Method and device for measuring functional characteristic parameters of three-dimensional surface topography of roll and strip steel

A technology of three-dimensional surface and functional characteristics, applied in the field of strip rolling, can solve the problems of high operating environment requirements, complicated operation, and large roll volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

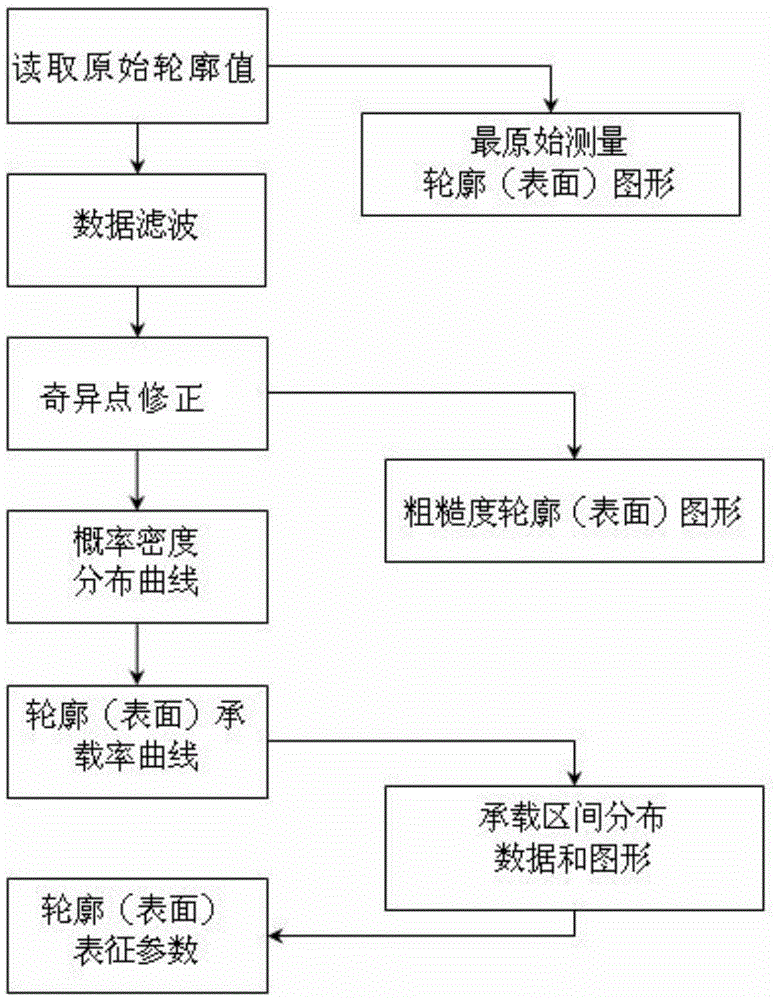

[0064] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

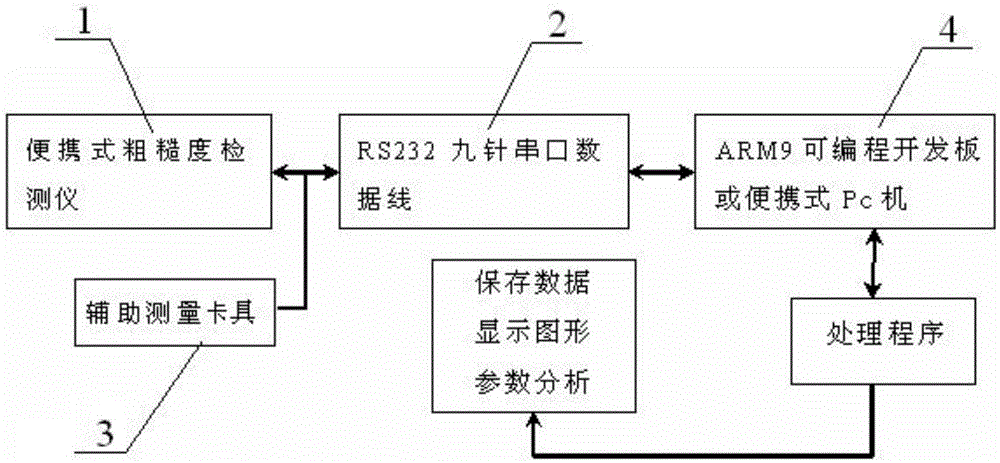

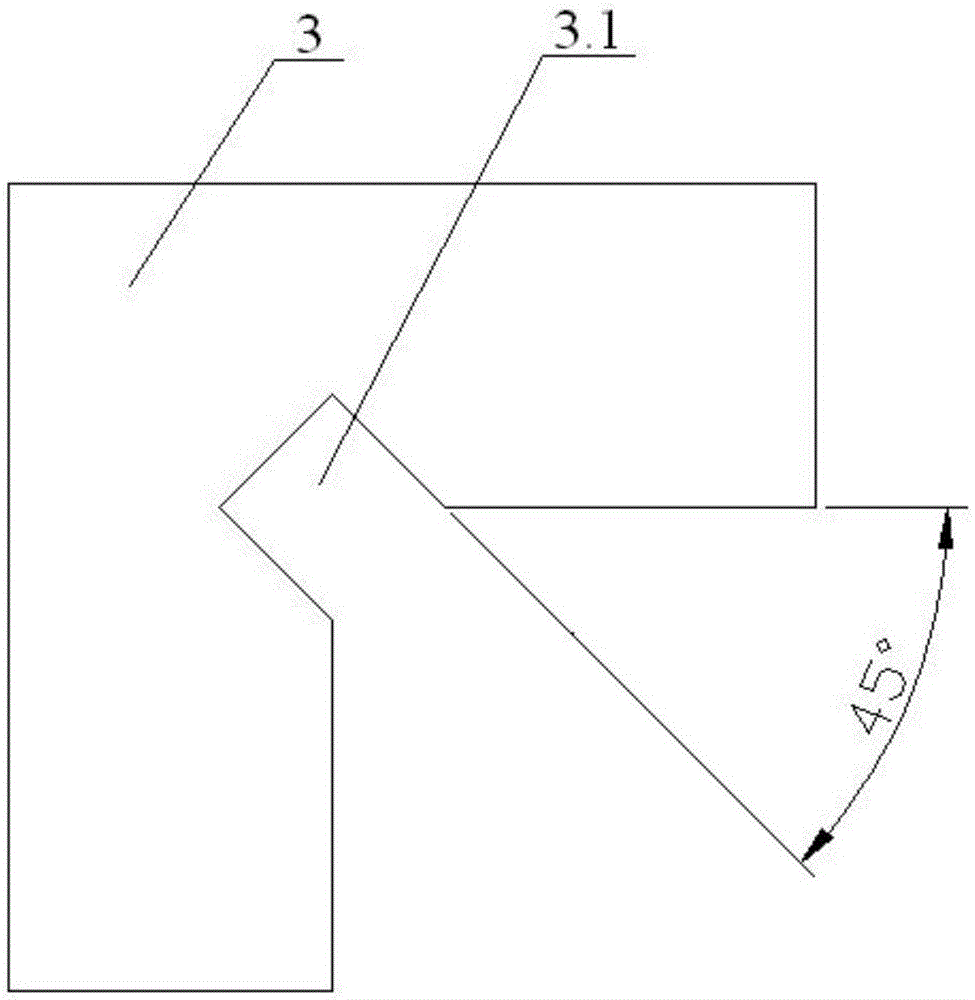

[0065] like figure 1 , 2 As shown, the measuring device for the functional characteristic parameters of the three-dimensional surface topography of the roll and strip steel includes a portable roughness detector 1, an RS232 nine-pin serial data line 2, an auxiliary measuring fixture 3 and an ARM9 programmable development board or a portable PC 4 , the output end of the portable roughness detector 1 is connected with the input end of the ARM9 programmable development board or the portable PC 4 through the RS232 nine-pin serial data line 2 . Its basic composition is described in detail as follows:

[0066] (1) Portable roughness detector

[0067] The data acquisition of this system mainly relies on the M1 handheld roughness meter, which is suitable for the production site and can measure the surface roughness of various machined part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com