Notched-bar microstructure-crack initiation method used for chipless fine blanking

A technology of precision blanking and microstructure, which is applied in the field of microstructure crack initiation of chipless precision blanking notched bar material, which can solve the problems that surface loading cannot be realized, and achieve the effect of shortening blanking time and improving blanking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

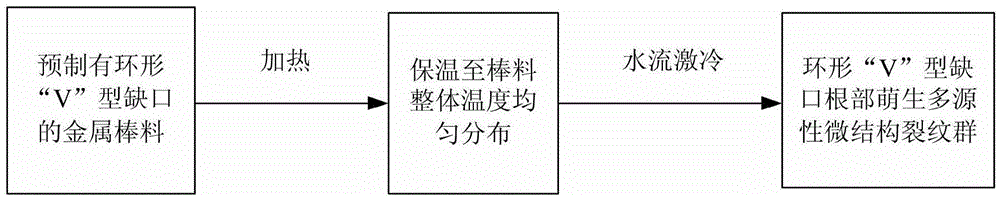

[0020] refer to figure 1 , a method for initiating cracks in the microstructure of notched bar stock for chipless precision blanking, the specific steps are:

[0021] Step 1. According to the properties of different metal bars 3, the metal bars 3 prefabricated with annular "V"-shaped gaps are placed in a resistance heating furnace as a whole;

[0022] Step 2. According to the different materials of the metal bar 3, after setting the heating rate of the resistance heating furnace at 5-30°C / s, the resistance heating furnace starts to heat the metal bar 3 after powering on;

[0023] Step 3: After the heating temperature of the metal bar 3 reaches 300-1000°C, stop heating and keep the metal bar 3 warm for 3 minutes;

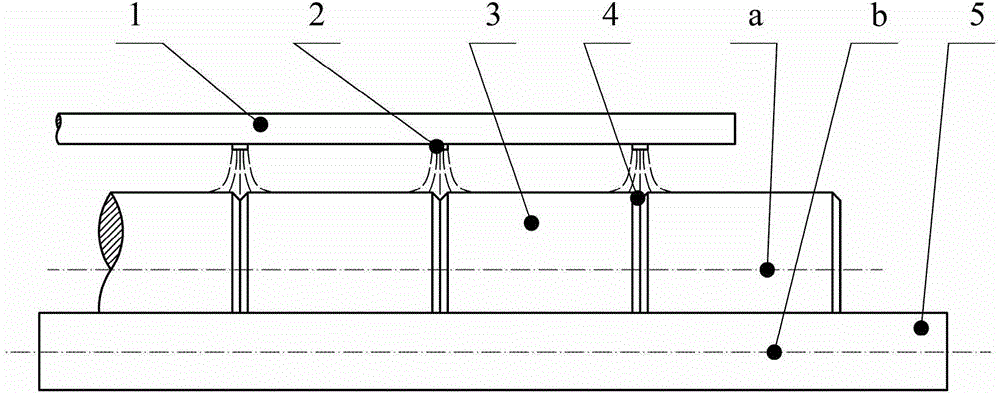

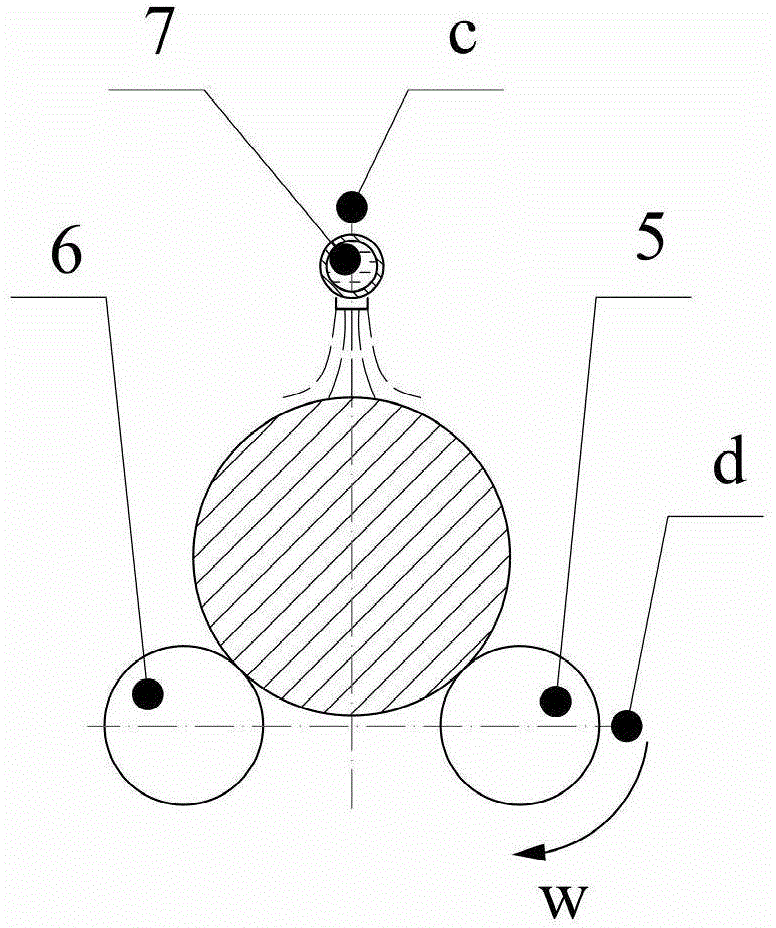

[0024] Step 4, moving the metal bar 3 from the resistance heating furnace to the bar chilling device and turning on the power of the bar chilling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com