Dry type ironing structure

A drying and ironing hood technology, applied in washing devices, hand irons, textiles and papermaking, etc., can solve problems such as loss of clothing processing enterprises, moldy and deteriorating clothing, etc., and achieve the effect of saving steam generating devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

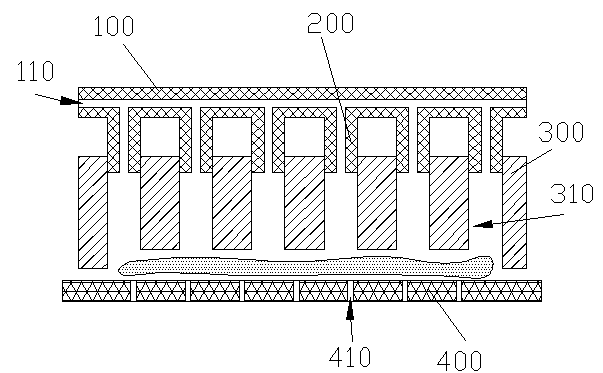

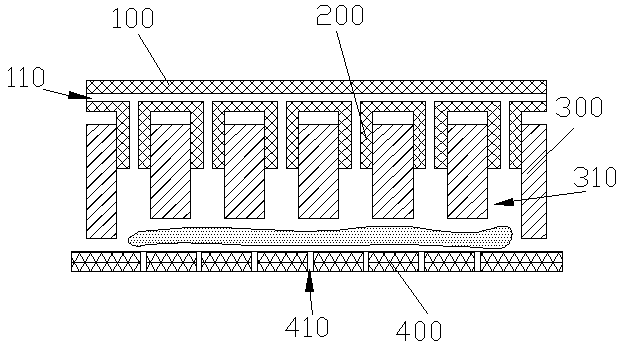

[0020] refer to figure 1 , in this embodiment, the dry ironing structure includes an ironing table 400 for placing textiles and an ironing cover 300 for covering the textiles, the ironing cover 300 is provided with an air compression device, and the ironing cover 300 There is also an ultrasonic atomization device evenly distributed inside, the ironing table 400 or the ironing cover 400 is provided with a valve body 410, and the ultrasonic atomization device makes the ironing table 400 and the ironing cover 400 The space in the space is filled with air containing water mist, the air containing water mist is compressed by the air compression device, the temperature of the compressed air rises and the water mist is heated into steam, and the steam irons the clothes. After the ironing is completed, open the Valve body 410 steam discharge.

[0021] In the above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com