Transparent force sensor and method of fabrication

A transparent conductive, transparent substrate technology, applied in the direction of instrumentation, force measurement, calculation, etc., can solve the problems of environmental interference, limited spatial resolution of capacitive pressure sensors, etc., and achieve the effect of simplifying the input process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following detailed description is merely exemplary in nature and is not intended to limit the invention or the application and uses of the invention. Furthermore, there is no intention to be bound by any theory presented in the preceding background or the following detailed description.

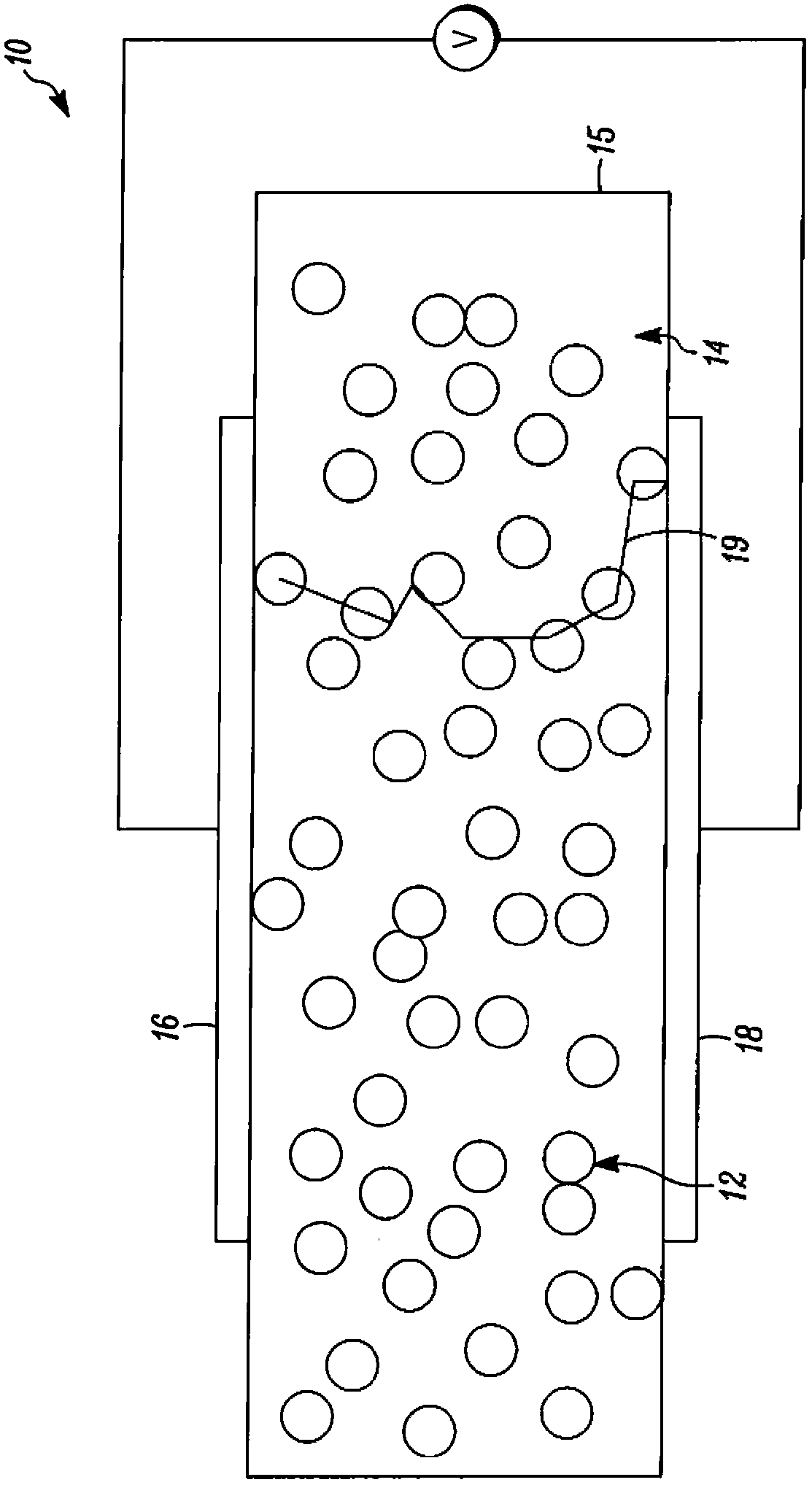

[0026] refer to figure 1 , discloses a transparent touch screen sensor 10 . Sensor 10 may be implemented in various electronic devices with displays, including but not limited to mobile computers, computer monitors, mobile phones, personal digital assistants (PDAs), and kiosks. The sensor 10 is configured to detect a touch by measuring a localized pressure exerted on a display area such as a touch screen. Advantageously, sensor 10 allows analysis of a third dimensional input, namely force, in addition to time and position input, enabling a whole new range of applications.

