Improved polymerization reactor

A polymerization reactor, import and export technology, applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the problems of increased impurity acetaldehyde content, consumption of cooling water, and increased impurities. , to achieve the effect of improved catalyst activity, uniform temperature rise and fall, and improved production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

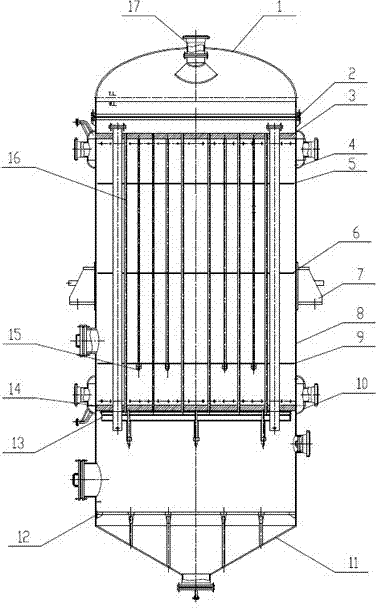

[0015] Example: The polymerization reactor in this embodiment is in the form of a shell-side cylinder and a tube-side heat exchange tube, as shown in the attached figure 1 As shown, the main structure includes an upper head 1, a shell-side cylinder 8, a conical head 11, an upper tube sheet 3, a lower tube sheet 14, and a heat exchange tube 15. The main improvement is that a The upper annular flow channel 4 and the lower annular flow channel 10, and small holes of different diameters are opened in the corresponding positions of the shell-side cylinder 8; three baffle support plates are arranged in the shell-side cylinder 8 along the direction of the heat exchange tubes, and the middle baffle A hole of φ250mm is set in the middle of the support plate 6, and 120 small holes of φ10mm are respectively arranged on the upper baffle support plate 5 and the lower baffle support plate 9.

[0016] In the embodiment, the upper head 1 is an EHA standard elliptical head, the upper head 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com