Take-up device capable of automatically adjusting take-up radius

A technology of automatic adjustment and take-up device, applied in the directions of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of inability to carry out, inconsistent take-up radii of copper rods, etc., to avoid uniform take-up radii. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

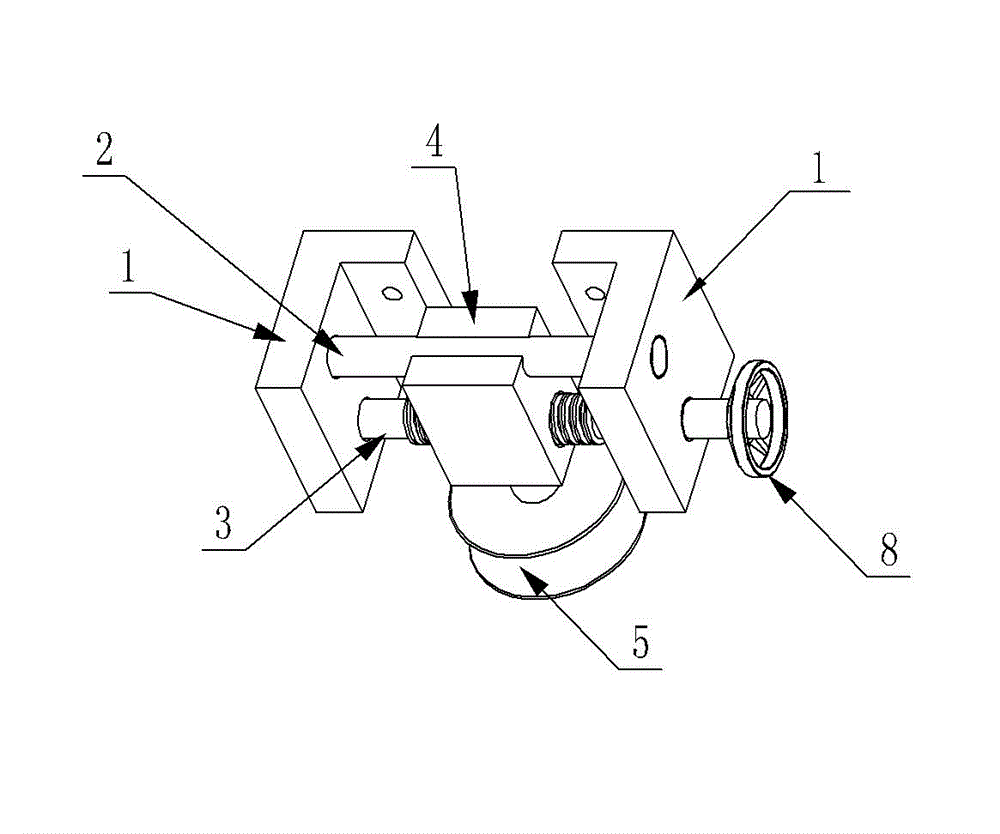

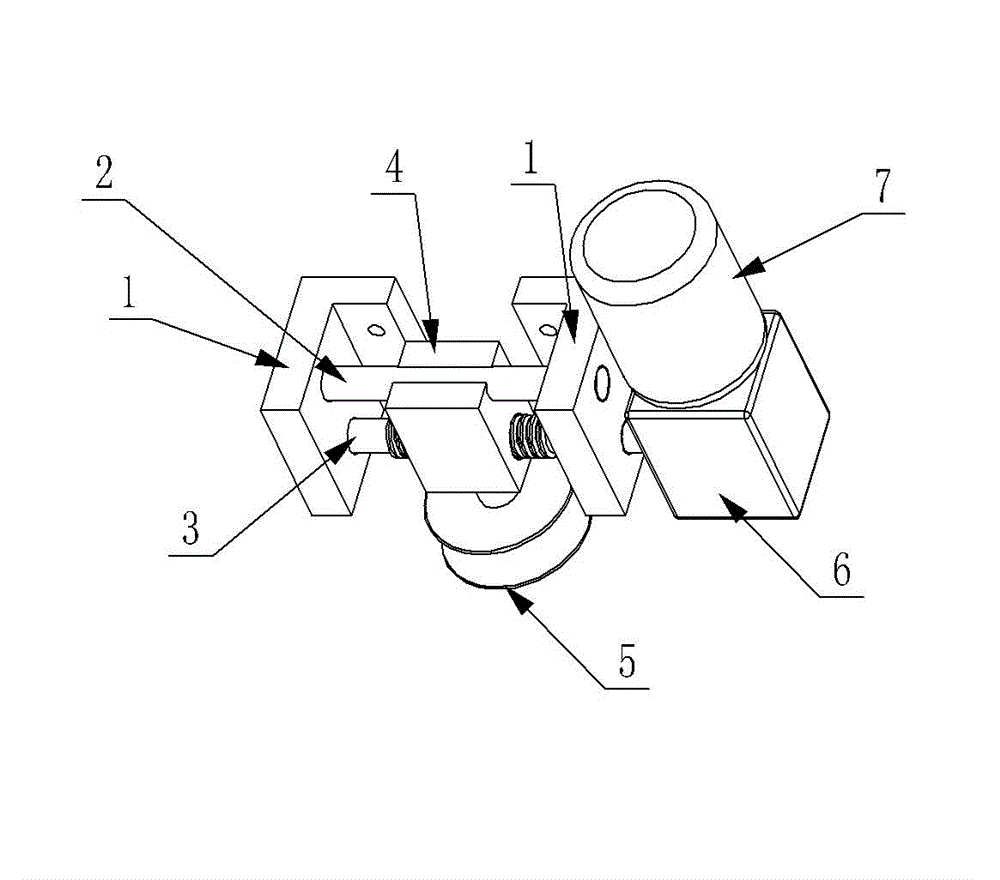

[0008] See figure 2 , the device of the present invention comprises a bracket 1, a positioning rod 2, a cable screw 3 and a cable nut 4, the positioning rod 2 and the cable screw 3 are installed on the bracket 1 in parallel, the cable nut 4 is threadedly connected with the cable screw 3, and the row The upper end of the wire nut 4 is engaged with the positioning rod 2 and can slide along the positioning rod 2, and the lower end of the wire nut 4 passes through the bearing ( figure 2 not shown in ) is equipped with a cable guide wheel 5, the cable screw 3 is connected to the output end of the worm gear reducer 6, the worm gear reducer 6 is electrically connected with the three-phase asynchronous motor 7, and the three-phase asynchronous motor 7 is electrically controlled Frequency conversion controller 9 ( figure 2 not shown).

[0009] When the device of the present invention works, the three-phase asynchronous motor 7 is controlled by a frequency converter controller, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com