Quality inspection system based on cloud server

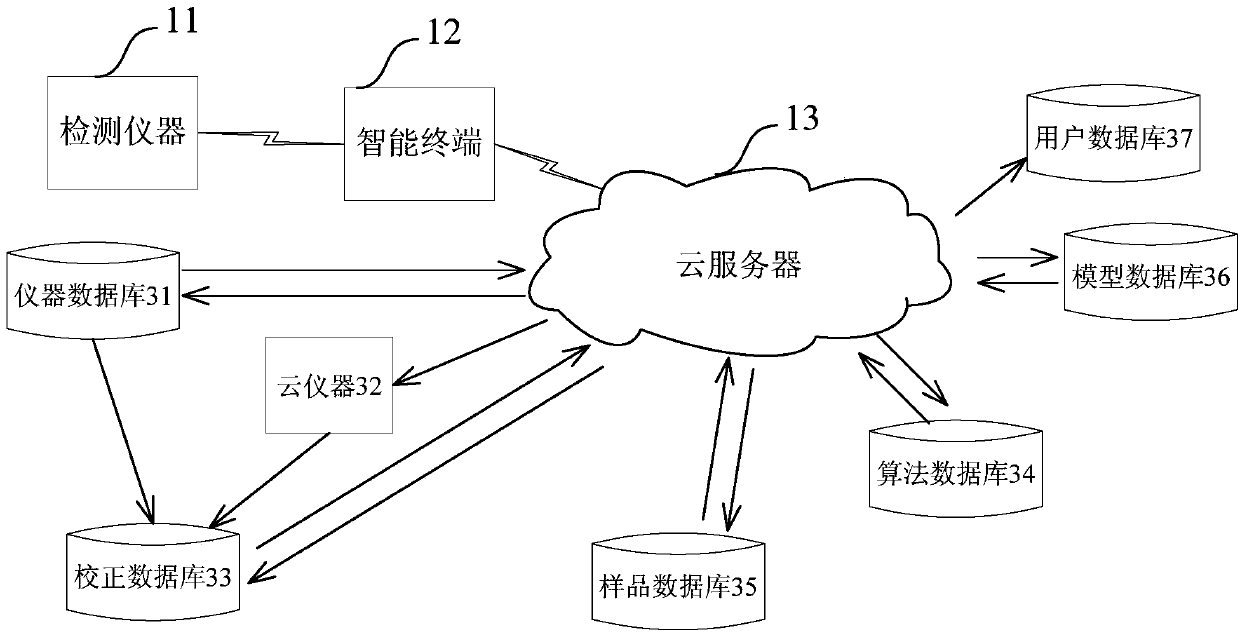

A cloud server and detection system technology, applied in the field of analytical instruments and the Internet, can solve problems such as waste of detection resources and inability to monitor quality more effectively, achieve simplification of networking, improve the efficiency and coverage of quality inspection, and speed up quality inspection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

