Combined range hood structure

A range hood and combined technology, applied in the field of kitchen utensils, can solve the problems of complex structure, inability to discharge oil fume, inconvenient installation, disassembly and repair, etc., and achieve the effect of simple and stable structure and easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

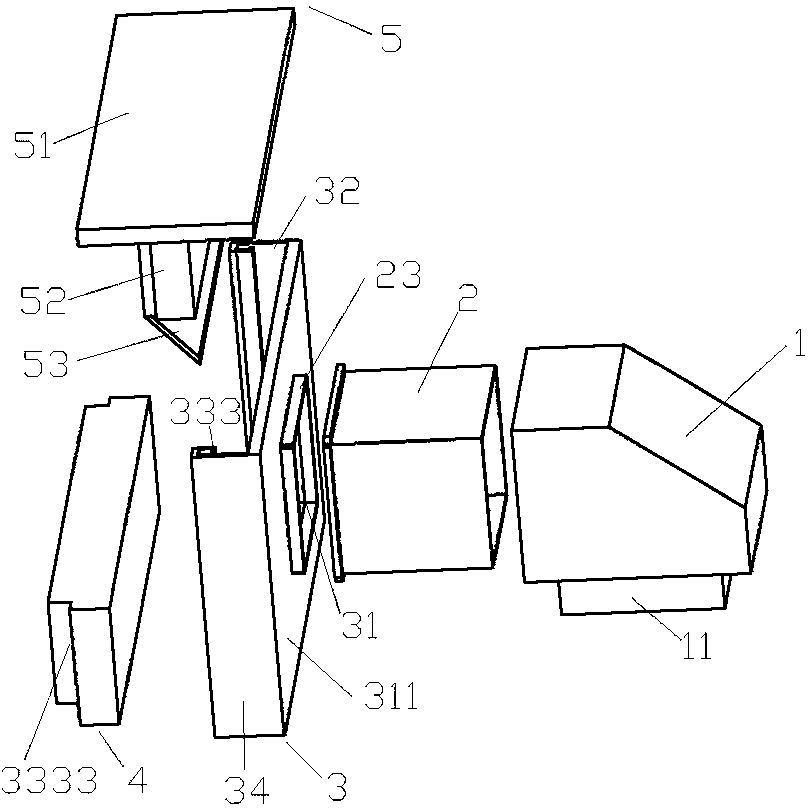

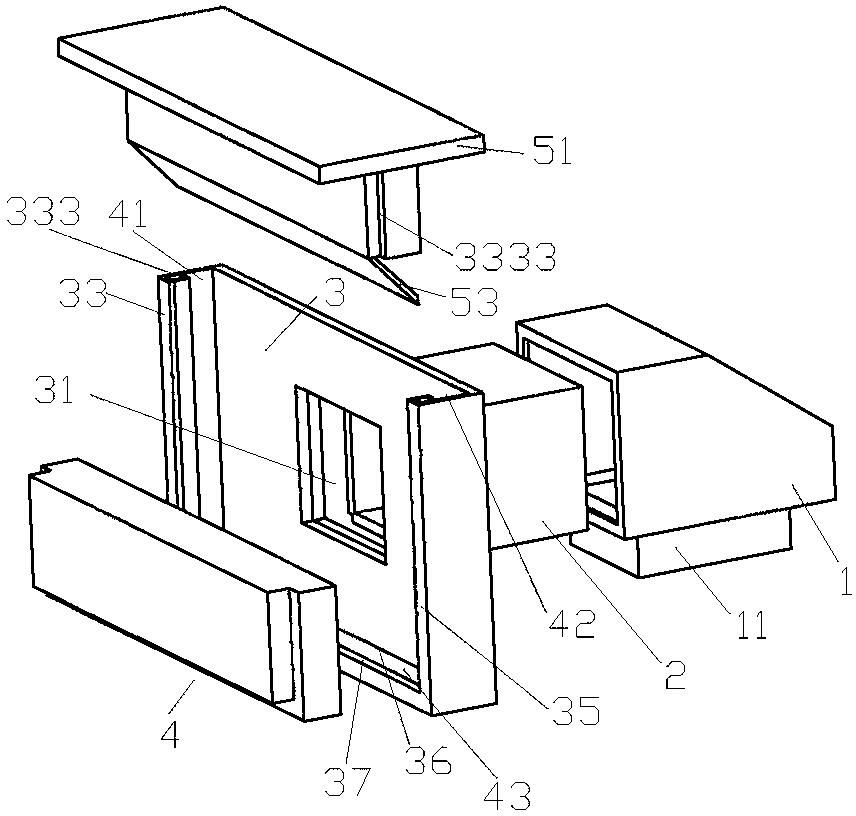

[0017] Example 1, such as figure 1 , 2 As shown, a combined range hood structure includes an oil fume exhaust hood 1, an oil fume exhaust channel 2 and a support frame. The support frame includes a fixing plate 3, a lower socket plate 4 and an upper socket plate 5. The oil exhaust hood 1 has a Inlet and outlet, the outlet of the oil fume hood 1 is connected with one end of the oil fume passage 2, and the other end of the oil fume passage 2 is connected with the opening 31 arranged on the fixing plate 3, and the fixing plate 3 includes a piece with the opening 31 The main board 311 extends along the left and right sides and the lower side of the main board 311 toward the side away from the oil fume exhaust channel 2 to form a left side board 32, a left side board 33, a right side board 34, a right side board 35, a lower side board 36 and a lower side board. Baffle plate 37, left side plate 32 and left baffle plate 33, right side plate 34 and right baffle plate 35, lower si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com