Touch panel and touch display device provided with same

A touch panel, touch display technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc. Enhance the anti-ESD ability and reduce the effect of misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

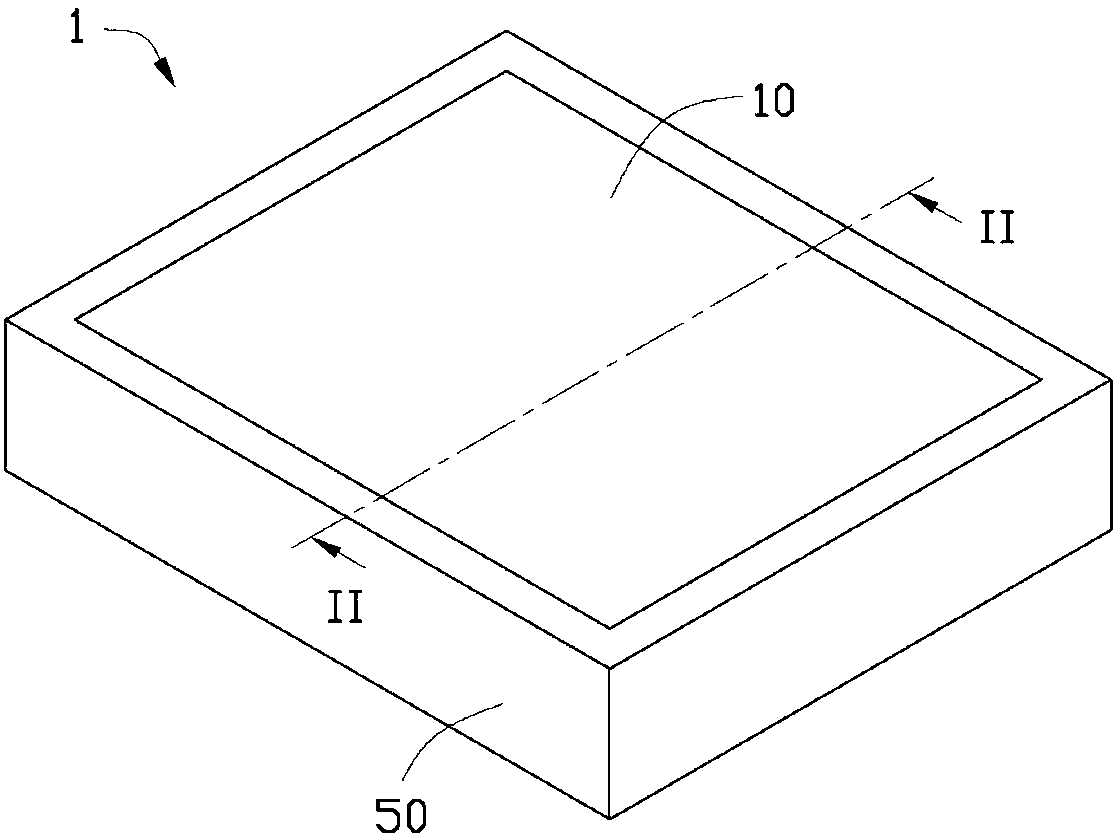

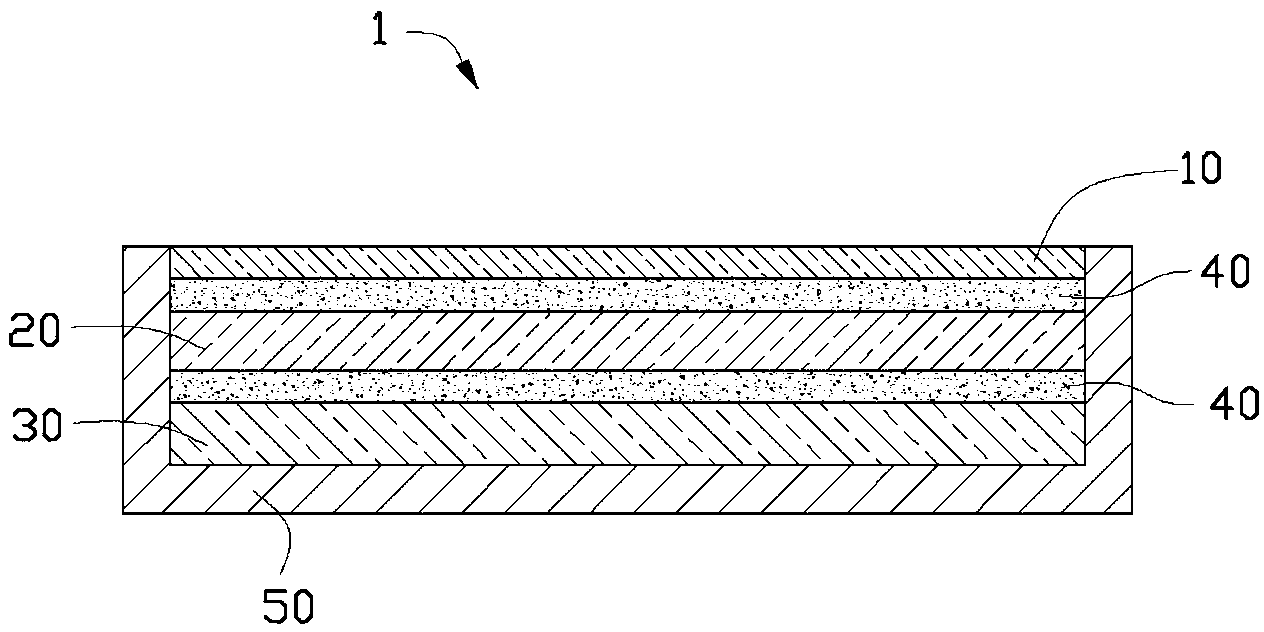

[0015] see figure 1 and figure 2 , the touch display device 1 provided by the present invention includes a glass cover 10 , a touch panel 20 , a display module 30 and a casing 50 . The touch panel 20 and the display module 30 are accommodated in the accommodation space formed by the glass cover 10 and the casing 50 .

