Angle material for wall surface decoration, manufacturing method of angle material

A corner material and wall surface technology, which is applied in the corner material and its manufacturing field for wall surface decoration, can solve the problems of dry corners, offset position of wall cloth material paste, poor paste, etc., and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment

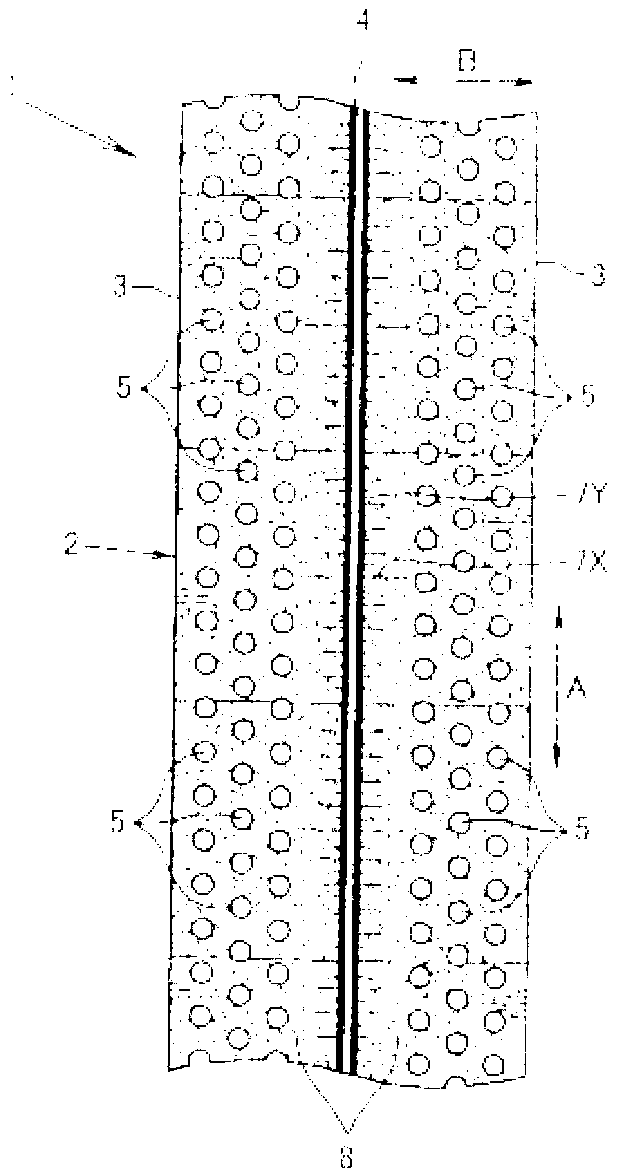

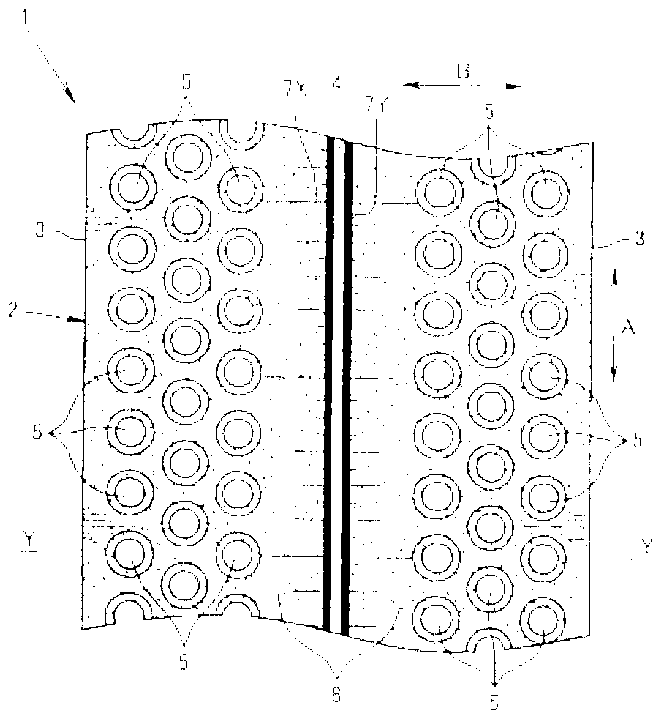

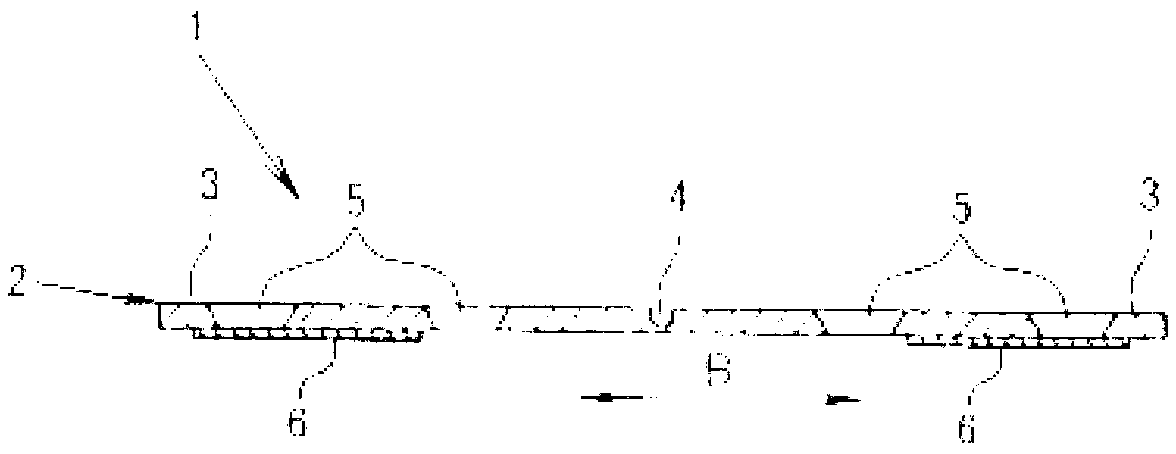

[0201] Next, use Figure 10 , after the folding lines 4 are set on the inner and outer sides of the plastic sheet 2, the corner material 1 for wall surface decoration of the second embodiment is described.

[0202] Figure 10 It is an explanatory view of the structure of the wall surface finishing trim 1 of the second embodiment, and is an end cross-sectional view of the wall surface finishing trim 1 after the folding line 4 is provided on the inner and outer sides.

[0203] In the second embodiment, parts belonging to the same configuration as those in the first embodiment are denoted by the same symbols, and detailed description thereof will be omitted here.

[0204] If the folding line 4 of the described embodiment is only arranged on the surface of the plastic sheet 2, although it can be folded flexibly to the inside and outside of the corner material 1 for wall surface decoration, as shown in FIG. Figure 10 As shown, if the folding line 4 of the same composition is arr...

no. 3 Embodiment

[0212] Next, using FIG. 12 , a description will be given of the corner trim 1 for wall surface decoration of the third embodiment in which the concave dent portion 4f is provided on the back side of the plastic sheet 2 corresponding to the thinner portion of the folding line 4 .

[0213] Fig. 12 is an explanatory view of the structure of the corner material 1 for wall surface decoration of the third embodiment, Fig. 12(a) is a central cross-sectional view of the folding line 4 provided with a dent 4f, and Fig. 12(b) is provided with ( a) Cross-sectional view along line X3-X3 of the fold line 4 of the indentation 4f shown in a).

[0214] In the third embodiment, parts belonging to the same configuration as those in the first embodiment are denoted by the same symbols, and detailed description thereof is omitted here.

[0215] The formation process of the above-mentioned indented portion 4f is as follows: when the folding line 4 is set, the plastic sheet 2 is pressed in the thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com