Small combined spring type quick unfolding mechanism

A technology combining springs and deployment mechanisms, which is applied to self-propelled bombs, weapon types, projectiles, etc., can solve the problems of high cost and large structural space requirements, and achieve the effects of low cost, short processing cycle and strong interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

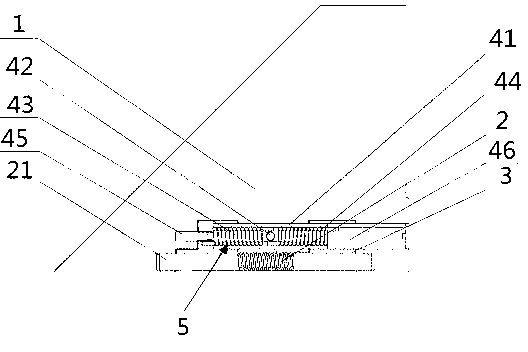

[0016] Such as figure 1 As shown, a small combined spring-type rapid deployment mechanism includes a rudder surface 1 and a compression spring 2 arranged on the rudder surface 1, a rudder seat 3 and a rotating unit; the rudder surface 1 is a right-angled trapezoid; The lower bottom is sequentially provided with a compression spring 2, a rudder seat 3 and a rotating unit from bottom to top. A locking pin 21 is respectively arranged on both sides of the compression spring 2 . Arrange two locking pins 21 and a compression spring 2 into the installation hole of the rudder seat 3 according to the diagram, use tooling to make the two locking pins 21 move toward each other, compress them in place, and snap them into the limiting taper hole of the rudder surface 1; The rudder surface 1 and the rudder seat 3 are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com