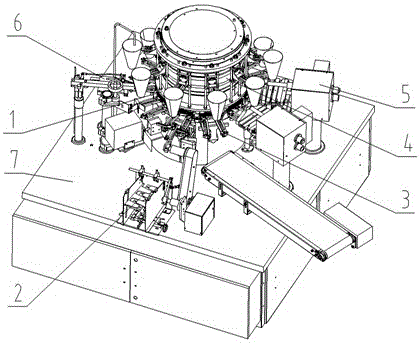

Ten-station continuous filling and packaging machine

A packaging machine, ten-station technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of slow packaging machine speed and great influence of packaging speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

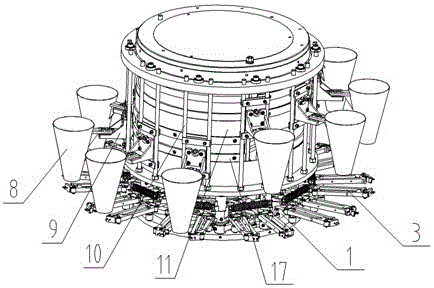

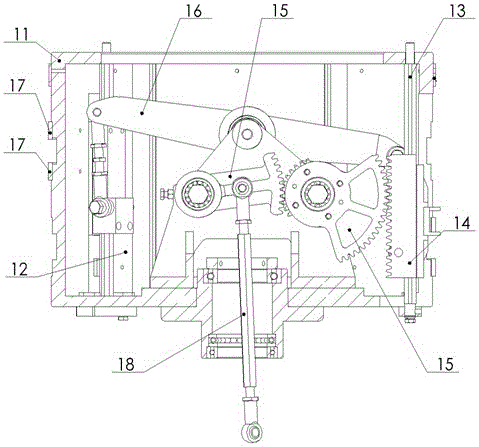

[0015] refer to Figure 1-Figure 5 , the ten-station continuous filling and packaging machine of the present embodiment includes a workbench 7, a rotating large plate 1, a bag loading device 2, a bag clamping device 3, a blanking device 4, a sealing device 5 and a bag opening and blowing device 6, The blanking device 4 includes a blanking hopper 8, a blanking fixed seat 9, a limit guide rod 10 for the blanking fixed seat, a rotating cylinder 11, a lifting block 12, a lifting guide rod 13, a lifting rack 14, and a special-shaped transmission gear 15 , lifting and swinging rocker 16, rotary track 17 and transmission pull rod 18, said blanking hopper 8 is fixed on the blanking fixed seat 9 respectively, and the blanking fixed seat 9 is respectively fixed on the limit guide rod 10 of the blanking fixed seat, and the falling The material fixing seat limit guide rod 10 is fixed on the rotating large plate 1; the sealing device 5 includes a sealing square box 19, a sealing cylinder 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com