Mounting method of bottom width overhaul hanging basket of bridge

An installation method and bridge technology, which are applied in bridges, bridge parts, bridge construction, etc., can solve the problems of unsuitable bridge maintenance suspension basket structure, etc., and achieve the effect of convenient installation and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

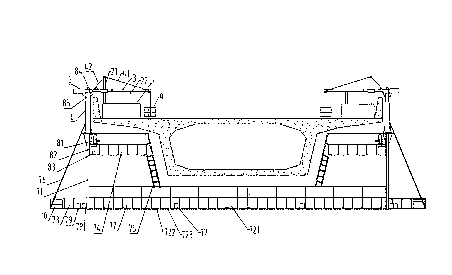

[0023] like figure 1 As shown, a method for installing a suspension basket for overhauling the bottom width of a bridge in this embodiment includes the following steps:

[0024] a, the parts of running gear 1 and round steel track 19 are transported to the bridge by transport vehicle.

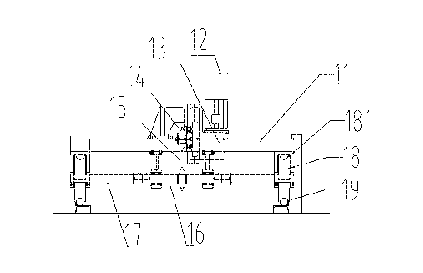

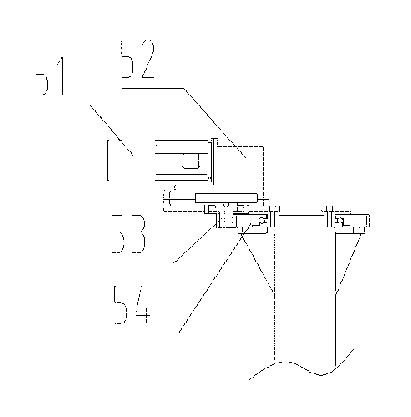

[0025] b. The components of the running gear 1 and the round steel track 19 are assembled on the bridge, and the round steel track 19 is laid on both sides of the bridge deck. The running gear 1 includes symmetrically arranged first running gears with the same structure 1 and the second traveling mechanism 1, the first traveling mechanism 1 and the second traveling mechanism 1 comprise a mounting plate 11, the bottom of the mounting plate 11 is provided with a roller 18 driven by the first motor 12, and the roller 18 is installed on a round steel track 19 Above, the mounting plate 11 is provided with a column, wherein, the column is provided with a horizontal telescoping pole 3, one end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com