Electronic device, and assembly method and bonding structure of cover plate of electronic device

An electronic device and assembly method technology, applied in chemical instruments and methods, electrical digital data processing, input/output process of data processing, etc., can solve the problems of light leakage at the edge and affect the display effect, and achieve the effect of improving the display quality of the screen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

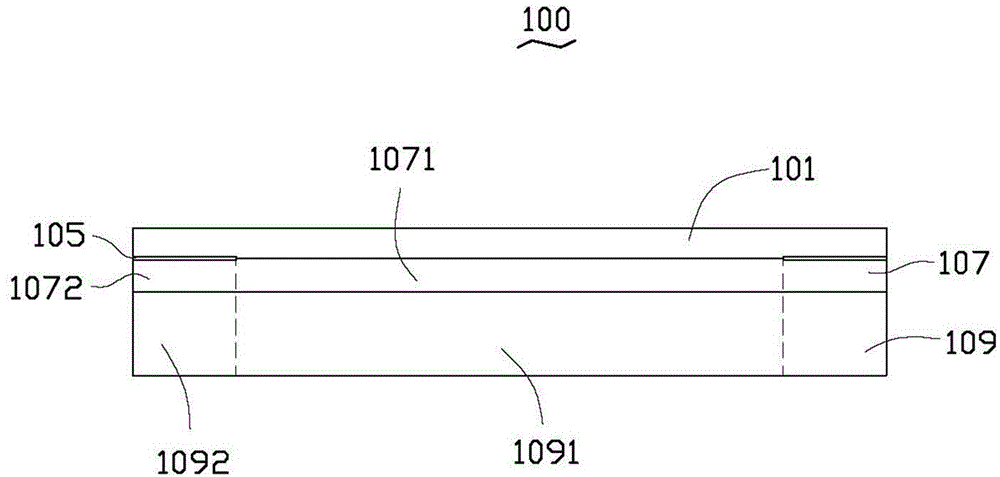

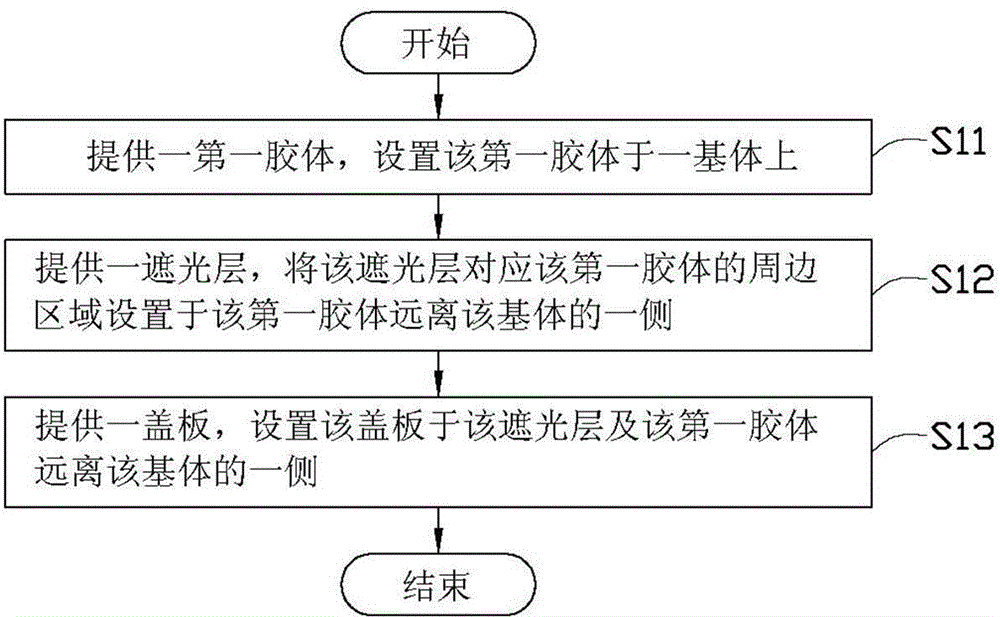

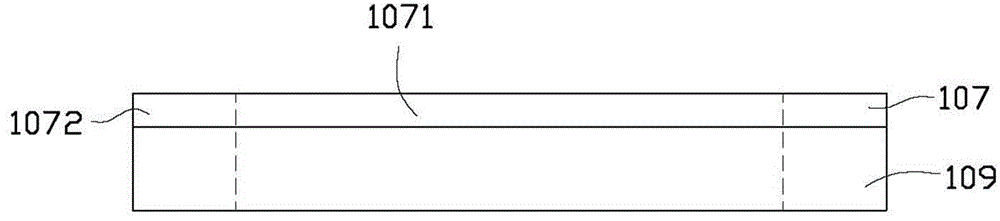

[0021] see figure 1 , the electronic device 100 may be a liquid crystal display device, a touch control device, or the like. The electronic device 100 includes a base body 109 , a first colloid 107 , a light shielding layer 105 and a cover plate 101 . The first colloid 107 is disposed on the base body 109 . The first colloid 107 has a middle region 1071 and a peripheral region 1072 disposed at the edge of the middle region 1071 . The light shielding layer 105 is disposed on the surface of the first colloid 107 away from the substrate 109 corresponding to the peripheral region 1072 . The cover plate 101 is disposed on the side of the light shielding layer 105 away from the first colloid 107 . In this embodiment, the cover plate 101 is a transparent cover plate, such as a glass cover plate. The substrate 109 can be a touch sensing film or a liquid crystal panel, etc., and includes a main functional area 1091 and a peripheral wiring area 1092 connected to the edge of the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com