Improved polymerization reactor

A polymerization reactor, import and export technology, applied in polymerization reaction. , In the field of polymerization reactors, it can solve the problems of increased acetaldehyde content of impurities, increased impurities, and consumption of cooling water, etc., and achieve the effects of improved catalyst activity, increased production capacity, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

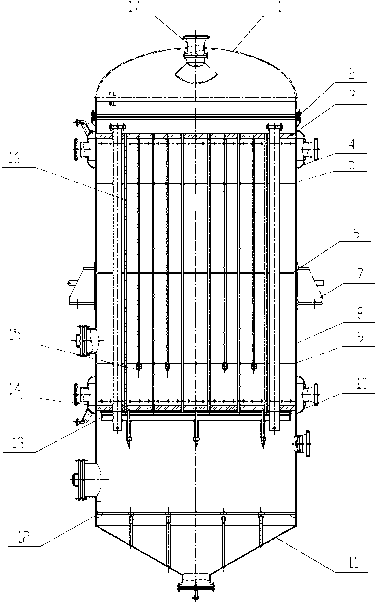

[0015] Example: The polymerization reactor in this embodiment is in the form of a shell-side cylinder and a tube-side heat exchange tube, as shown in the attached figure 1 As shown, the main structure includes an upper head 1, a shell-side cylinder 8, a conical head 11, an upper tube sheet 3, a lower tube sheet 14, and a heat exchange tube 15. The main improvement is that a The upper annular flow channel 4 and the lower annular flow channel 10, and small holes of different diameters are opened in the corresponding positions of the shell-side cylinder 8; three baffle support plates are arranged in the shell-side cylinder 8 along the direction of the heat exchange tubes, and the middle baffle A hole of φ250mm is set in the middle of the support plate 6, and 120 small holes of φ10mm are respectively arranged on the upper baffle support plate 5 and the lower baffle support plate 9.

[0016] In the embodiment, the upper head 1 is an EHA standard elliptical head, the upper head 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com