Multi-level rotatable polyester device used for ultrashort thin and soft fiber polyester spinning

A poly-fleece spinning and soft technology, which is applied in the field of multi-stage rotatable poly-pile devices, can solve the problems of inability to obtain ultra-short, fine and soft fibers with high blending ratio, high cost, and difficult process, and achieves simple structure, easy operation, The effect of saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

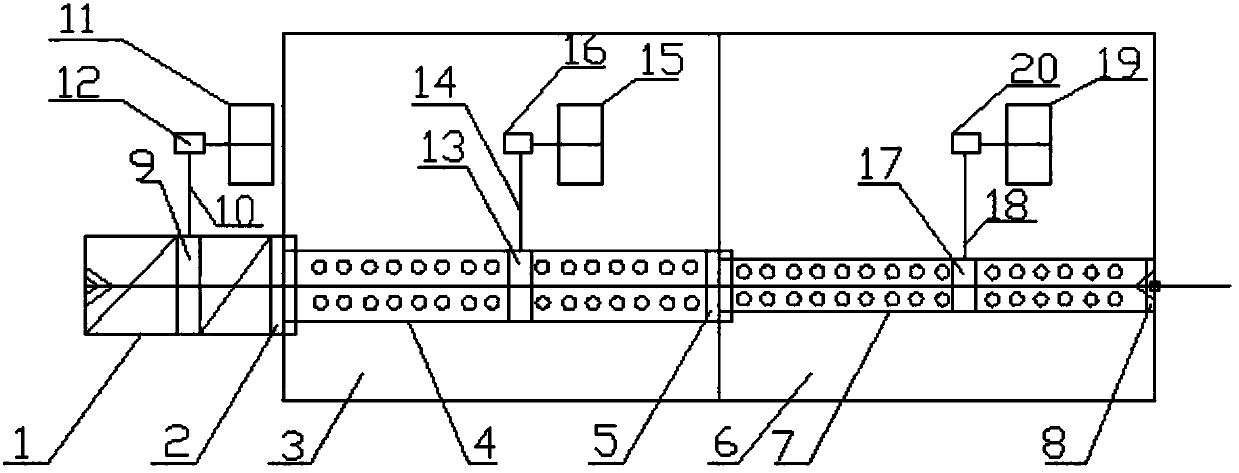

[0017] A multi-stage rotatable fleece gathering device for ultra-short and soft fiber fleece spinning, which is characterized in that it includes a first fleece gathering tube 1, one end of the first pile gathering tube 1 is connected to a first fixed rotating shaft 2, and the first fixed rotating shaft 2. Fixed on one side of the first negative pressure chamber 3 and connected to one end of the second fleece gathering tube 4, the other end of the second fleece gathering tube 4 is connected to the second fixed rotating shaft 5, and the second fixed rotating shaft 5 is fixed on the first The middle public part of the negative pressure chamber 3 and the second negative pressure chamber 6 is connected with one end of the third fleece gathering tube 7, and the other end of the third fleece gathering tube 7 is connected with the third fixed rotating shaft 8, and the third fixed rotating shaft 8 is fixed On one side of the second negative pressure chamber 6;

[0018] The first trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com