An efficient automatic seeding device

A seeding device and high-efficiency technology, which is applied in the field of efficient automatic seeding devices, can solve the problems of many control parts and transmission parts, high energy consumption and maintenance costs, and high labor intensity, and achieve low cost of use and difficulty in maintenance and care The effect of small size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

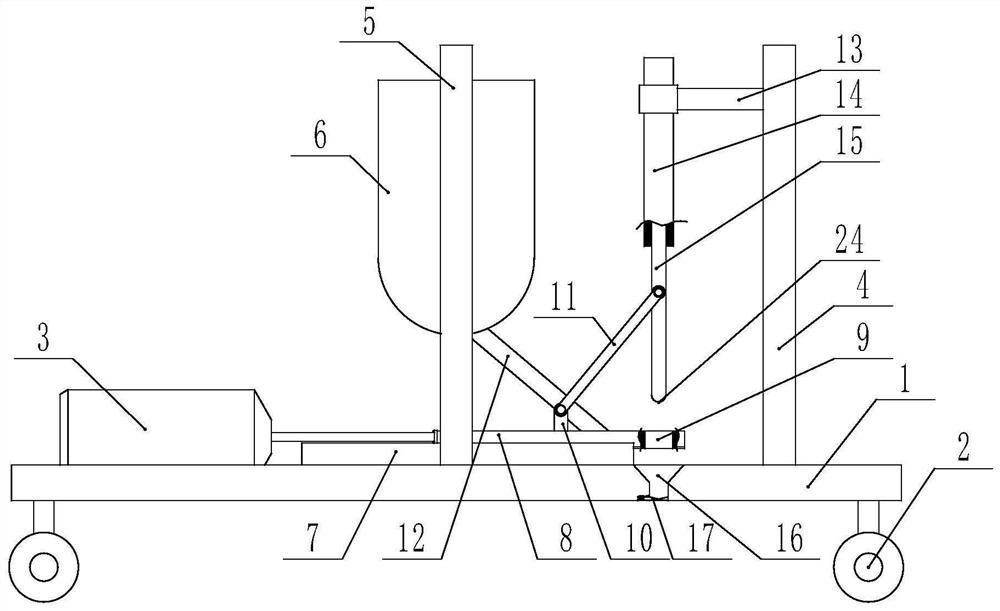

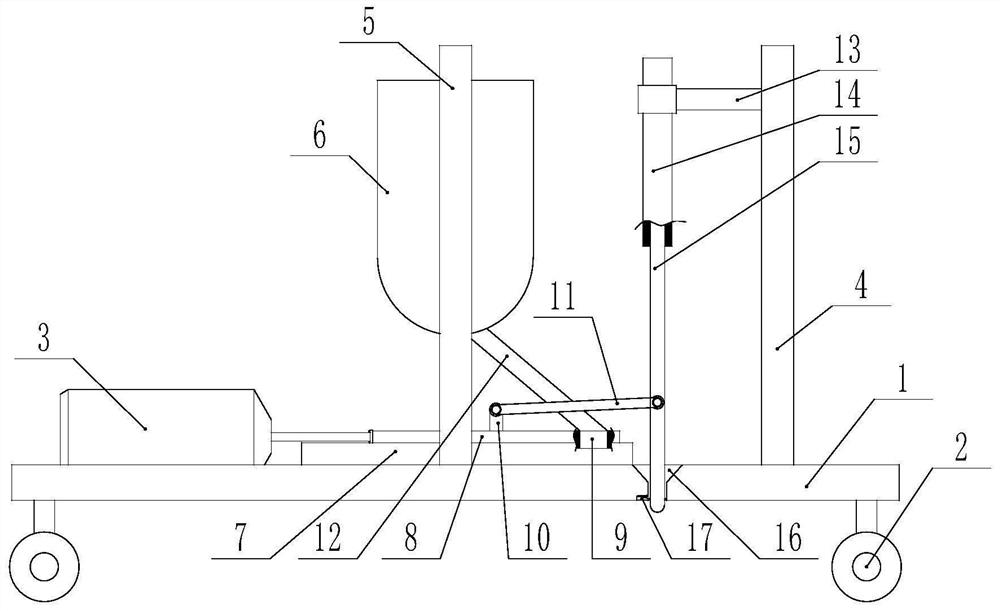

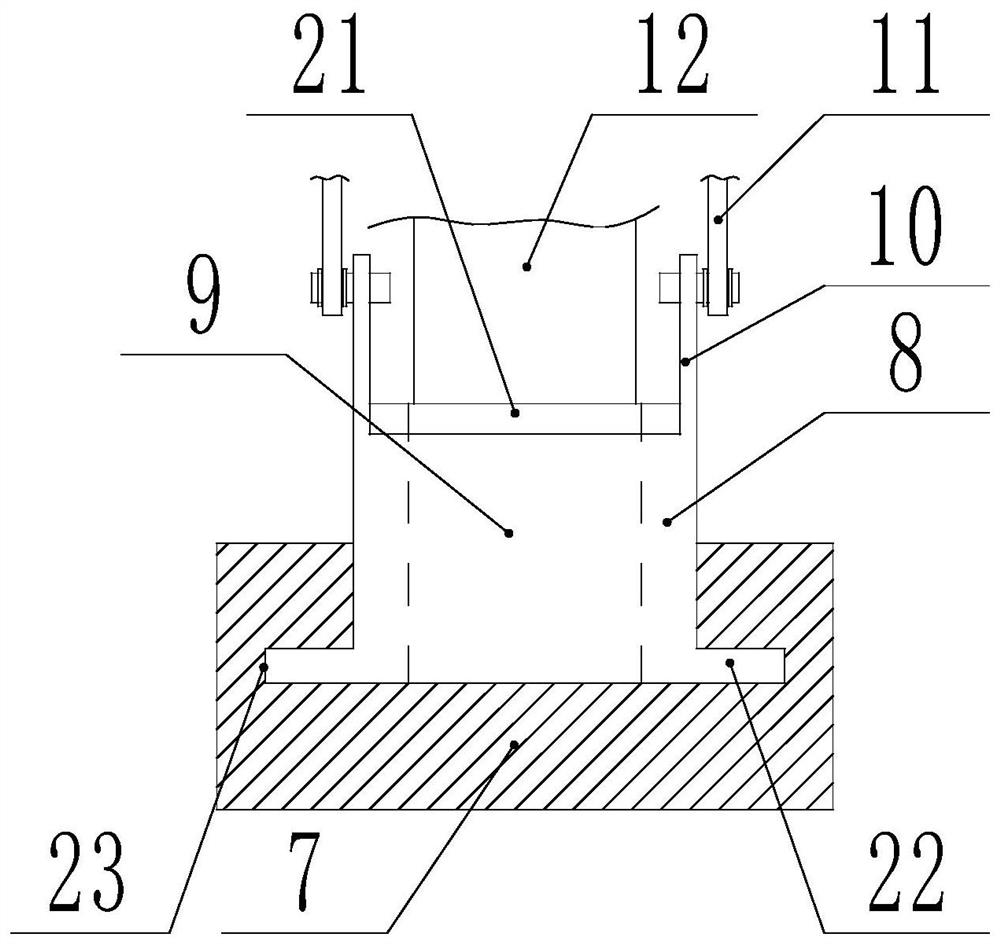

[0027] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, the inventive point of the present application is that the cylinder 3 is fixedly installed at one end of the upper surface of the base, the column 4 is fixedly installed at the other end of the upper surface of the base, and the support frame 5 is also fixedly installed on the upper surface of the base, and the support frame is located at Between the cylinder and the column, the seed storage box 6 is fixedly installed on the support frame,

[0028] A slideway 7 is fixedly installed on the upper surface of the base, and the slideway is located between the cylinder and the column. The slideway passes through the support frame horizontally. Sliding in the length direction, one end of the slide plate is fixedly connected with the telescopic end of the cylinder, and the other end of the slide plate is provided with a circular hole 9, and the circular hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com