Forward-extending platform capable of adjusting distance to cab ceiling automatically

An automatic adjustment and cab technology, applied in the direction of motor vehicles, lifting devices, tractor-trailer combinations, etc., can solve problems such as easy collisions, high vehicle heights, and dangers, so as to prevent self-slip, improve operational efficiency and social benefits. benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

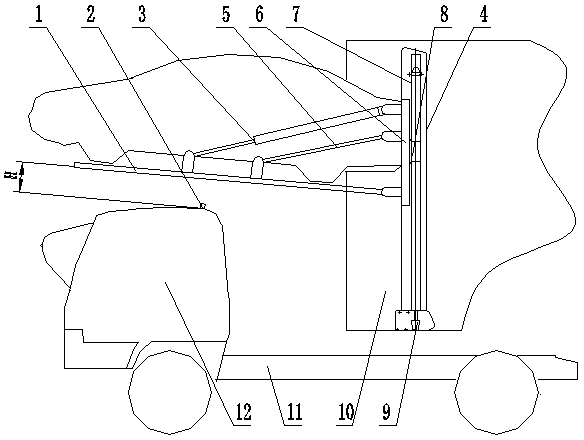

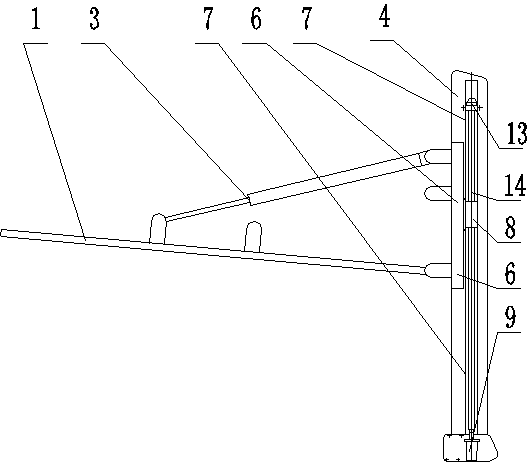

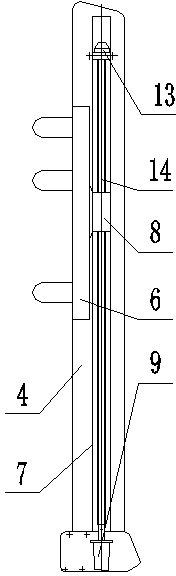

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] refer to Figure 1 to Figure 5 , a forward platform that can automatically adjust the distance from the cab ceiling, it includes a tractor 12, a chassis 11, a vehicle body 10 and a hydraulic station, the tractor 12 is hinged to the chassis 11, and the vehicle body 10 is fixed to the chassis 11. Both sides of the front end of the vehicle body 10 are symmetrically fixed to two hollow columns 4, and sliding grooves are arranged on the surface of the columns 4. The power output shaft of the motor 20 of the hydraulic station is fixedly connected with the power input shaft of the gear pump 19, and the input shaft of the gear pump 19 is fixed. The oil port is sealed and connected with the hydraulic oil tank 21 through the filter 22, the oil outlet of the gear pump 19 is tightly connected with the overflow valve 23 between the check valve 18 and the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com