Testing method for guiding hole coppering thickness in wiring board

A test method and via hole technology are applied in the field of measuring copper plating thickness of via holes in flexible circuit boards on production lines, which can solve problems such as damage to products and waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

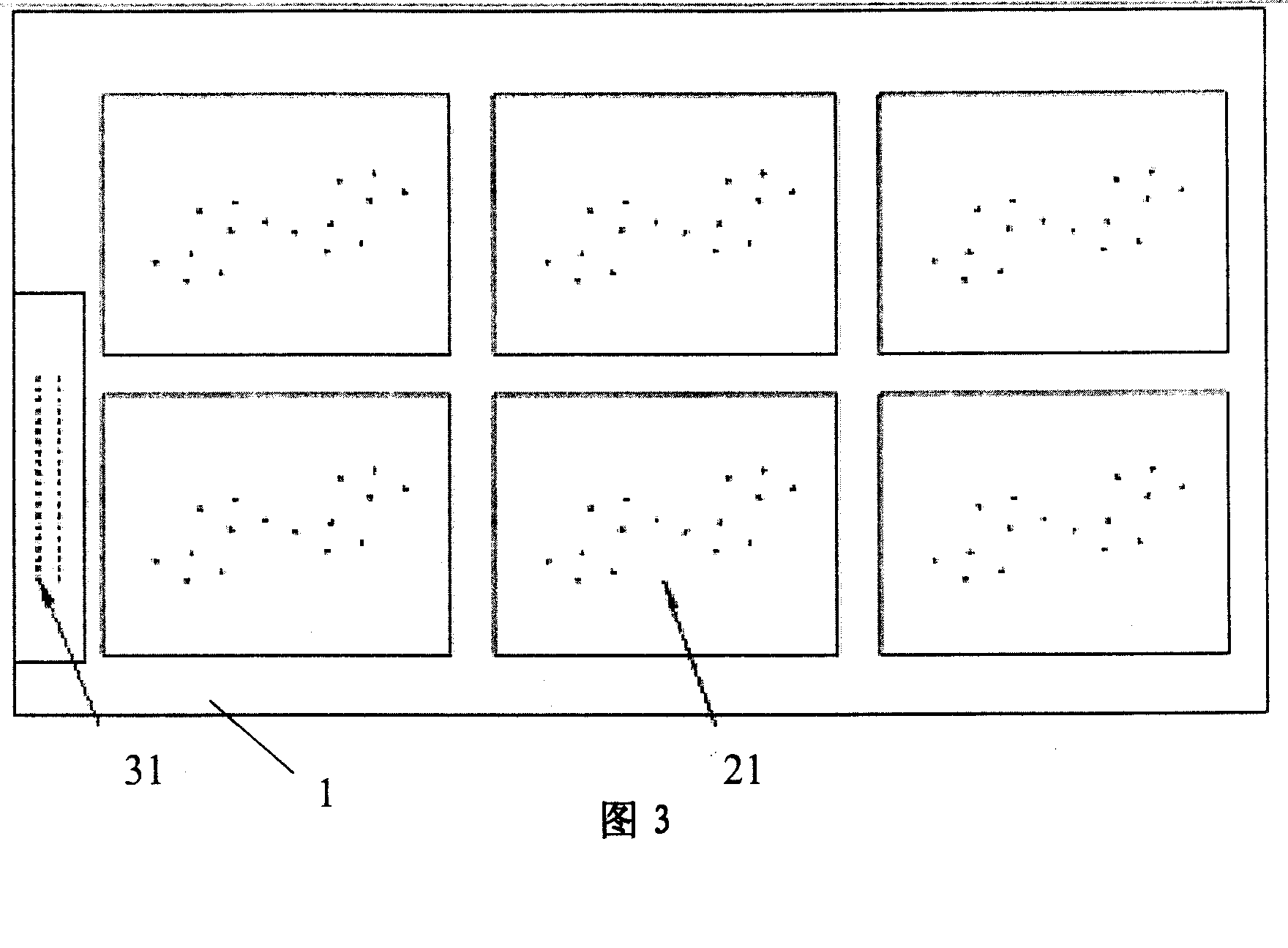

[0021] In a four-layer flexible printed circuit board product, the size of the via hole in the product is 0.25mm and 0.3mm. The specific implementation method is as follows: firstly, when drilling holes after cutting the copper foil, 20 0.25mm and 20 0.3mm two kinds of drilling holes are added in the scrap copper area, and the arrangement is shown in Figure 3. Copper plating is carried out by the hole plating process. After the copper plating is completed, it is cut off, and the hole section is analyzed, and the thickness of the hole copper is measured on a metallographic microscope (Jenco Instruments Inc. Model MET-233). The test results are listed in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com