Full-automatic fresh and wet rice noodle production device and application thereof

A production device and fully automatic technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of pattern on the surface of rice milk, poor thermal conductivity of cloth tape, and short shelf life of rice noodles, so as to achieve smoothness on both sides, increase production capacity, and taste tender effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

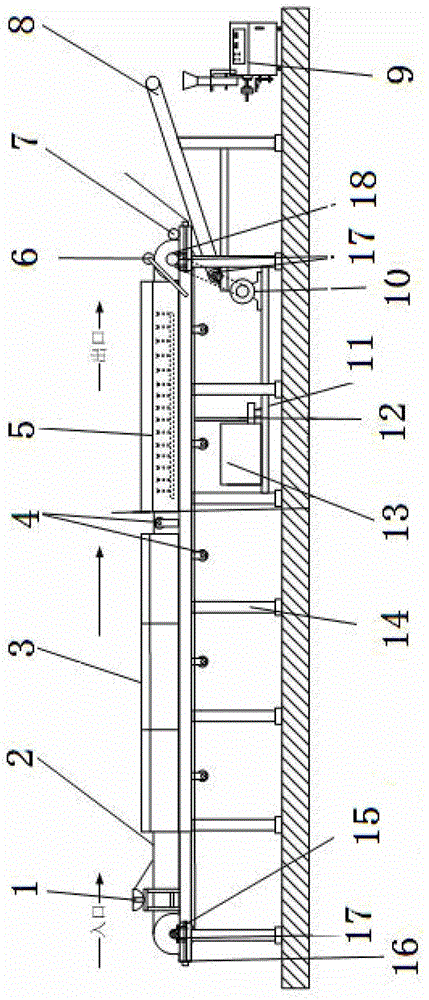

[0022] The present invention will be further described below in conjunction with the accompanying drawings and applications.

[0023] The structure of the full-automatic fresh wet rice noodle production device of the present invention is as follows: figure 1 As shown in the figure, rice milk splitter 1, food-grade stainless steel conveyor belt 2, high-temperature cooking box 3, towing drum 4, water cooling box with spray device 5, horizontal and vertical roller cutter 6, adjustable speed separation and cutting Knife 7, lifting conveyor 8, packaging machine 9, main mechanism motor 10, water pump 11, cooling water pipe 12, circulating water tank 13, frame 14, driving roller 15, adjusting tension device 16, bearing, bearing seat 17, main Drive roller 18.

[0024] On the frame 14, from the entrance to the exit, there are: transmission roller 15, rice milk splitter 1, high-temperature cooking box 3, dragging drum 4, cooling water tank 5, horizontal and hard cutting roller knives 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com