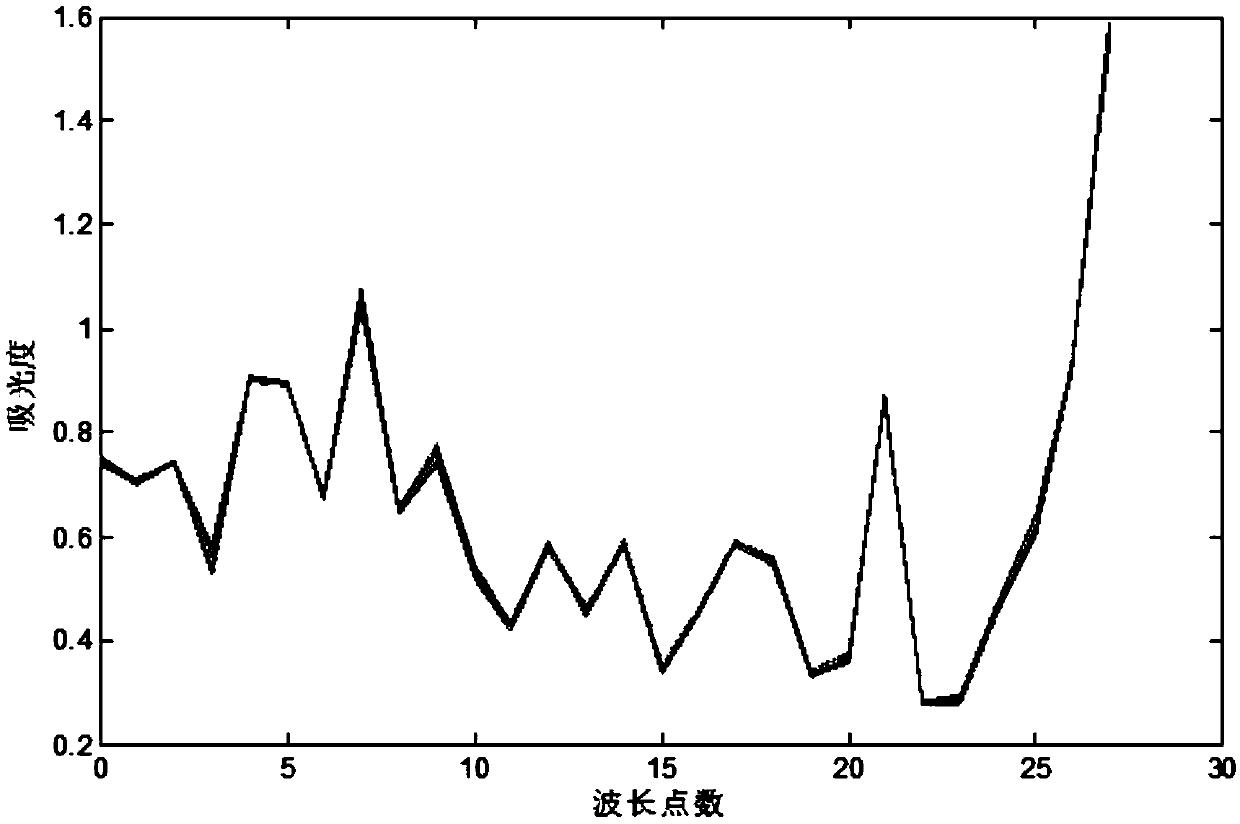

[0035] In this embodiment, a multi-source spectrometer is used as a detection instrument to detect the sample to be tested and collect corresponding data. The multi-source spectrometer is composed of LED light sources including 275 nm, 370 nm, 675 nm, 750 nm, 830 nm, 900 nm, 1100 nm, and 1500 nm, and the LED light sources are realized by photodiodes. As a sensor, the multi-source spectrometer is connected to the smart terminal with Bluetooth. The smart terminal is a mobile phone with an Android system. The mobile phone communicates with the cloud server through wifi. The cloud server uses Alibaba Cloud. The instrument database used is a mySQL format database. The instrument database contains the instrument serial number of the multi-source spectrometer (zlg1602030001) and detection The sample type (Ginkgo), the number of testing batches (10 batches), the testing time (2016.4.23), and the cumulative use time are in hours (10 hours). That is, the instrument with the serial numbe...

no. 2 example

[0043] The difference from the first embodiment is that the detection instrument is composed of 275nm, 285nm, 295nm, 330nm, 375nm, 420nm, 450nm, 600nm, 675nm, 830nm UV-visible LED light sources. Table 21 shows the data records of the second embodiment in the instrument database.

[0044] Table 21 Data information of the second embodiment recorded in the instrument database

[0045] serial number

Test sample

Batch number

Test date

Instrument cumulative test time (h)

