Construction hoist with built-in balance weights

A construction elevator, built-in technology, applied in elevators, elevators in buildings, transportation and packaging, etc., can solve the problems of elevators that are prone to safety and hidden dangers, and achieve the effect of reducing labor intensity and improving safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

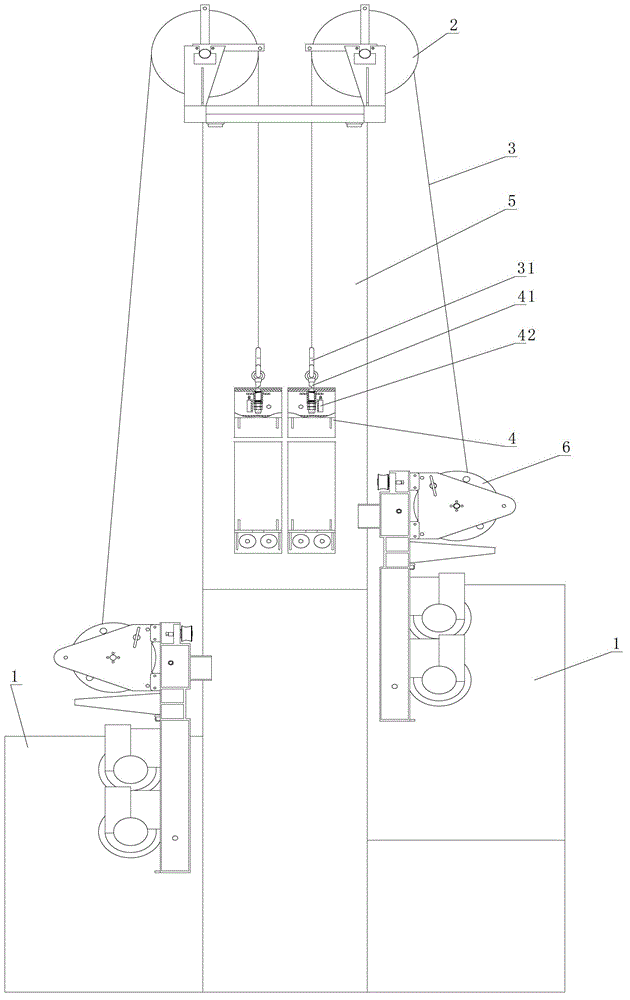

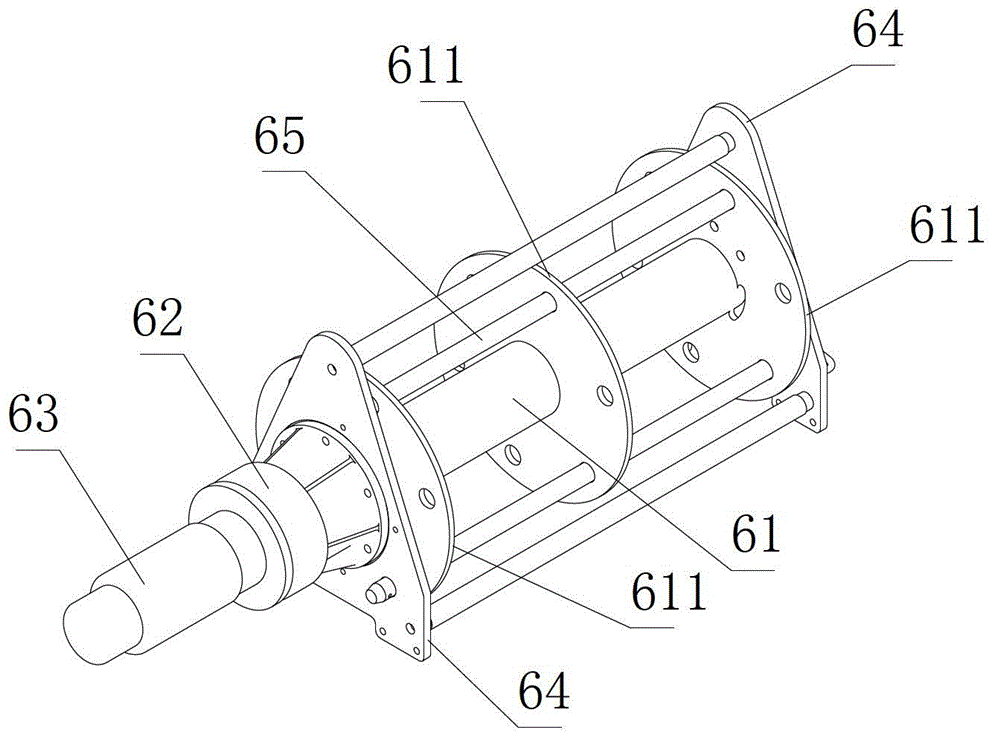

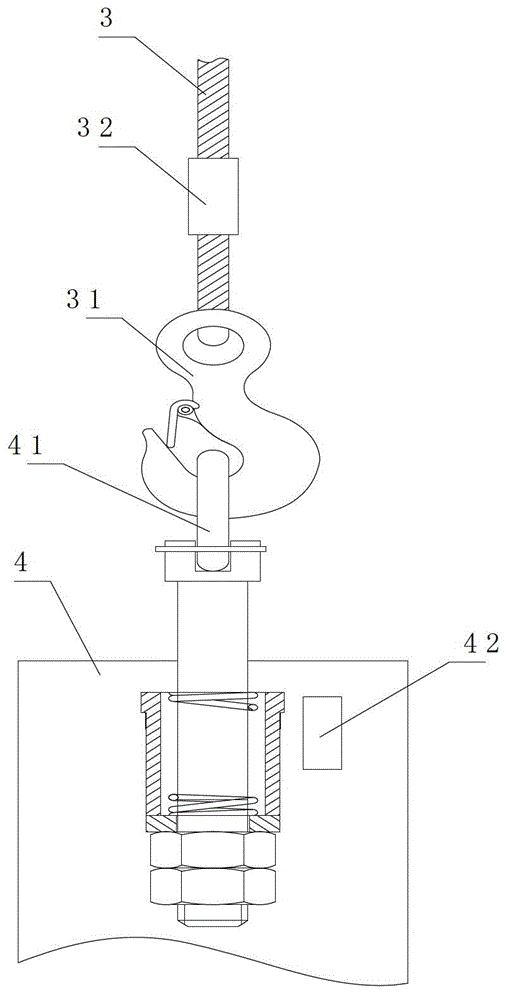

[0026] Such as Figure 1 to Figure 10 As shown, the counterweight built-in construction hoist includes a hanging cage 1, a wheel frame 2 wound with a steel wire rope 3, a counterweight body 4 connected to one end of the steel wire rope 3, a guide frame 5, and a wall frame fixed on the guide frame 5. It includes a hoisting assembly 6 connected to the other end of the steel wire rope 3, the hoisting assembly 6 is connected to the cage 1, the steel wire rope 3 is provided with a connecting device 31 connected to the counterweight body 4, and the counterweight body 4 is provided with The connecting piece 41 that cooperates with the connecting device 31, the top of the counterweight body 4 is provided with a limit device 42, and the cage 1 is provided with an interlock assembly for the safe opening of the cage safety door and a protective door for the normal opening of the cage protective door Electromechanical interlocks, such as figure 2 , image 3 As shown, the hoisting assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com