a fertilizer machine

A fertilizer mixing machine and frame technology, applied in mixers, mixer accessories, mixers with rotating mixing devices, etc., can solve the problems of unstable operation, increased floor space, height, etc., to reduce process control points, Ensure stable operation and avoid error-prone effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

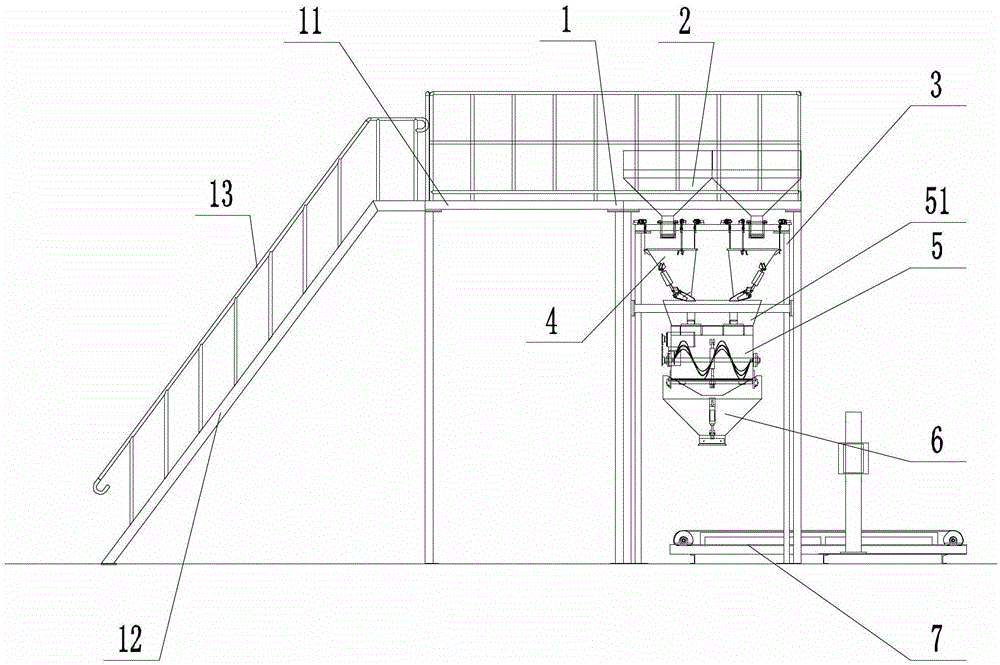

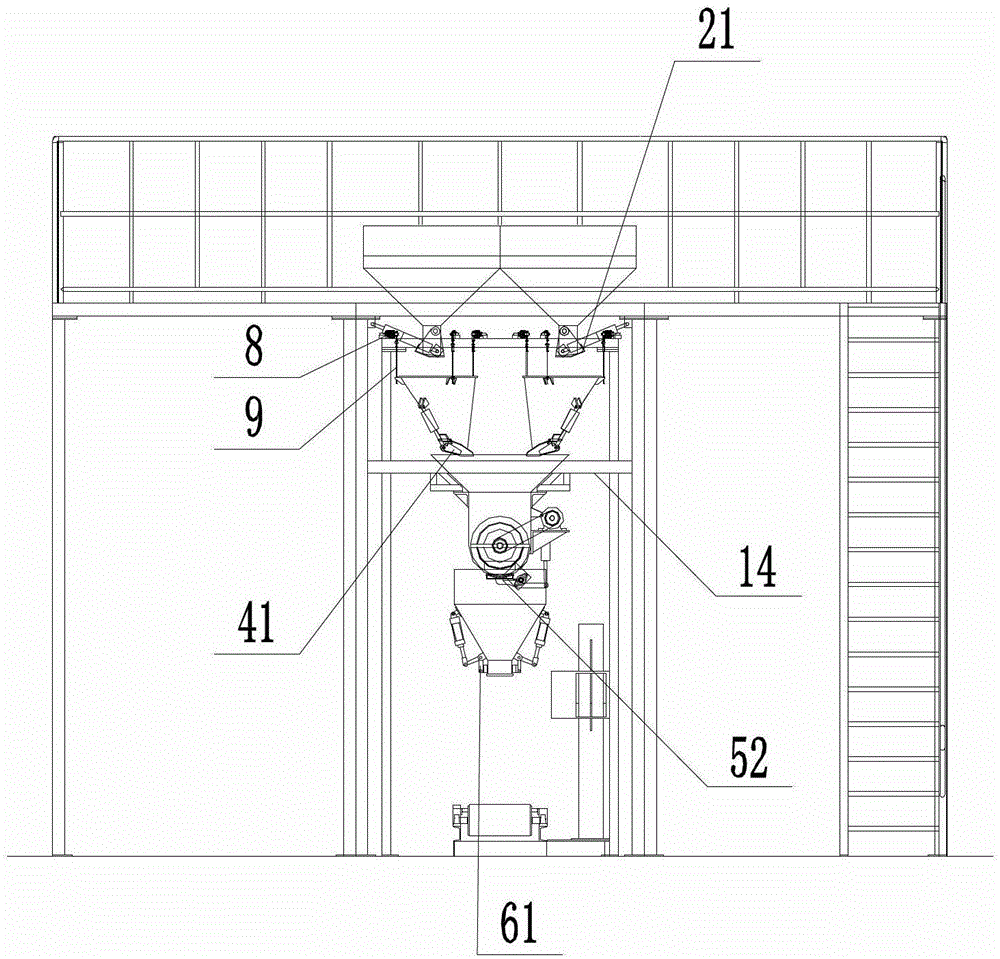

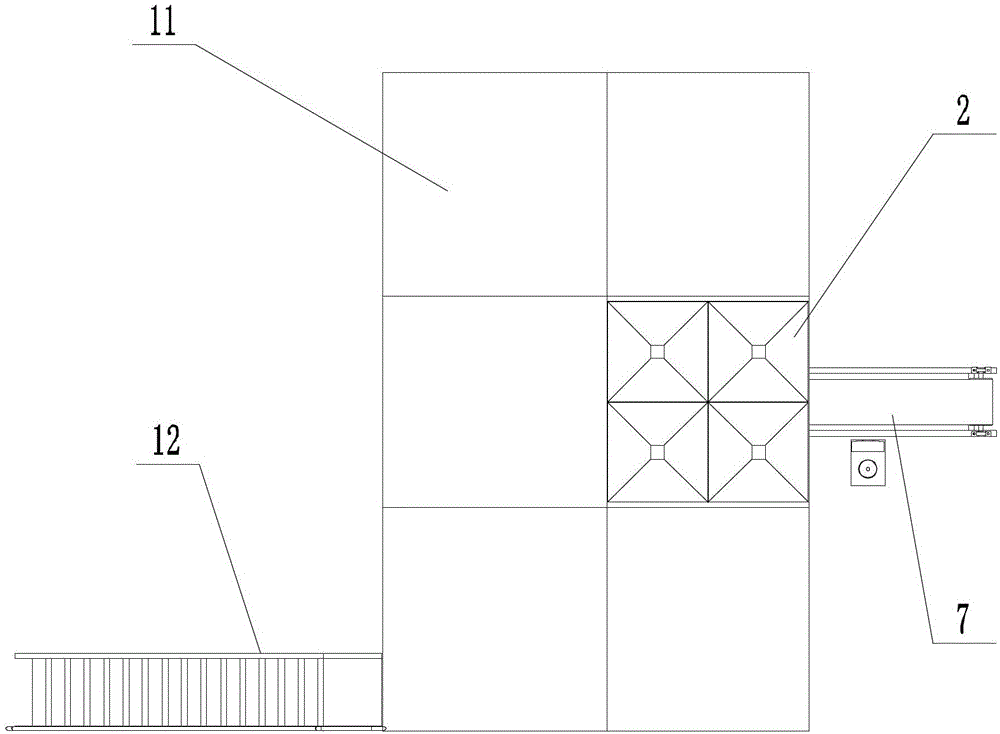

[0017] Examples of the present invention are Figures 1 to 3 As shown, it includes a detachable first frame 1, so when the fertilizer distribution machine needs to be transported, only the first frame 1 needs to be disassembled, and the whole fertilizer distribution machine can be divided into multiple parts that are easy to carry , to avoid the problem that the fertilizer dispensing machine needs to be transported as a whole in the past. After the components of the fertilizer distributing machine are delivered to the destination, the components of the first frame 1 can be connected to each other through bolts, so that the first frame 1 can be reassembled and used; The top of the first frame 1 is provided with a platform 11 for the user to stand and observe the working state of the fertilizer dispenser or to place fertilizers, etc., one side of the platform 11 is provided with a staircase 12 extending to the bottom of the first frame 1, the platform 11 and the stairs 12 are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com