Method for producing phosphoric acid by hemihydrate technique

A technology of phosphoric acid and process, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problem of unfavorable phosphate rock fully reacting calcium sulfate hemihydrate crystal growth, inconvenient transportation and recycling of phosphogypsum, filtration separation and Poor washing effect and other problems, to achieve the effect of convenient semi-water reaction temperature, simplified and stable operation control, and stable semi-water reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

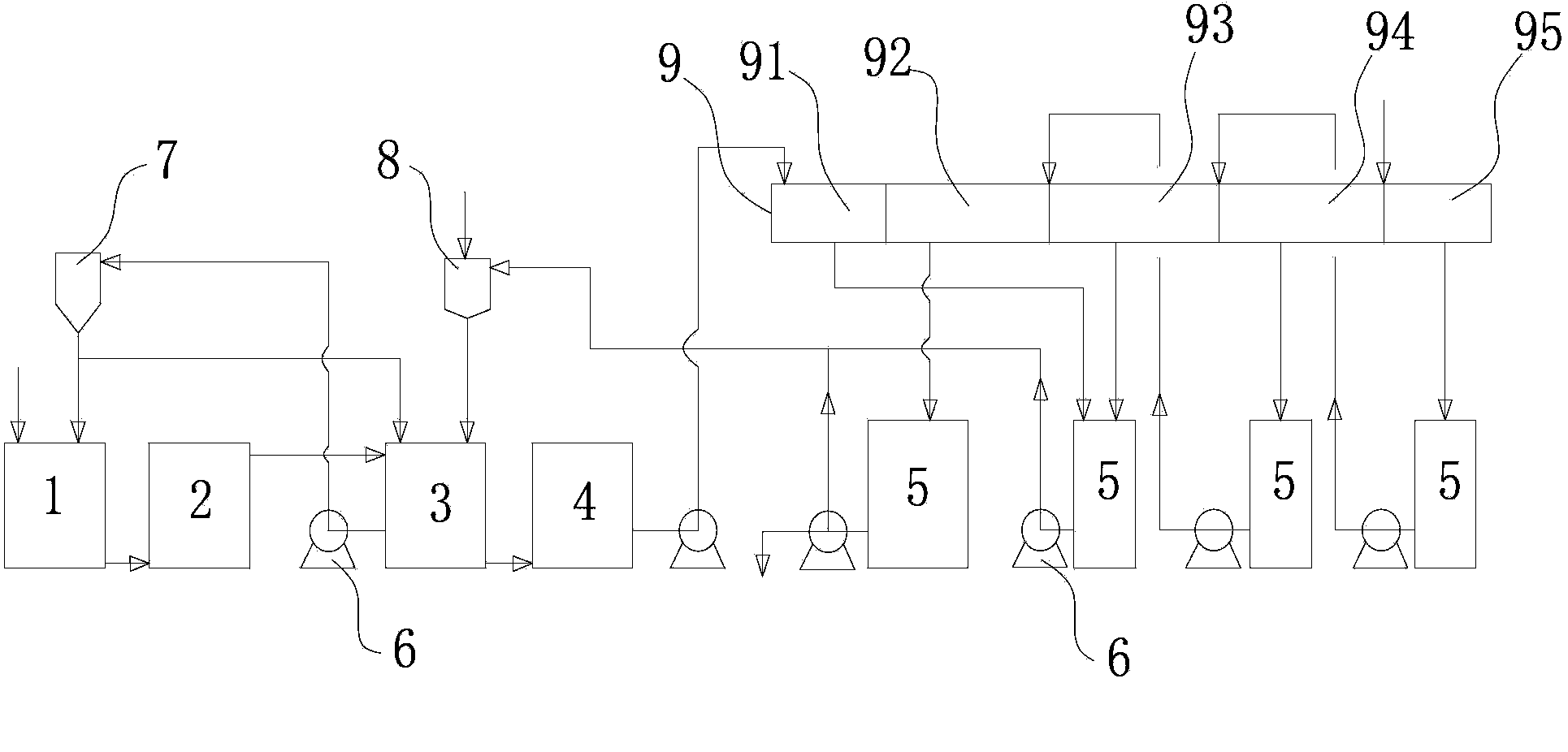

[0061] The method is carried out in the following steps: premixing of phosphate rock and slurry return, decomposition of phosphate rock, crystallization and slurry return, crystal growth, filtration and washing, and acid return.

