Constrained knee prosthesis

A knee joint prosthesis and prosthesis technology, applied in the field of knee joint prosthesis, can solve problems such as biomechanical inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

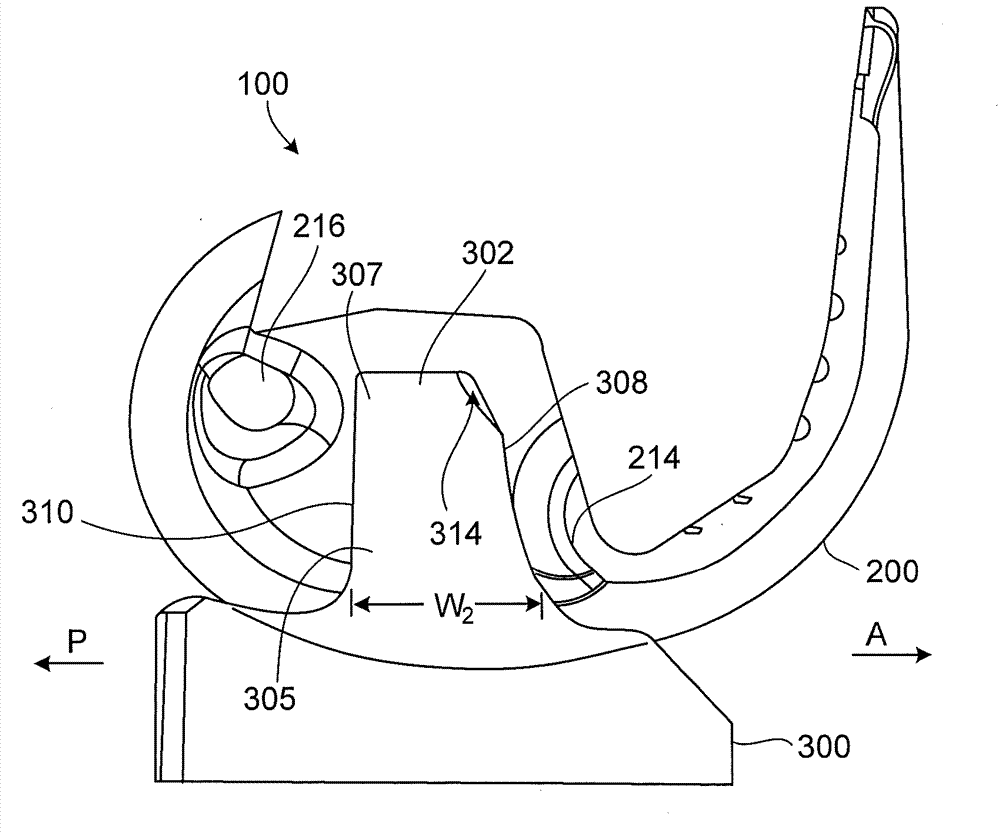

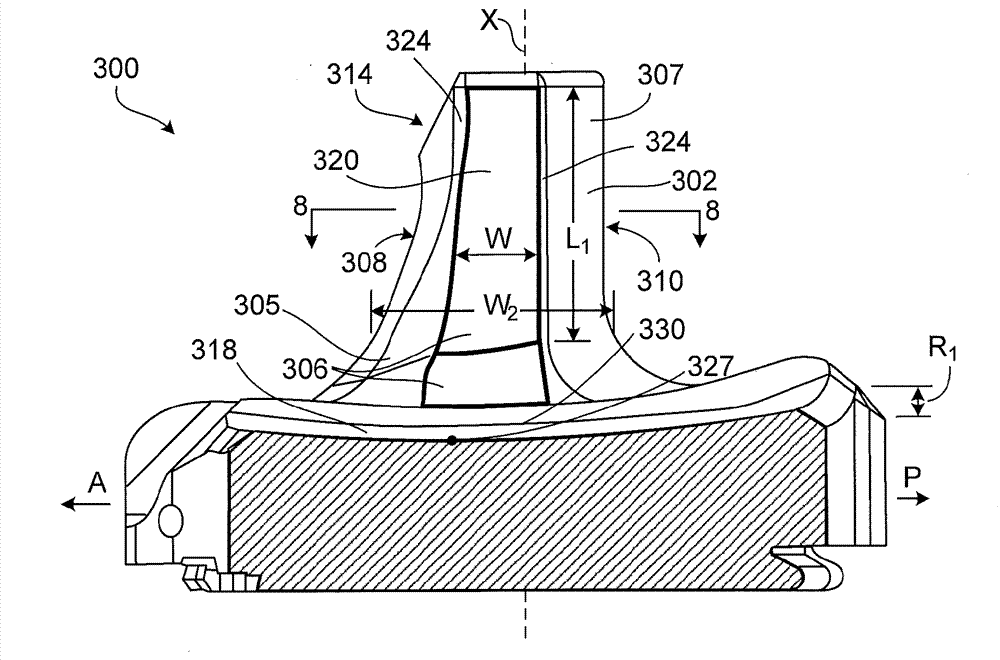

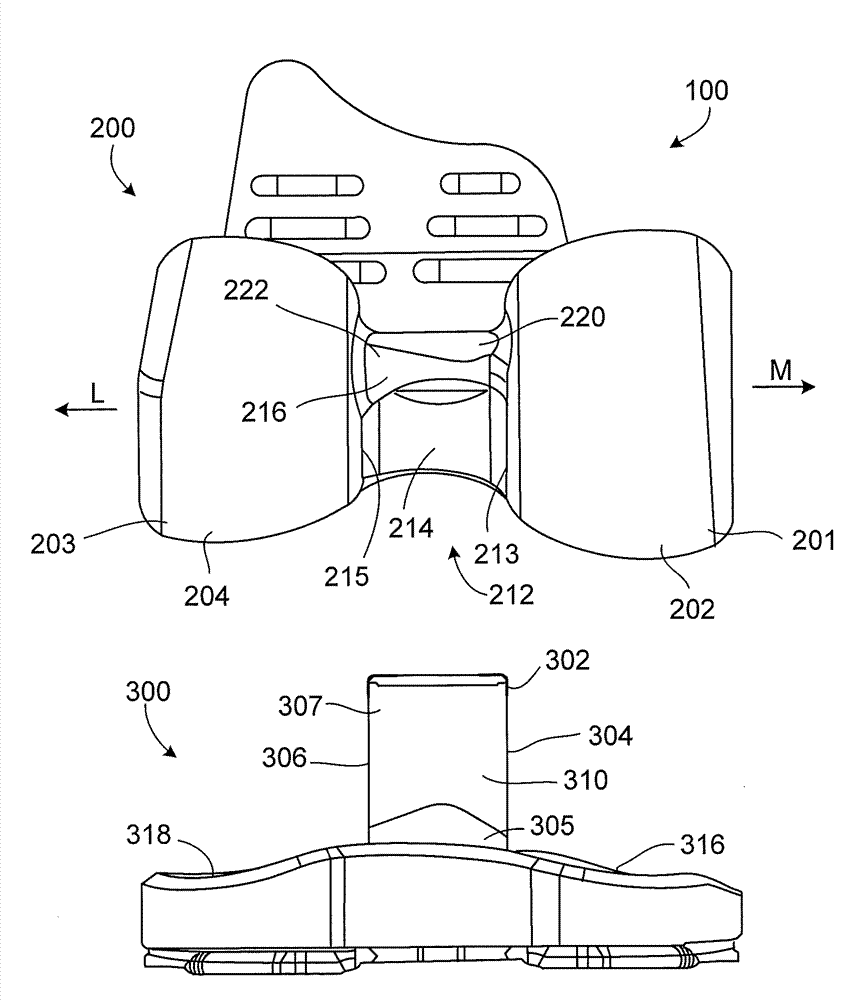

[0023] refer to figure 1 and 2 , the knee prosthesis 100 provides varus / valgus constraint and also allows internal and external rotation of the tibia relative to the femur. To this end, knee prosthesis 100 includes tibial insert 300 that is shaped to engage femoral component 200 to (i) limit tibial varus-valgus deviation from its proper alignment with the femur, and (ii) promote tibial Rotation relative to the femur during flexion. Tibial insert 300 may be referred to as a constrained insert that is constrained by femoral component 200 in assembled knee prosthesis 100 .

[0024] During flexion in a healthy knee, the tibia rotates a small amount about its longitudinal axis (internal-external rotation). Knee prosthesis 100 enables this rotation to help maintain a natural feel for the reconfigured knee. Internal rotation of the tibia relative to the femur (tibiofemoral rotation) aligns the line of action of the quadriceps with the tibia, improving quadriceps efficiency compar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com