[0016] The glass cover 10 , the touch panel 20 and the display module 30 are stacked with each other. The touch panel 20 is glued together with the glass cover 10 and the display module 30 through optical glue 40 . The optical glue 40 may be, but not limited to, an adhesive with high light transmittance such as optical clear adhesive (Optical Clear Adhesive, OCA) or optical clear resin (Optical Clear Resin, OCR).

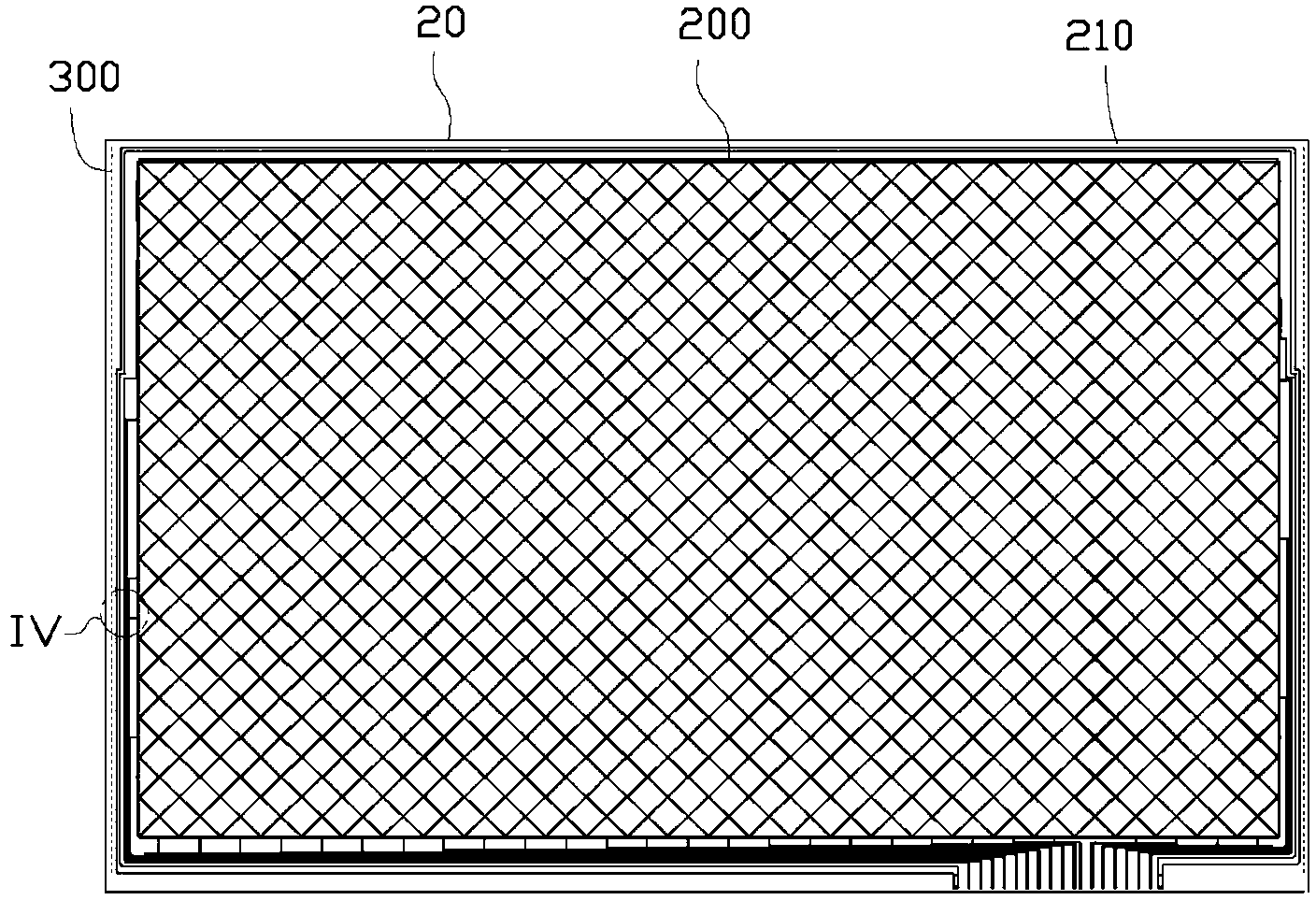

[0017] see image 3 As shown, the touch panel 20 includes a touch area 200 and a wiring area 210 located around the touch area 200 and surrounding the touch area 200 . The wiring area 210 is used for wiring design of the conductive signal lines ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com