Smashing device of dry food

A pulverizing device and food technology, which is applied to household machinery, household appliances, and applications for filtering food, can solve the problems of inconvenient material addition and pouring, electric shock injury to users, and easy scratching of users, etc., to improve convenience. Safety, increase safety, scientific and reliable effect of design principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

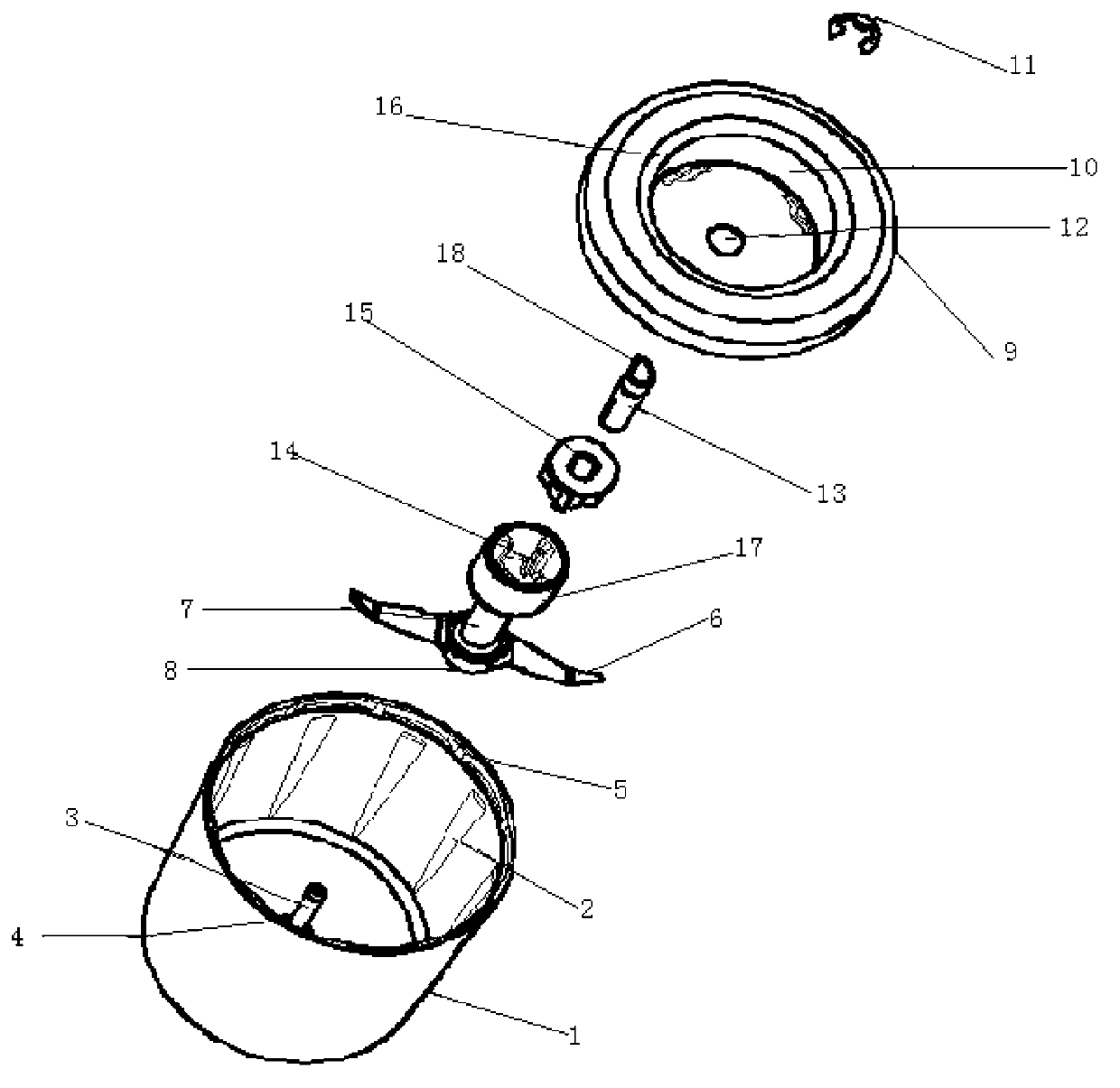

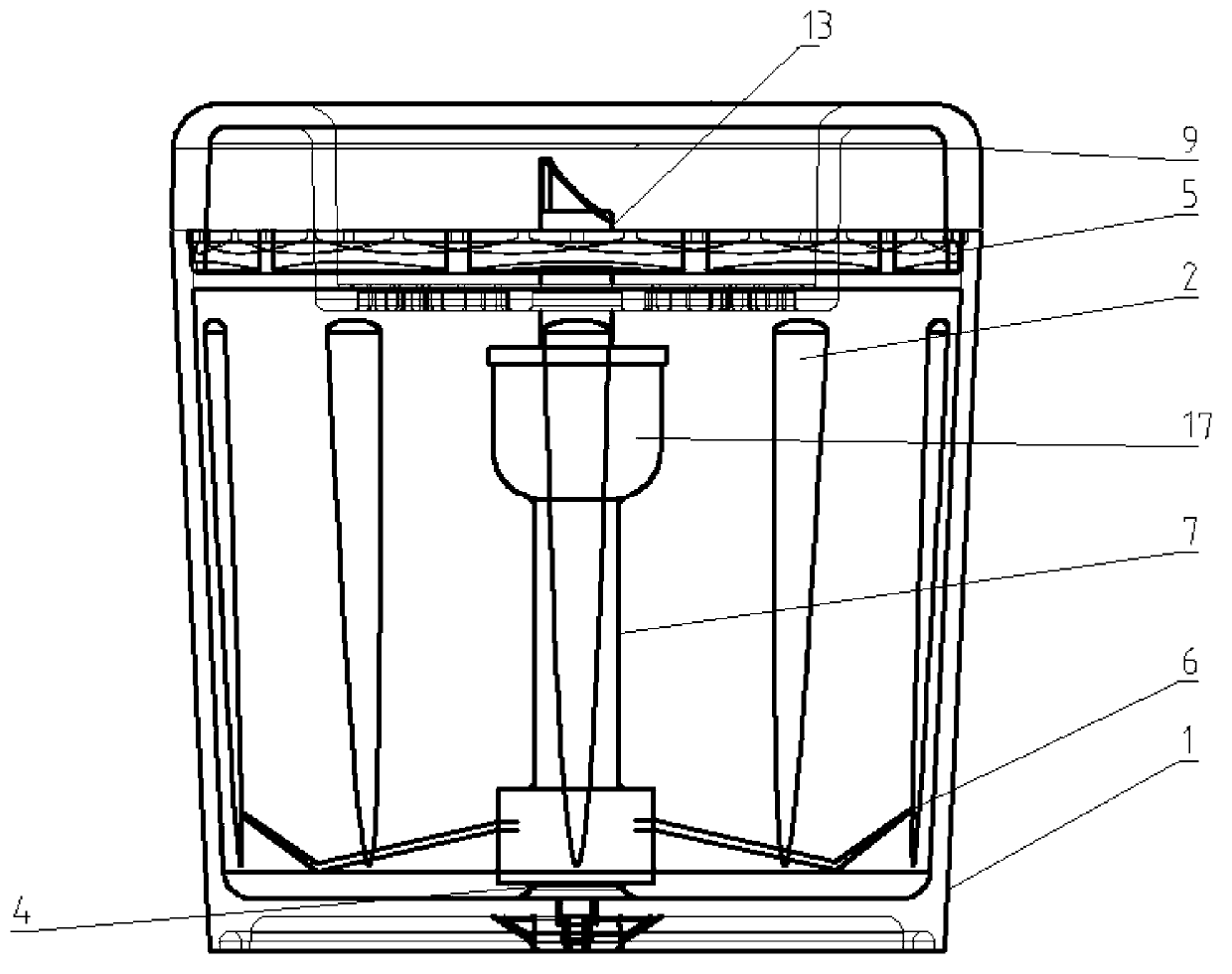

[0011] The main structure of this embodiment includes bottom box 1, groove 2, vertical shaft 3, fixed seat 4, card slot 5, rotary knife 6, rotating shaft 7, inner cavity 8, box cover 9, docking port 10, bayonet pin 11, transmission Mouth 12, transmission shaft 13, transmission groove 14, transmission card 15, docking groove 16, transmission cavity 17 and docking seat 18; 4 is fixed with a vertical shaft 3 with a columnar structure, and linear grooves 2 with upper width and lower width are evenly distributed on the side of the inner cavity wall of the bottom box 1; An integrated symmetrical fan-shaped rotary knife 6 is fixedly formed, and a circular open transmission chamber 17 is fixedly formed on the top of the rotating shaft 7. A transmission groove 14 is formed on the inner wall side of the transmission chamber 17, and a transmission card is embedded in the transmission chamber 17. 15. The transmission card 15 and the transmission groove 14 are meshed with each other to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com