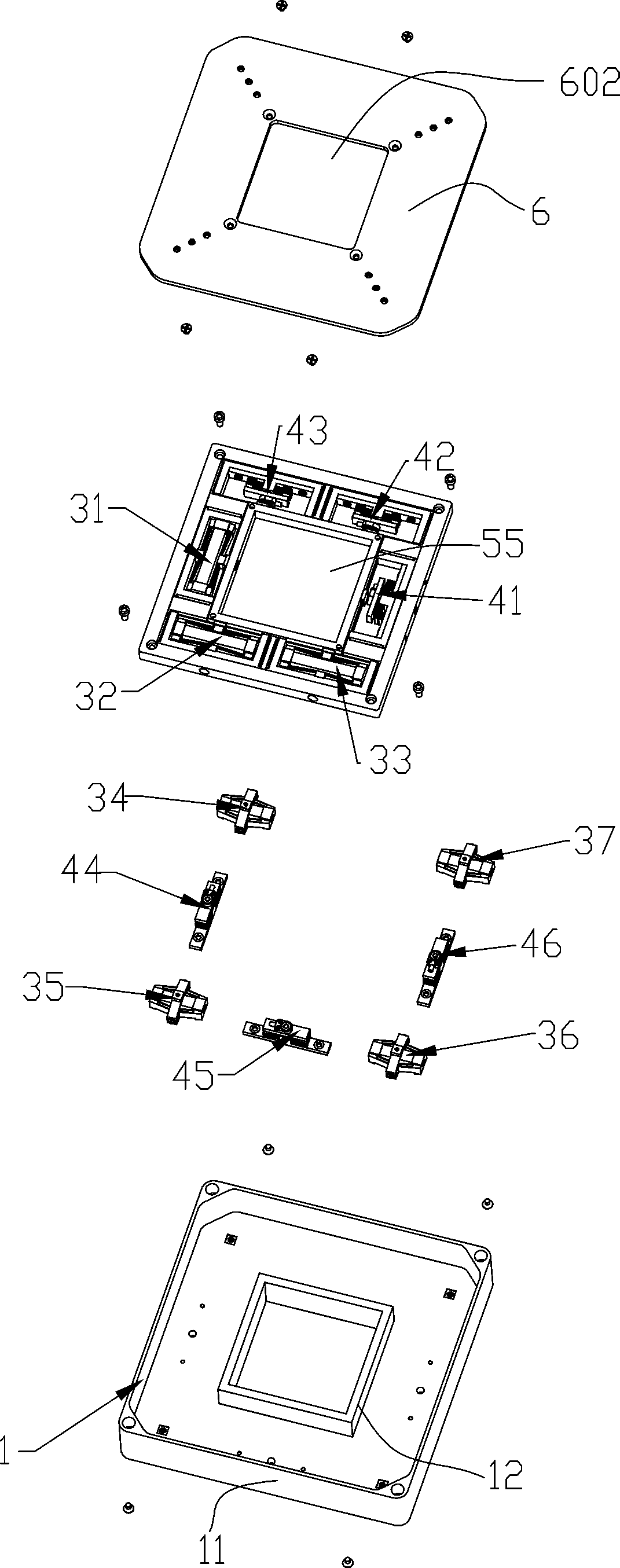

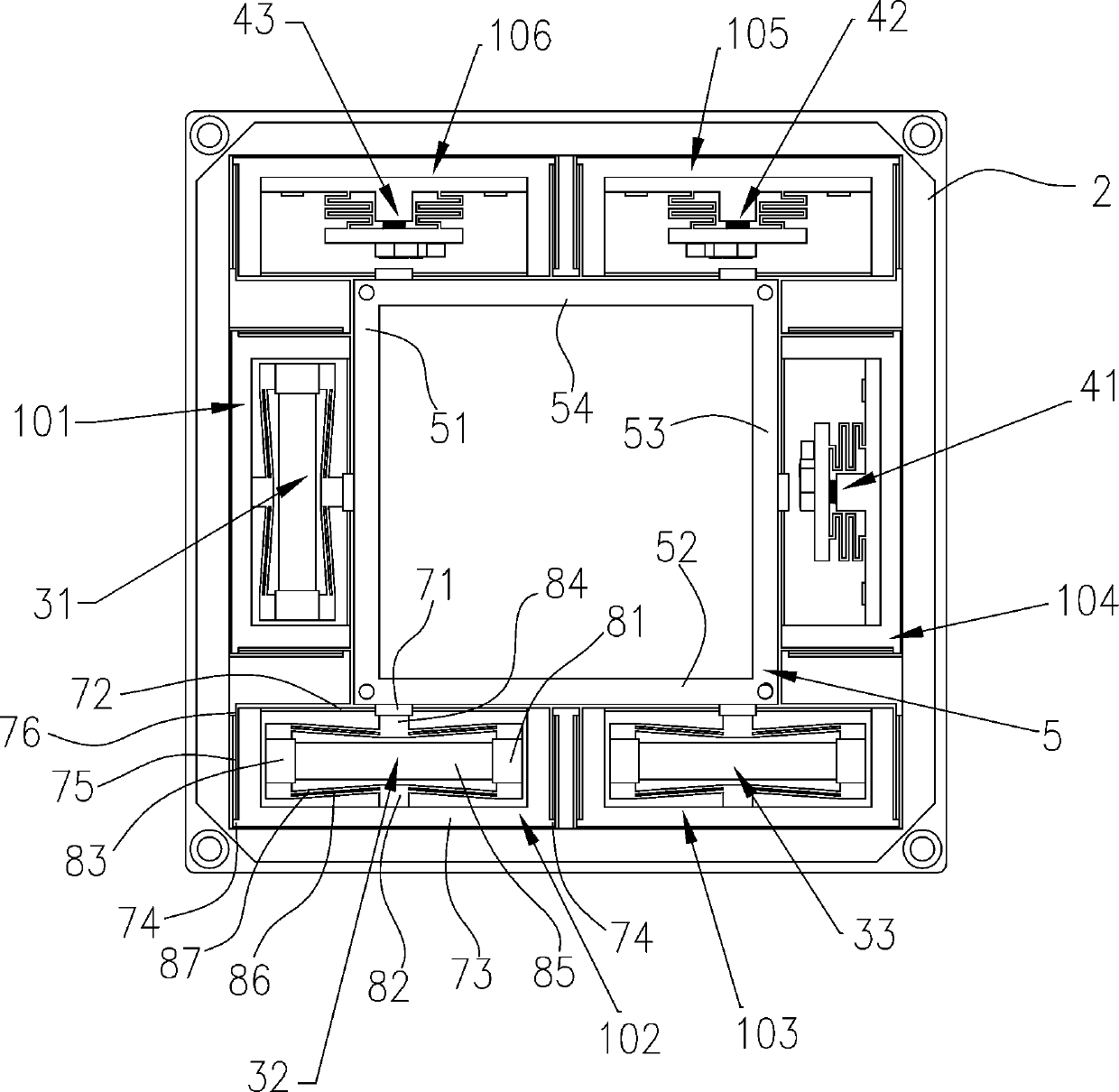

[0053] Figure 1 to Figure 17 It is a structural schematic diagram of the present invention, wherein the reference numerals are: base 1, first guide unit 101, second guide unit 102, third guide unit 103, fourth guide unit 104, fifth guide unit 105, sixth guide unit Unit 106, enclosure 11, tubular body 12, second platform 2, first storage tank 21, second storage tank 22, first drive unit 31, second drive unit 32, third drive unit 33, fourth drive unit 34. The fifth drive unit 35, the sixth drive unit 36, the seventh drive unit 37, the first sensor component 41, the second sensor component 42, the third sensor component 43, the fourth sensor component 44, the fifth sensor component 45, The sixth sensor assembly 46, the first platform 5, the first edge 51, the second edge 52, the third edge 53, the fourth edge 54, the second hollow hole 55, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com