Method for determining fatigue strength of engine components

A fatigue strength, engine technology, applied in the test of the engine, the test of the machine/structural component, the use of the applied stable tension/pressure to test the strength of the material, etc., can solve the problem that the matching relationship is not completely reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

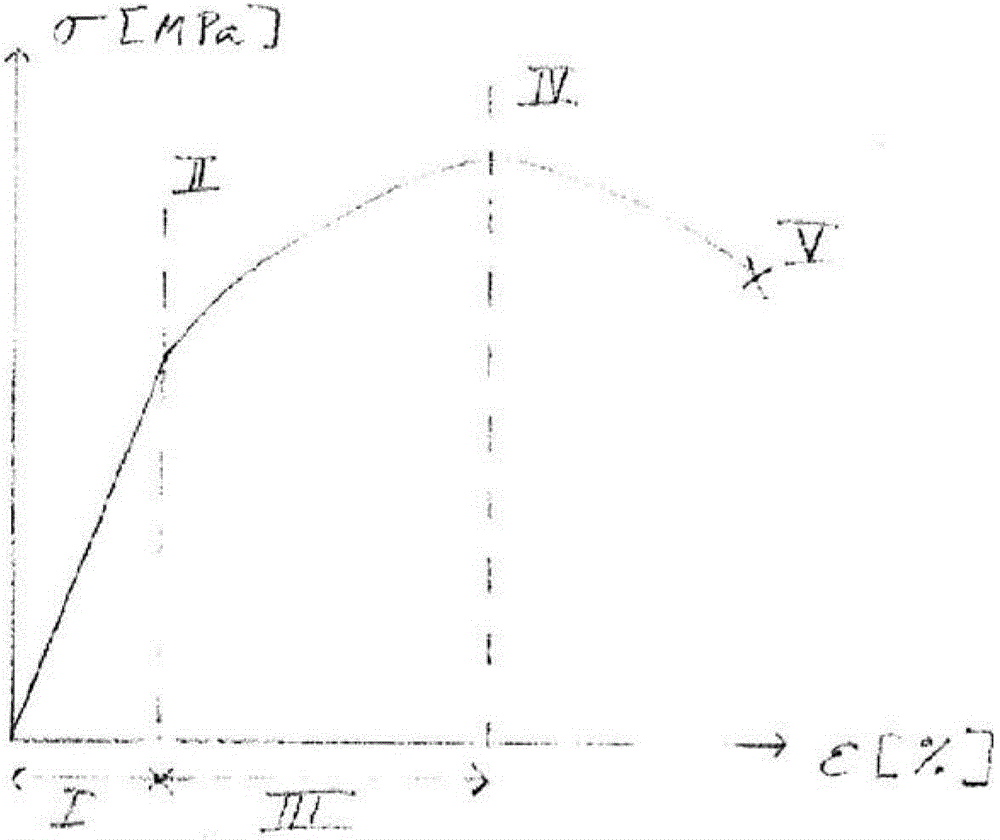

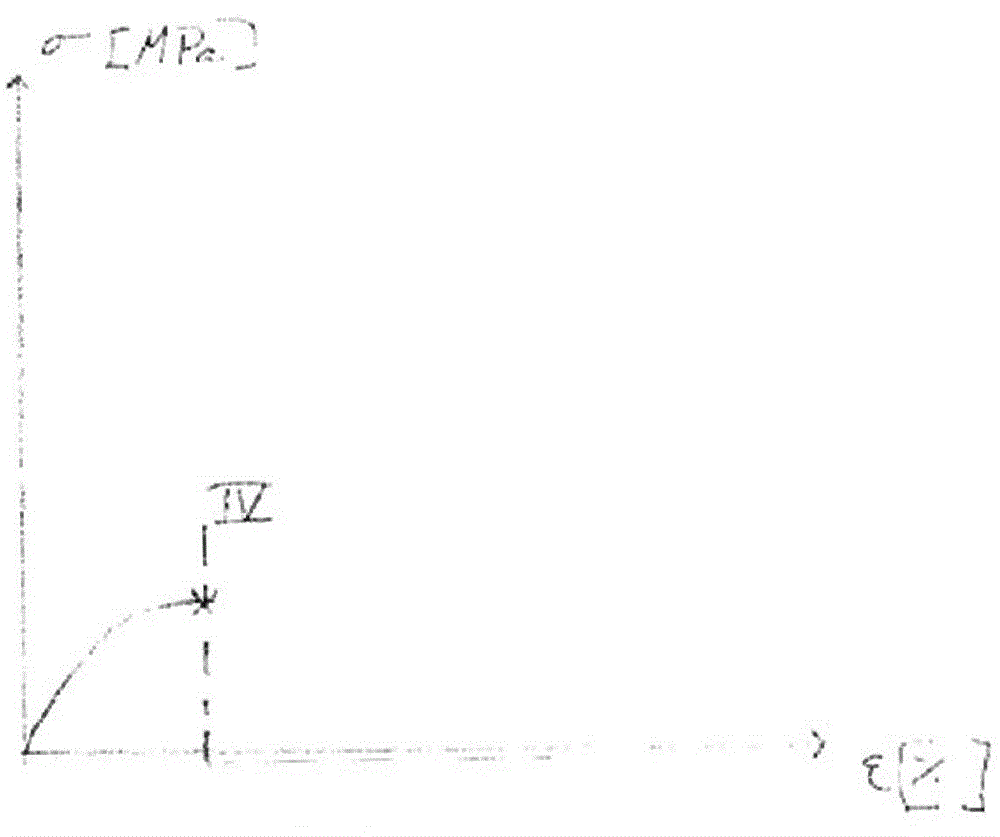

[0028] By way of introduction, the theoretical background of the invention will be referred to Figure 1a and 1b describe.

[0029] The strength of a metallic material can be represented, for example, by a stress-strain diagram based on a tensile test of a test bar. Figure 1a Schematically depicts the mode of a stress-strain diagram for a variety of metallic engineering materials, such as steel. Figure 1b The mode of the stress-strain diagram for gray iron is shown.

[0030] Figure 1a In general, a first region I is depicted in which lower forces act on the test rod. In said regions, the distance between the atoms in the material increases without affecting their mutual arrangement. If the force is removed, the test rod returns to its original dimensions. The test rod is thus elastically deformed. Said region is often referred to as the linear elastic region. If more force is applied to the test rod, the stress in the material increases. When the stress exceeds the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com