A quality inspection method for battery connectors based on machine vision

A quality inspection method and battery connector technology, applied in sorting and other directions, can solve the problems of limited application scope, slow speed and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

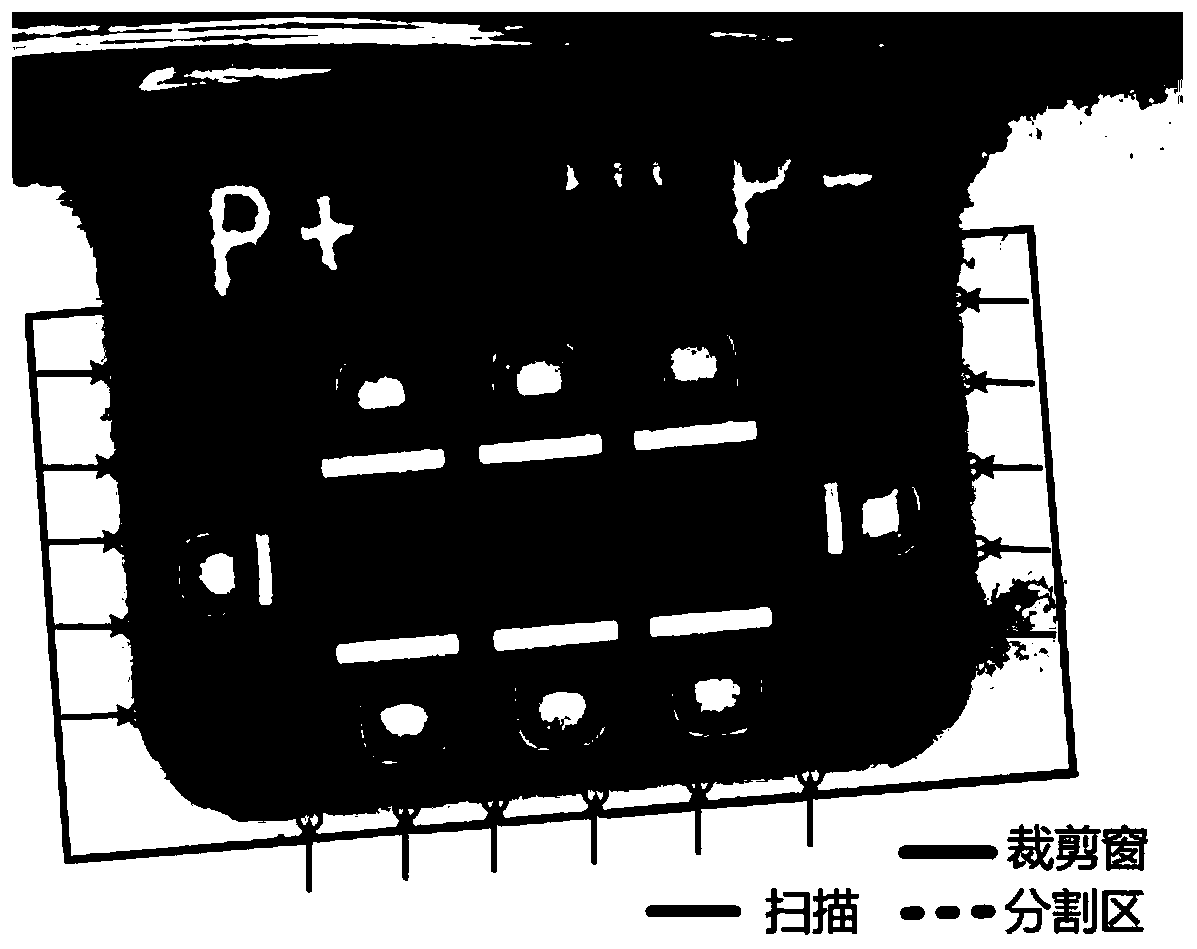

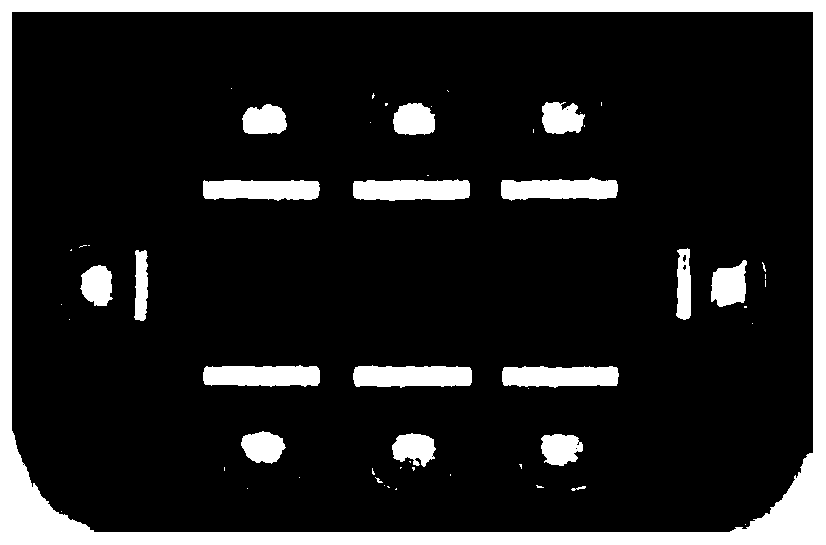

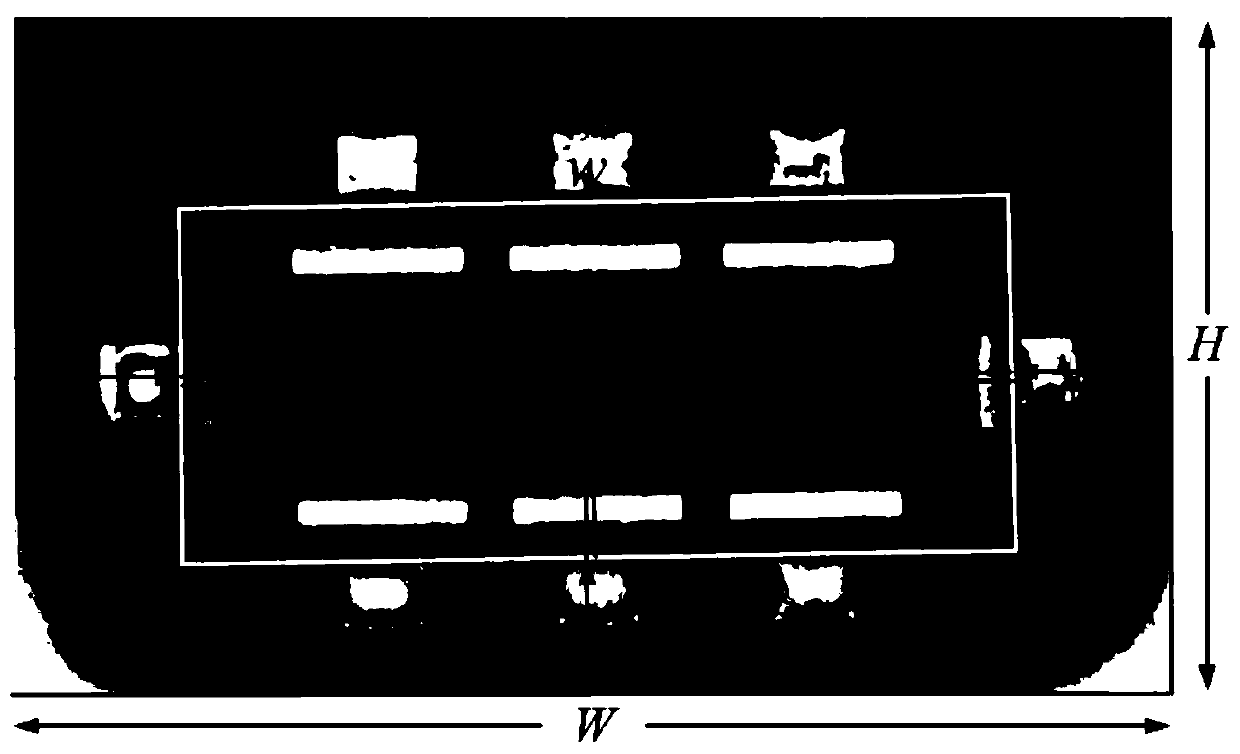

[0094] The invention provides a battery connector quality detection method based on machine vision. The premise of detection needs to collect the image of the detected connector, and it is assumed that the image of the detected connector has been obtained. Image preprocessing is required before various defect detection, which involves three links:

[0095] A1. Template dataset

[0096] The primary task before the connector quality inspection is to establish a connector template data set to prepare for the later connector positioning and inspection links. As the name suggests, the template is a standard and a reference, so it is necessary to capture an original image of the connector without defects and skew. In this image, the image M of the connector area is intercepted, and its feature value is extracted and saved, and marked in the form of ID to prepare for later template matching. At the same time, the width w and height h of the image of the connector area are calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com