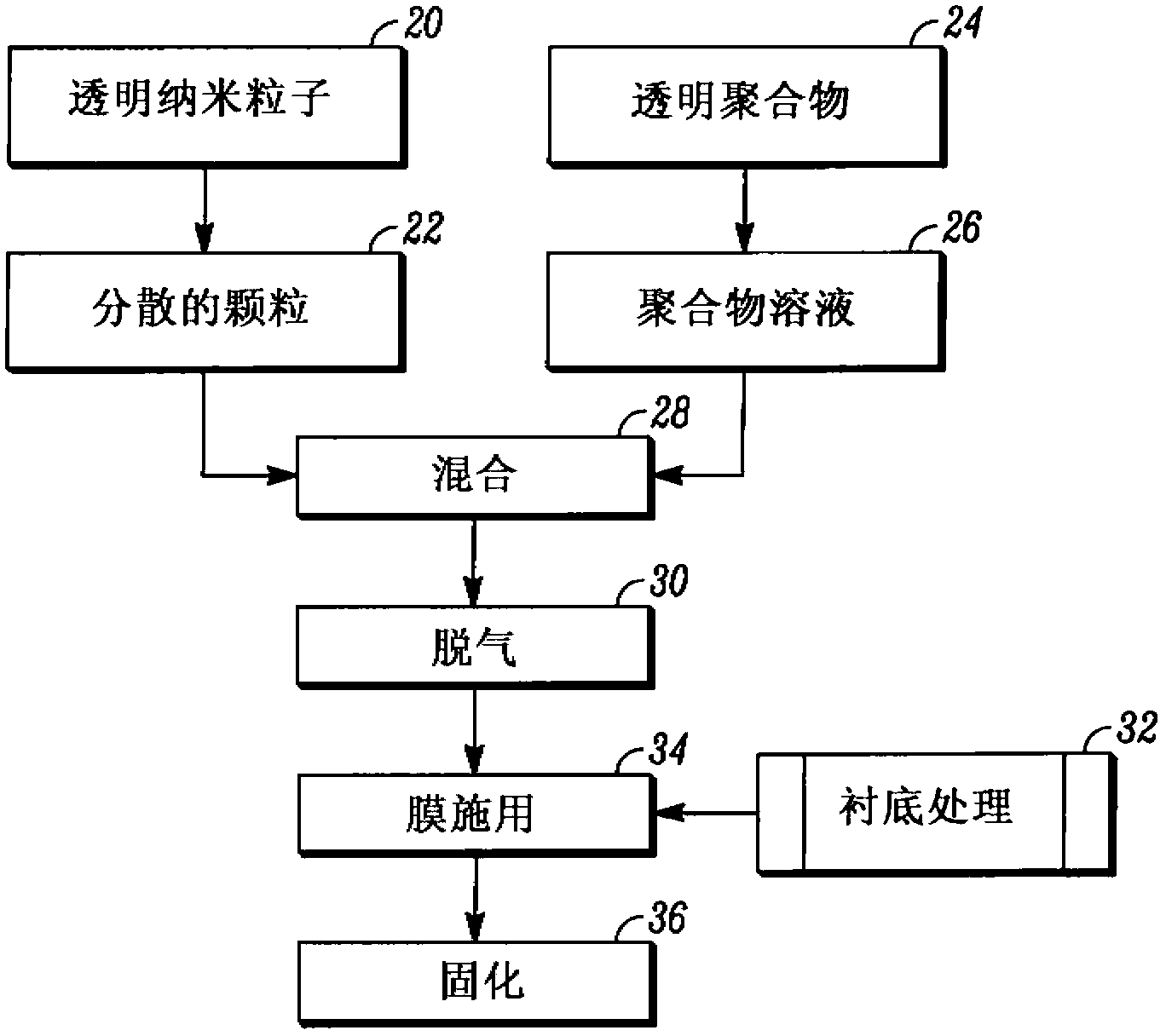

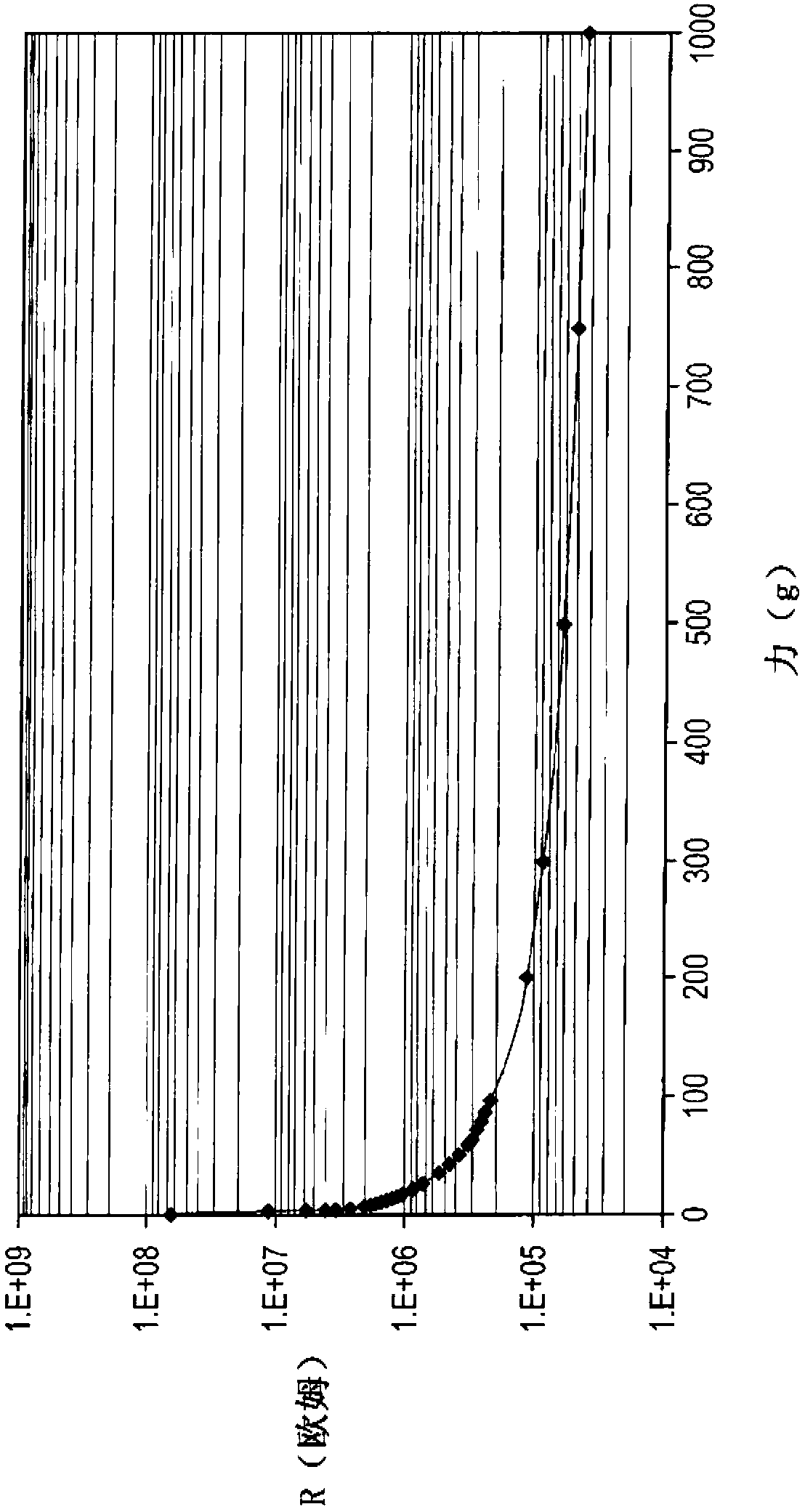

[0027] In one embodiment, the sensor 10 includes a force-sensing transparent polymer-conductor composite (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com