Stop screw component

A screw assembly and anti-loosening technology, which is applied in the direction of pins, connecting components, mechanical equipment, etc., can solve problems that affect the performance and stability of mechanical equipment, safety accidents, and affect processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

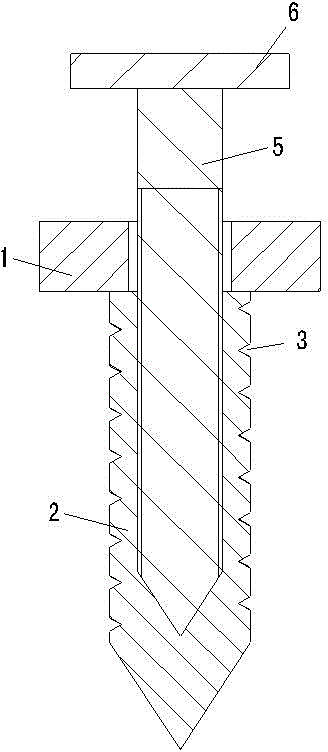

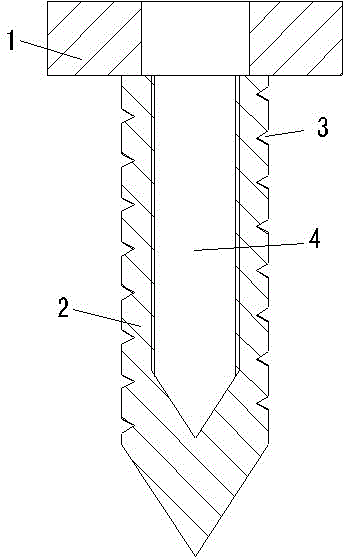

[0013] as attached figure 1 , 2 The shown anti-loosening screw assembly of the present invention includes a fastening screw and an extrusion screw; the fastening screw includes a first screw head 1 and a first screw shaft 2; the first screw shaft 2 It is arranged on the first screw head 1; the first screw rod 2 is provided with an external thread 3; the middle part of the first screw head 1 and the first screw rod 2 is provided with a connected threaded hole 4; the extrusion The screw comprises a second screw rod 5 and a second screw head 6; the second screw head 6 is arranged on the second screw rod 5; the second screw rod 5 is provided with external threads; the second screw rod 5 is arranged in the threaded hole 4; the external thread 3 provided on the first screw rod is consistent with the rotation direction of the external thread provided on the second screw rod; the threaded hole 4 is provided with a taper; when the second screw rod 5 When screwed in, the first threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com