Labyrinth seal, cleaning unit and method, and solution film-forming method

A technology of labyrinth sealing and cleaning objects, applied in the field of cleaning units and labyrinth seals, can solve the problems of dry ice leakage, adhesion, weak attraction, etc., to prevent the external size from increasing, inhibit the external size from increasing, and achieve high sealing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

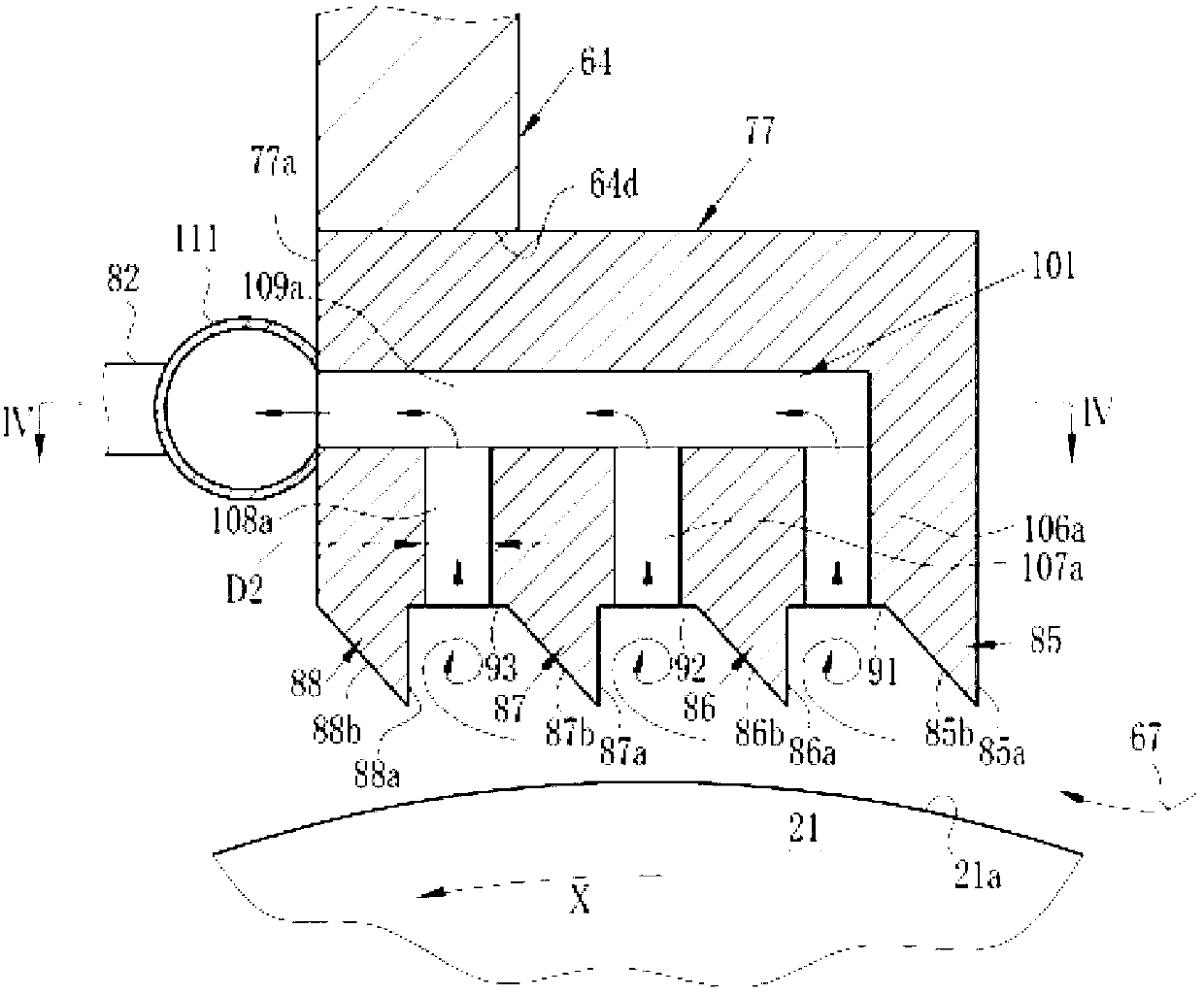

[0097] The thin film 41 is produced by the solution film forming apparatus 10 . The respective diameters D2 of the second passages 106a to 106d, 107a to 107d, and 108a to 108d of the labyrinth seal 77 are equal to each other, and are shown in the "D2" column of Table 1 (unit: mm). In addition, the pitch L1 of the second passing paths 108a to 108d of the groove 93, the pitch L1 of the second passing paths 107a to 107d of the groove 92, and the pitch L1 of the second passing paths 106a to 106d of the groove 91 are equal to each other, as shown in Table 1. "L1" column (unit: mm). In addition, the column of "Number of Second Passages" in Table 1 describes the number of second passages branched from one first passage. For example, three second passages 106a, 107a, and 108a are formed by branching from the first passage 109a, so it is "3". Since the 1st passing path 109a, the 1st passing path 109b, the 1st passing path 109c, and the 1st passing path 109d have the same structure, i...

Embodiment 2

[0102] A labyrinth formula is used in which the distance L1 of the second passages 108a to 108d, the distance L1 of the second passages 107a to 107d, and the distance L1 of the second passages 106a to 106d are the values shown in the "L1" column of Table 1. Seals 76,77. And the tube 82 connected to each manifold 111 is set as one. Conditions other than these were the same as in Example 1.

[0103] In the same manner as in Example 1, it was evaluated whether contamination, solidified dry ice, or the like leaked to the outside from between the labyrinth seals 76, 77 and the peripheral surface 21a. The evaluation results are shown in Table 1.

Embodiment 3

[0105] A labyrinth formula is used in which the distance L1 of the second passages 108a to 108d, the distance L1 of the second passages 107a to 107d, and the distance L1 of the second passages 106a to 106d are the values shown in the "L1" column of Table 1. Seals 76,77. And the tube 82 connected to each manifold 111 is set as one. Conditions other than these were the same as in Example 1.

[0106]In the same manner as in Example 1, it was evaluated whether contamination, solidified dry ice, or the like leaked to the outside from between the labyrinth seals 76, 77 and the peripheral surface 21a. The evaluation results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com