zlg1604020012

Salvia

20

2016.5.7

3

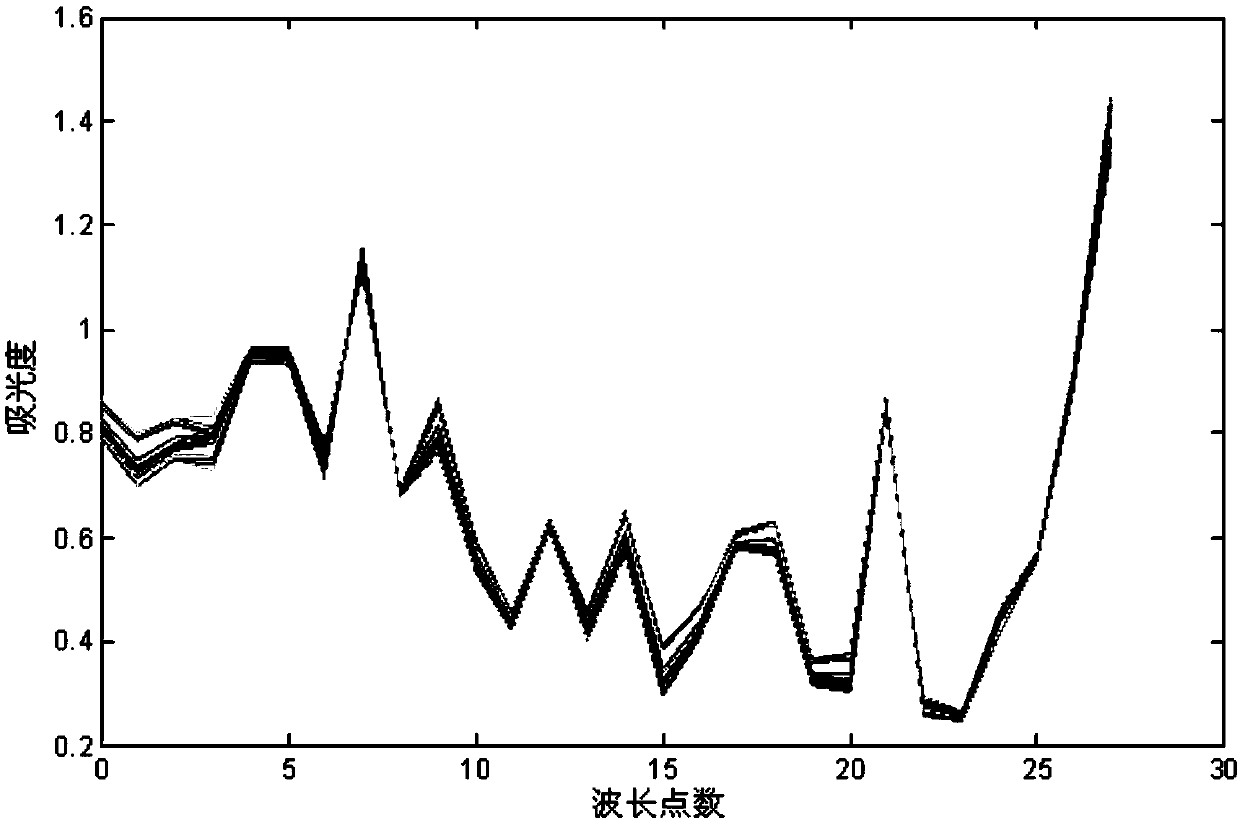

[0046] The composite spectra of 20 batches of Danshen samples according to the second embodiment of the present invention are as follows image 3 Shown. The calibration of the instrument signal is realized by the neural network algorithm, and the prediction model of the sample properties is established by the PLS algorithm. The predicted content of each component in 20 batches of Danshen is shown in Table 22. The data in Table 22 is sent to the smart terminal through the clo...

no. 3 example

[0051] The difference from the first embodiment is that the detection instrument adopts an ultraviolet spectrometer, the intelligent terminal adopts a notebook computer, and the data record of the third embodiment in the instrument database is shown in Table 31.

[0052] Table 31 Data information of the third embodiment recorded in the instrument database

[0053] serial number

Test sample

Batch number

Test date

Instrument cumulative detection time (h)

zlg1604030001

honeysuckle

3

2016.6.7

2

[0054] The ultraviolet spectra of the 3 batches of honeysuckle samples according to the third embodiment of the present invention are as follows Figure 4 Shown. The calibration of the instrument signal is simulated by logistic regression algorithm, and the prediction model is established by the random forest number algorithm. The predicted content of each component in the three batches of honeysuckle is shown in Table 32. The data in Table 32 is sent to the smart terminal through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com