EPS (expandable polystyrene) helmet and manufacturing process thereof

A technology of protective caps and cap covers, applied in the field of protective caps, which can solve the problems of stuffy head, heavy head, and those who love beauty are unwilling to wear it, and achieve the effect of cool head and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

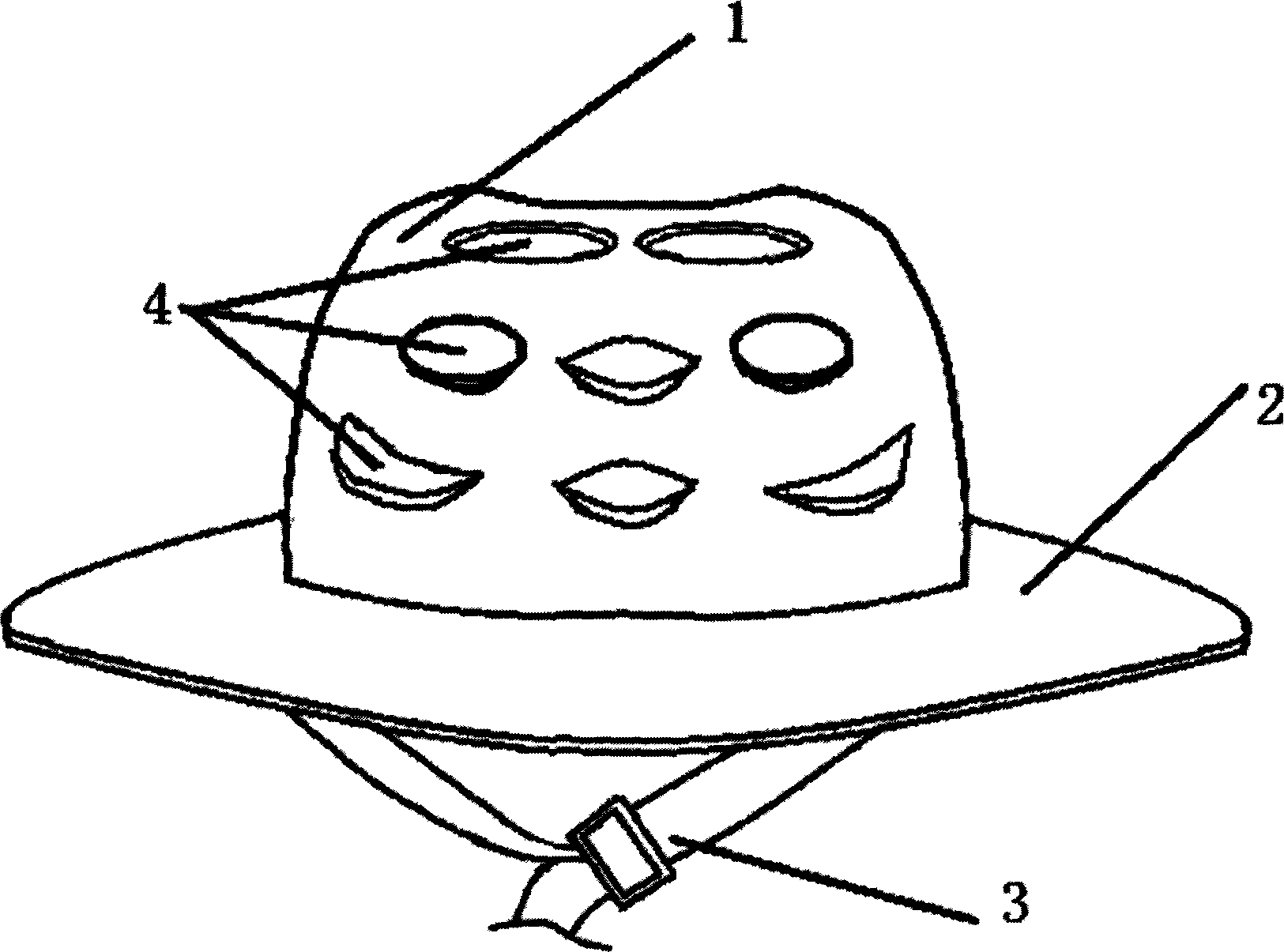

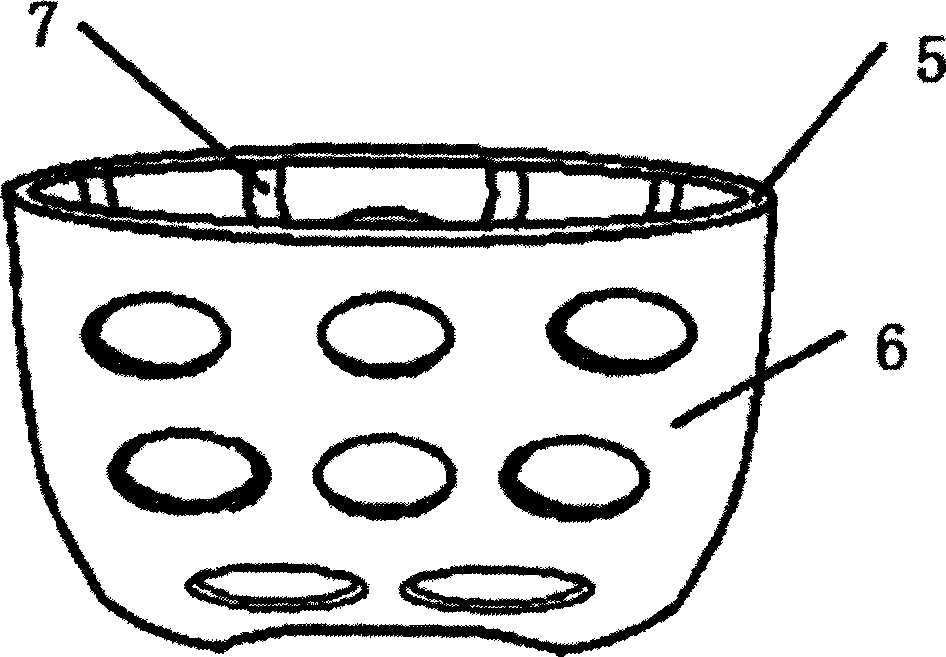

[0022] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 , figure 2 :

[0023] The EPS protective cap is composed of EPS substrate material, glue material, and outer layer molding material. The outer layer molding material is composed of cap head 1 and visor 2. The inner diameter of the outer layer molding material and the hat cover made of EPS substrate material The outer diameter of 5 is matched, and the cap cover 5 and cap head 1 made of EPS substrate material are bonded together by glue material, and the cap cover 5 and cap head 1 made of EPS substrate material have through air holes 4.

[0024] EPS substrate material thickness is 10mm;

[0025] The outer modeling material is made of cloth material;

[0026] There are 8 evenly distributed strip-shaped non-woven raised strips 7 in the cap cover.

[0027] Its production process is as follows:

[0028] (1) First make the EPS substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com