Clamping device of injection molding machine mould

A technology for injection molding machines and molds, which is applied in the field of clamping devices for injection molding machine molds, and can solve the problems of pads 23 not being installed in place, unreliable clamping, and low clamping efficiency, so as to achieve fast and convenient clamping and avoid padding Insufficient installation, good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

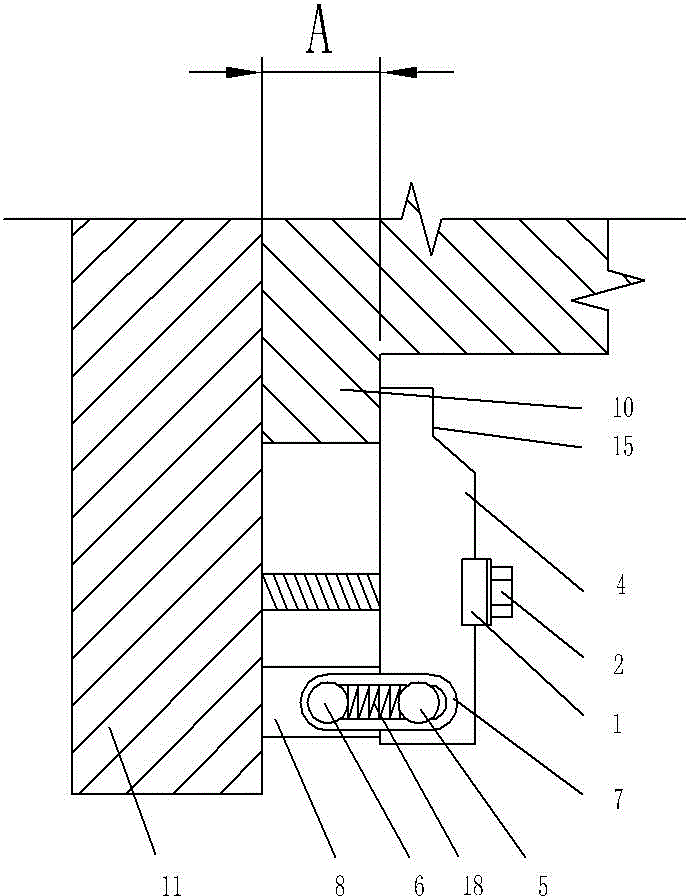

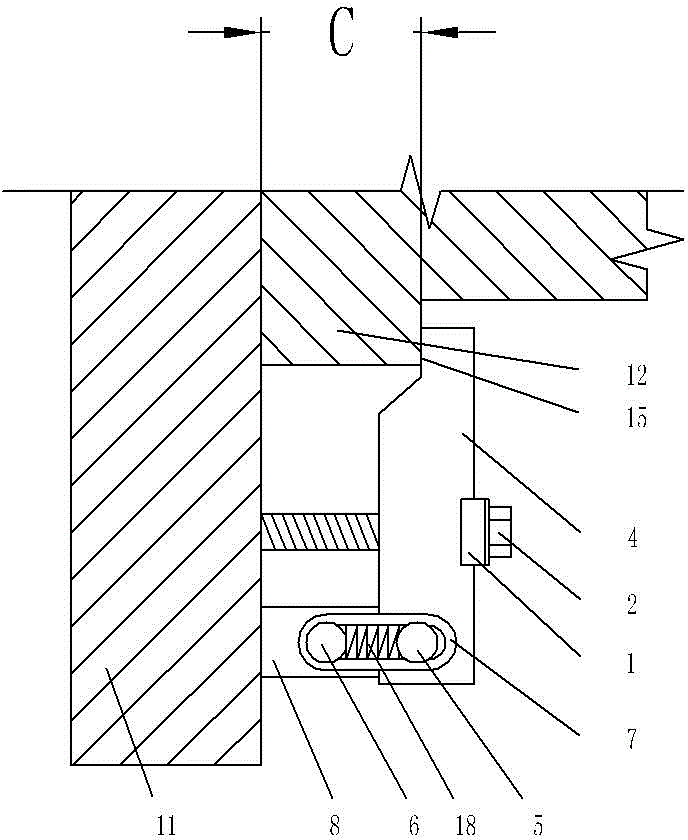

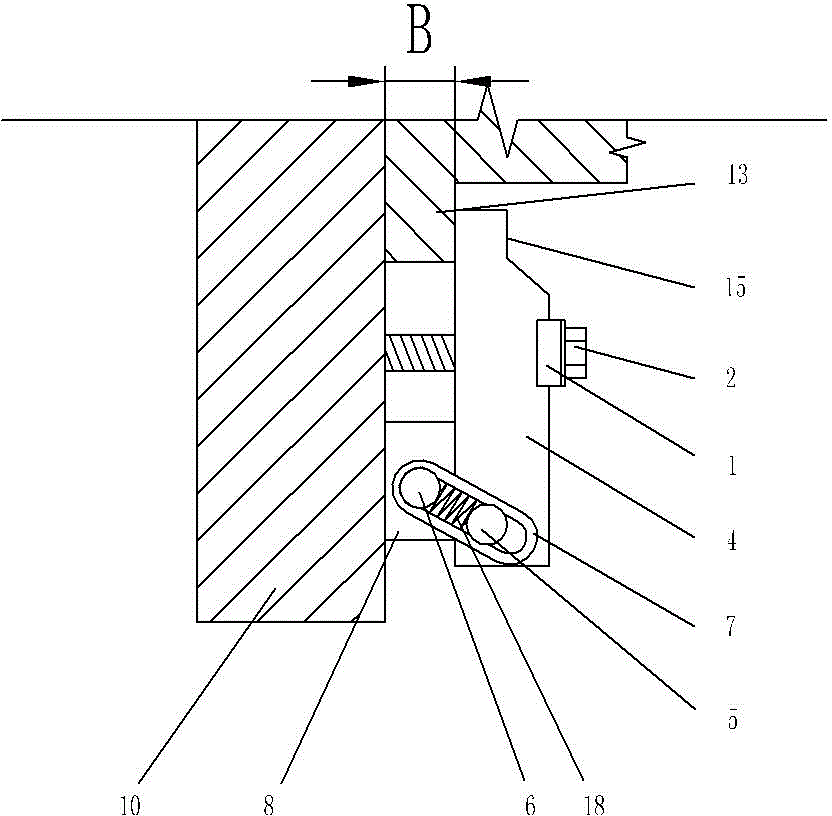

[0019] Such as Figure 1 to Figure 5 As shown, the clamping device of the injection molding machine mold includes a compression bolt 2, a clamp block 4 and a pad 8. The thickness of the pad 8 is the same as the thickness of the flange of the mold installation end, and the pad 8 is installed on the clamp block 4 and the injection molding Between the machine installation surface 11, the clamping bolt 2 passes through the clamp block 4 and presses the clamp block 4 on the mold and the cushion block 8, thereby clamping the mold on the injection molding machine installation surface 11, the cushion block 8 and the clamp block 4 is connected through the side connection block 7, the clamping block 4 and the cushion block 8 are respectively connected with the side connection block 7 through the first shaft pin 5 and the second shaft pin 6; the side connection block 7 has a waist hole 16, the first shaft pin 5, the shaft pin After the second 6 passes through the waist hole 16, it is hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com