Method for simulating roadway rock burst based on coaction of static load and blast load

A technology of joint action and rock burst, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the hidden dangers of normal operation of mine safety production projects, cannot fully simulate the mechanism of rock burst, Insufficient understanding of rock burst mechanism and other issues, to achieve the effect of reducing safety production risks, reducing damage, and avoiding injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and example the present invention will be further described:

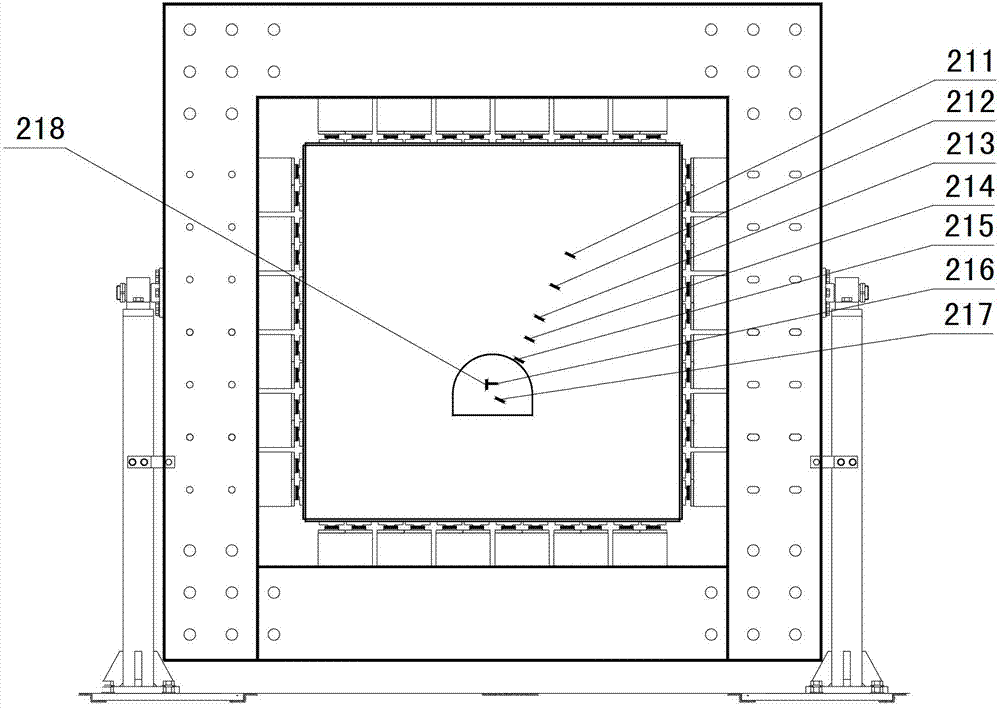

[0030] Low grade cement mortar is selected as the simulation material, the sand is medium sand, and the cement grade is P.O.32.5. The weight ratio of materials is: cement: sand: water = 1: 20: 1.5. Its 28-day uniaxial compressive strength is about 1.9MPa, elastic modulus is 380MPa, and tensile strength is 0.27MPa. In the embodiment, massive rock mass is simulated (the size of the block in the model body is about 2 cm). When ramming the model body, within the range around the cavern (0.8m in width and 0.7m in height), make blocks. The size of the block is about 2.0×2.0×4.0cm (length×width×thickness). It is at an angle of 45 degrees to simulate the massive rock mass around the cave; outside this range, no block processing is performed.

