Automatic forming machine of flexible graphite seal rings

An automatic forming machine and flexible graphite technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of poor sealing performance of sealing rings, high requirements, and high scrap rate of defective products. Achieve the effect of high production efficiency, diversified use and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

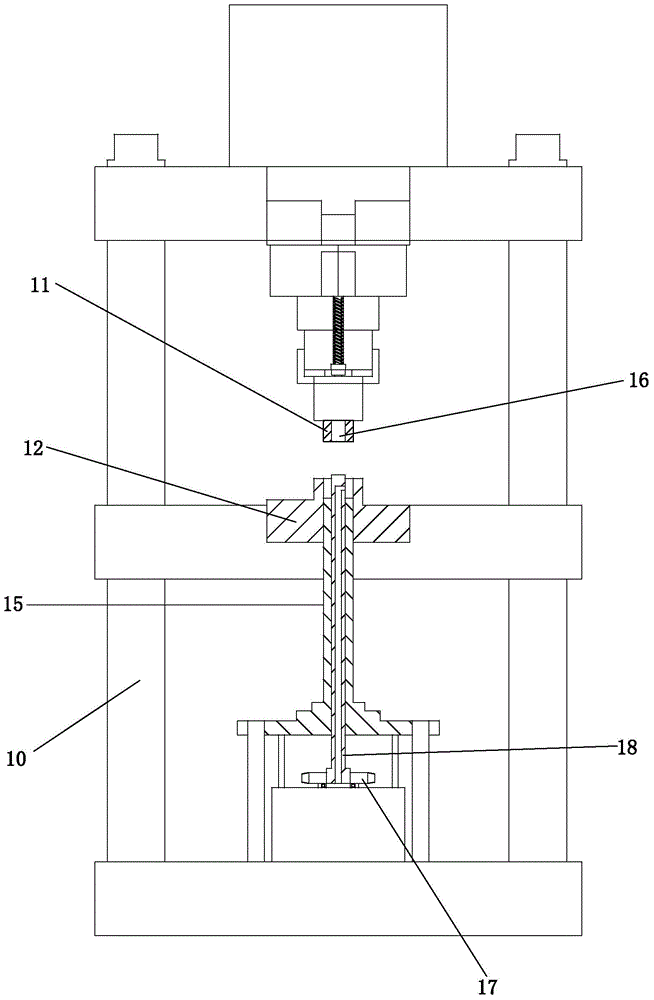

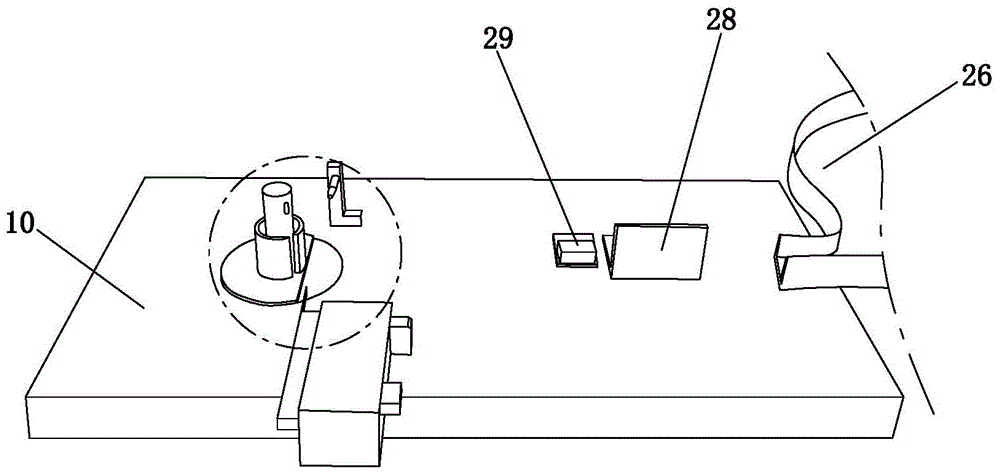

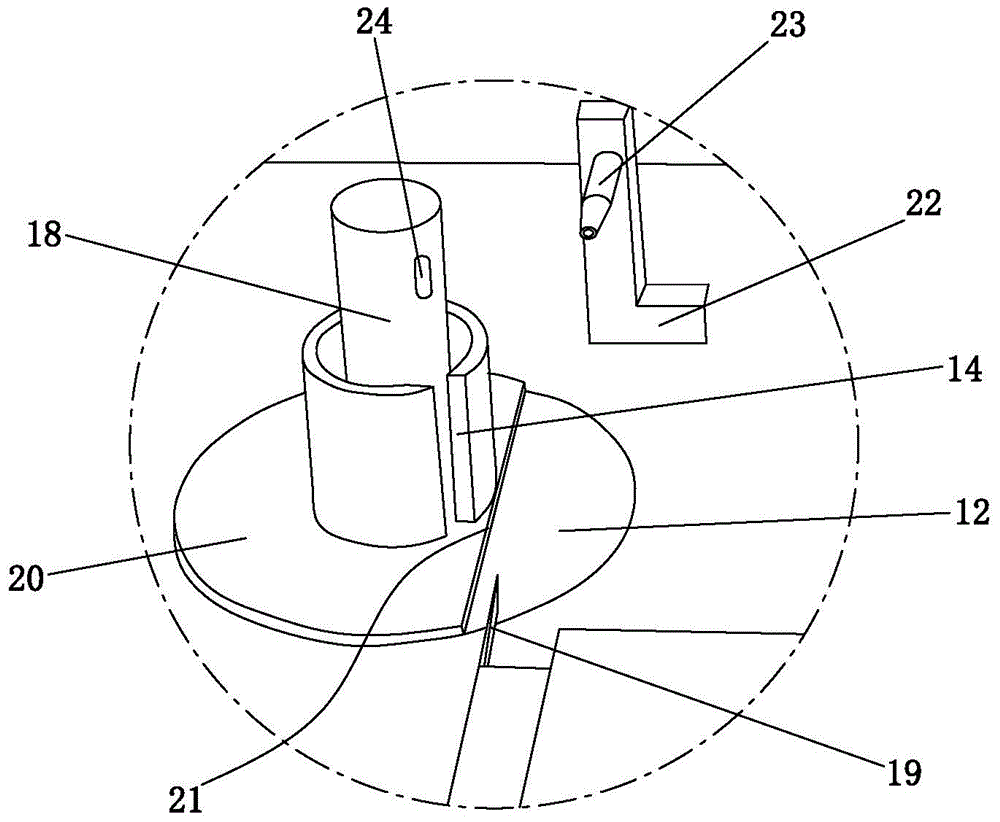

[0030] Such as Figure 1 to Figure 5 As shown, it is an automatic forming machine for a flexible graphite sealing ring disclosed by the present invention. The upper side of the frame 10 is provided with a punch 11 driven by a power device, and the middle part of the frame 10 is provided with a molding machine directly below the punch 11. Seat 12, forming seat 12 is provided with the through hole 13 that can punch into for punch 11 that runs through its upper and lower sides, the underside of frame 10 is provided with upper end stretches in the through hole 13 of forming seat 12 and is powered by power unit. Driven material transfer and ejector device, the forming seat 12 is provided with a feed port 14 communicating with the through hole 13 .

[0031] refer to figure 1 , 4 The material transfer and ejecting device includes an ejector rod 15 which is arranged on the lower side of the frame 10 and whose upper end extends into the through hole 13 and is driven by a power device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com