[0062] The indicators of phosphate rock for production are as follows:

[0063] P 2 o 5 %

CaO%

MgO%

h 2 O%

Fe 2 o 3

Al 2 o 3

Acid insoluble %

33.05

48.21

0.76

12.97

0.46

0.47

5.6

[0064] 1. Phosphate rock is premixed with the return slurry from the crystallization tank 3

[0065] The phosphate rock powder feeds continuously at 80t / h into the premixing tank 1, and the slurry from the crystallization tank 3 cooled by the flash evaporator 7 feeds at 1000m 3 Enter in / h, premix and react in premix tank 1, the reaction temperature is 90°C, and the indicators in the premix tank are as follows:

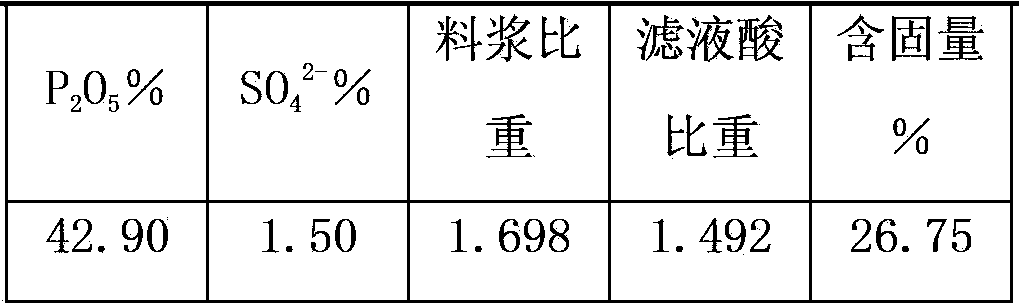

[0066]

[0067] The return index is as follows:

[0068] ...

Embodiment 2

[0078] The method is carried out in the following steps: premixing of phosphate rock and slurry return, decomposition of phosphate rock, crystallization and slurry return, crystal growth, filtration and washing, and acid return.

[0079] The indicators of phosphate rock for production are as follows:

[0080] P 2 o 5 %

CaO%

MgO%

h 2 O%

Fe 2 o 3

Al 2 o 3

Acid insoluble %

32.5

47.6

1.40

13.4

0.8

0.5

5.4

[0081] 1. Premixing of phosphate rock and return slurry

[0082] Phosphate rock powder feed rate is 85t / h, 1150m 3 The amount of pulp return per hour is pre-reacted in the premixing tank 1, the reaction temperature is 95°C, and the indicators in the premixing tank 1 are as follows:

[0083] P 2 o 5 %

CaO%

slurry ratio

filtrate acid

Solid content

[0084]

Heavy

%

43.35

1.01

1.76...

example 3

[0096] The method is carried out in the following steps: premixing of phosphate rock and slurry return, decomposition of phosphate rock, crystallization and slurry return, crystal growth, filtration and washing, and acid return.

[0097] The indicators of phosphate rock for production are as follows:

[0098] P 2 o 5 %

CaO%

MgO%

h 2 O%

Fe 2 o 3

Al 2 o 3

Acid insoluble %

34.36

48.23

1.17

12.95

0.46

0.81

6.4

[0099] 1. The amount of phosphate rock powder is 78t / h, 1000m 3 The amount of slurry returned per hour is pre-reacted in the premixing tank 1, the reaction temperature is 97°C, and the indicators in the premixing tank 1 are as follows:

[0100]

[0101] The return index is as follows:

[0102]

[0103] 2. Decomposition of phosphate rock

[0104] The semi-aqueous slurry overflows to the decomposition tank 2 for further decomposition reaction, and the reaction temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com