Vehicle wheel

A wheel and rim technology, applied in the direction of wheels, spoked wheels, wheel cover discs, etc., can solve the problems of high mechanical load, unsatisfactory effect, superimposed centripetal acceleration or vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

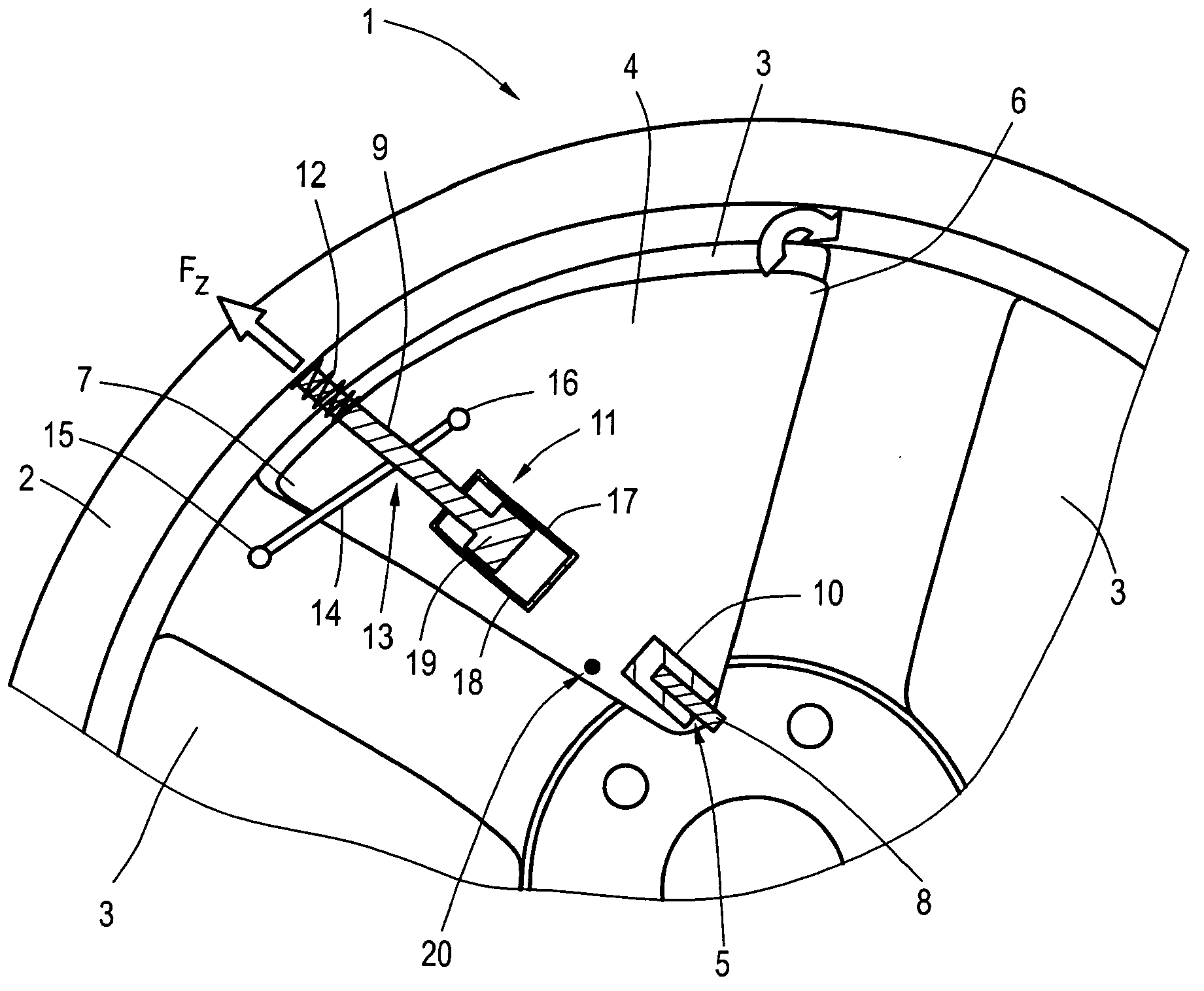

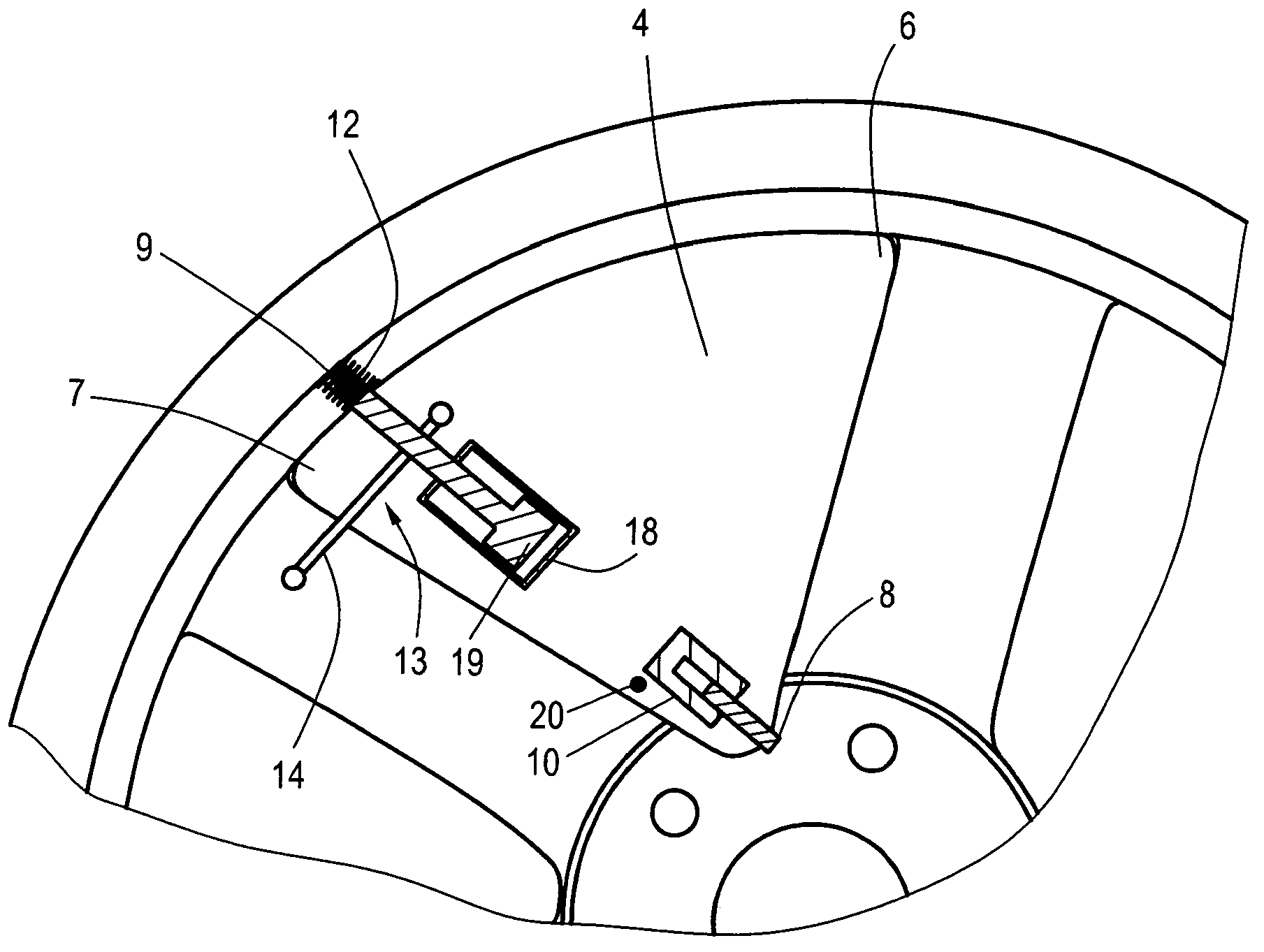

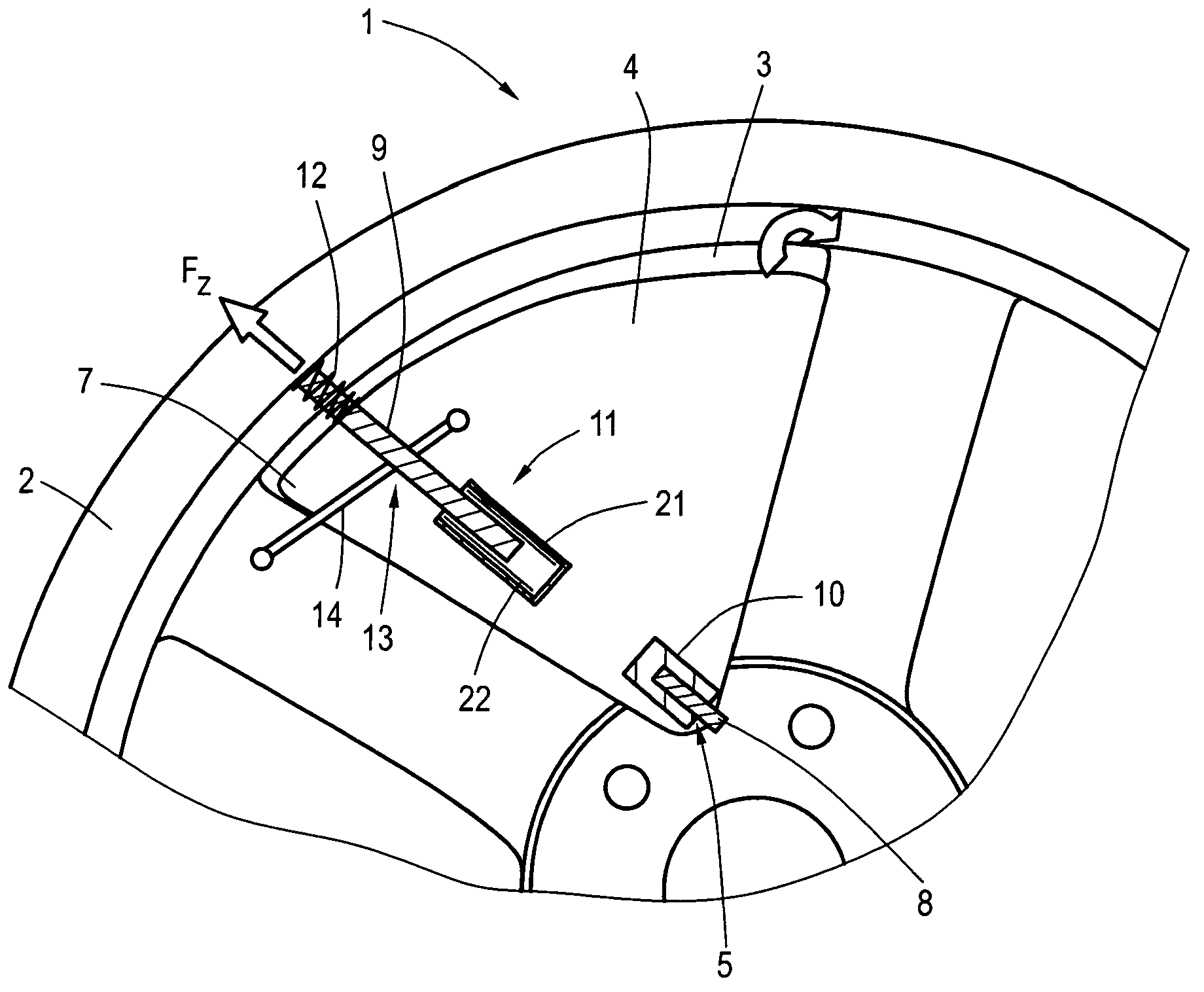

[0023] figure 1Shows a view of a part of a wheel 1 according to the invention including a rim 2 on which (not shown in detail here) a brake disc hub / brake hub is usually fastened or assigned in the assembled state. The rotor cover and the brake disc fixed on the brake disc hub. The rim 2 has a plurality of openings 3 for ventilation and appearance, for which in the example shown a sheet-like cover 4 is assigned in each case, wherein figure 1 Only one such cover 4 is shown in FIG. The cover 4 serves to close the corresponding opening 3 over a large area and to open it for ventilation if required.

[0024] To this end, the cover part 4 can be swiveled through a certain angle, for example 5° to 10°, about the pivot axis 5 . according to figure 1 and 2 The view in is related to the inside view of the rim 2. The swing mobility of each cover around the swing axis 5 is such that each cover 4 is figure 1 The right-centre outer corner 6 is angled towards the inside of the rim, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com