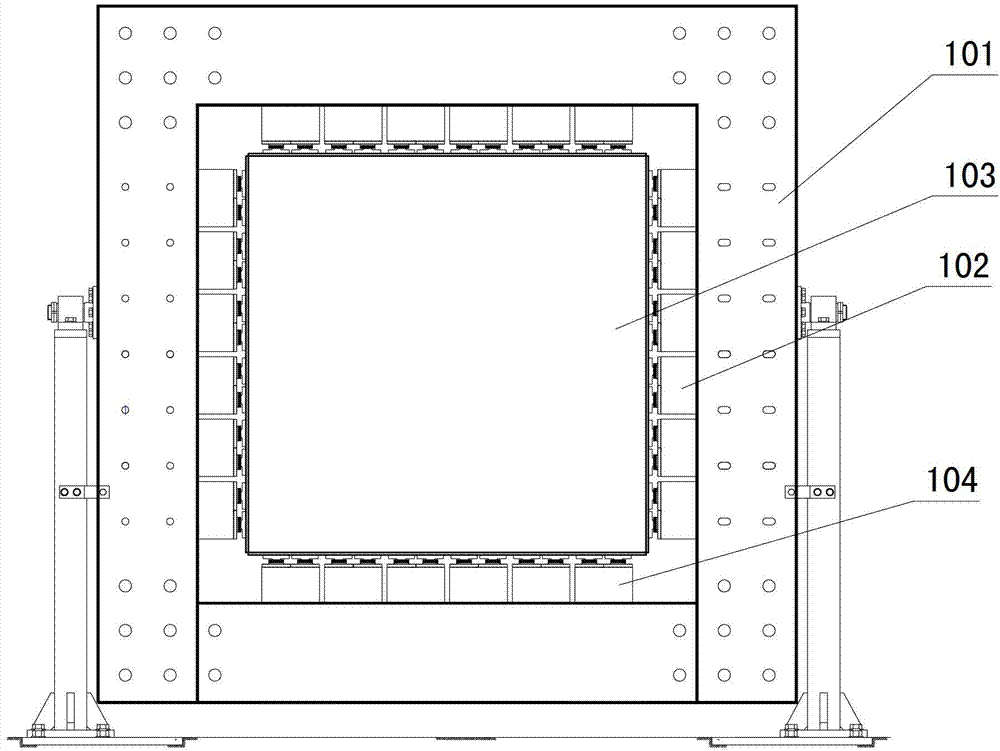

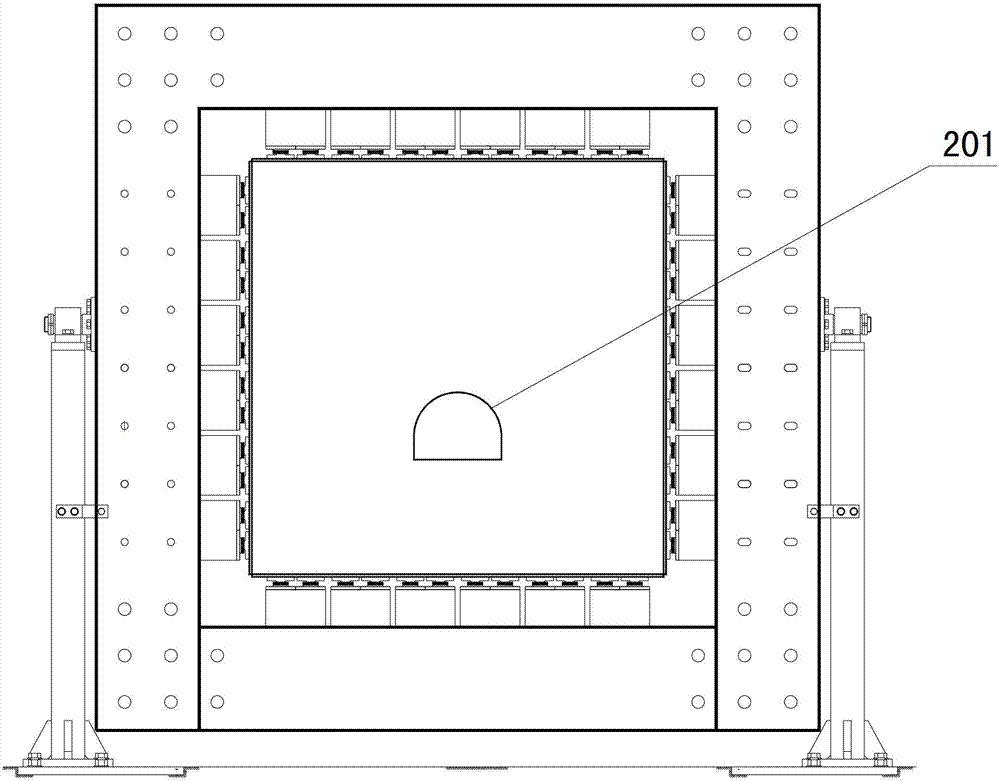

[0031] Such as figure 1 , figure 2 As shown, the test equipment is "YDM-D Geotechnical Engineering Structural Model Test S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com