Method for obtaining stress-strain curve of filling body test block through common press

A technology of strain curve and filling body, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem of inability to measure the load-displacement curve and stress-strain curve of the filling body test block, so as to reduce the error. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

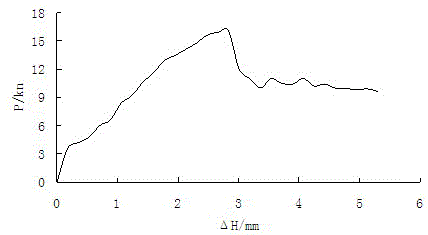

[0019] The method of the present invention is: measure the height H=13.6cm of the cement-tailing sand filling body test block, the diameter R=6.6cm, and calculate the pressure-bearing surface area S=34.19cm 2 , prepare the digital camera to shoot the video of the test process. Turn on the NYL-300 ordinary press, adjust the rising loading speed of the lower platen V=0.177mm / s, wait until the pressure-bearing surface of the filling body test block touches the upper platen of the press, the pointer of the press will gradually deflect on the reading dial, and then turn on the digital The camera shoots a video of the whole process of pointer deflection on the reading plate of the press, and records the whole process from when the filling body test block begins to bear the pressure P to when the filling body test block is destroyed and unloaded. Transfer the captured video to the microcomputer, start from the test block of the filling body to bear the pressure, play back the video w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com