An automatic precision laser welding method based on ccd visual detection

A visual inspection and precision welding technology, applied in the field of welding processing, can solve the problems of small photographic field of view, high detection accuracy, low detection accuracy, etc., and achieve the effect of satisfying high performance and huge development potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

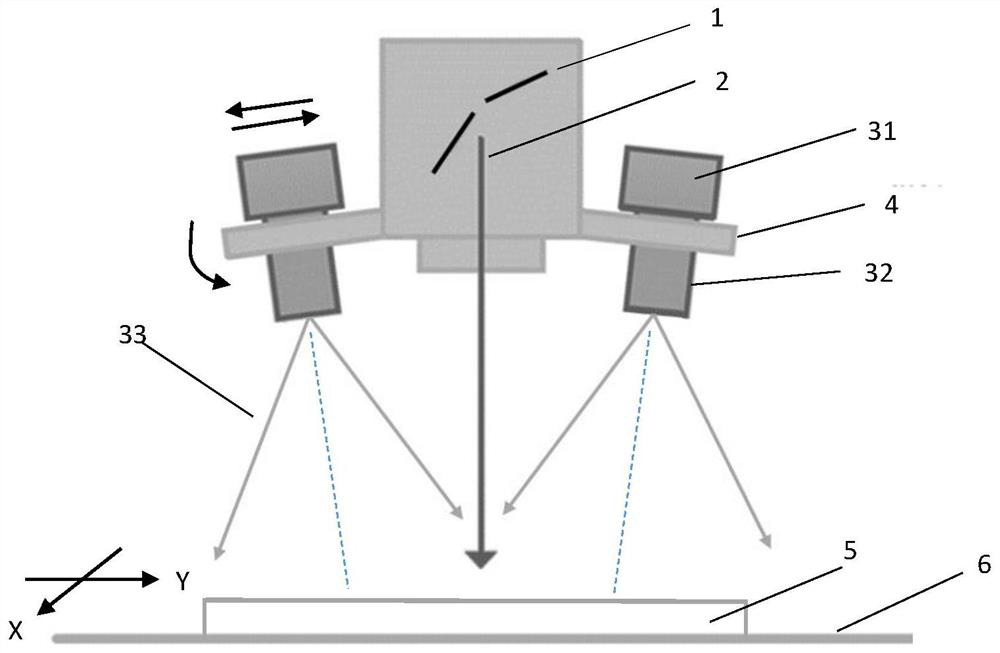

[0041] The principle of the method of visual inspection of laser welding parts based on CCD is as follows: figure 1 . The visual detection system is composed of CCD sensor, imaging objective lens, intelligent image processing software and auxiliary lighting, etc. It specifically includes multiple detectors composed of high-resolution CCD sensor 31 and imaging objective lens 32. The CCD sensor is equipped with corresponding objective lens according to the detection needs . There are two or four CCD detection devices, the field of view of four is larger, and the three-dimensional imaging is more accurate, but the cost is also higher. In this example, there are two detectors, which are respectively located on both sides of the light outlet of the dynamic focus scanning system 1, and the CCD detection system is fixed on the support frame 4 and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com