Method for manufacturing viscose through ultrasonic polymerization reduction of bamboo and cotton composite pulp

A technology of compounding pulp and viscose fiber, which is applied in the field of viscose fiber manufacturing, can solve problems such as unstable product quality, large area of reaction kettle, and uneven reduction of polymerization, so as to reduce process control points and prevent uneven reaction. The effect of uniformity and reducing the difficulty of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

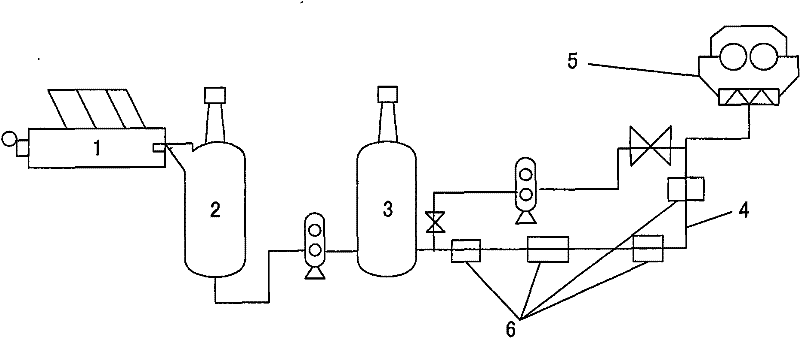

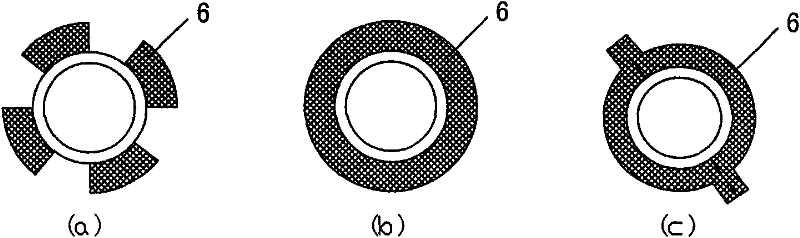

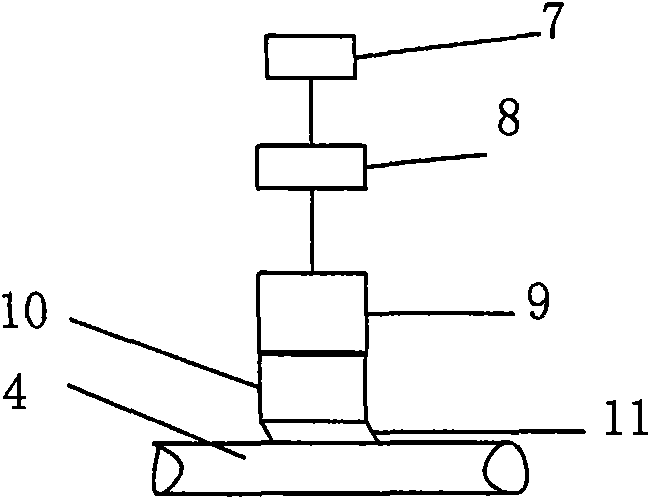

Method used

Image

Examples

Embodiment 1

[0046] The specific process steps are as follows:

[0047]1. Put bamboo pulp and cotton pulp with an average degree of polymerization greater than 1000 on the pulp feeder, set a certain feeding speed (25kg / min), and then add alkali with a concentration of 85g / l and a temperature of 60°C to 90°C Liquid, lye flow rate is 10m 3 / h~20m 3 , and then through stirring, the pulp is broken and fully mixed with lye to prepare a solid and liquid mixture, which is called composite pulp porridge, and this process is called impregnation in technology.

[0048] Function: Make bamboo pulp and cotton pulp raw materials into a solid and liquid mixture, dissolve β-cellulose at the same time, increase the content of α-fiber, and produce alkali cellulose.

[0049] Control parameters: lye temperature: 75±15°C lye concentration: 85g / l

[0050] Compound pulp porridge concentration: 3.5±2% (mass percentage) Dipping time: 30±20min

[0051] Alternatively, the above cotton pulp and bamboo p...

Embodiment 2

[0063] The specific process steps are as follows:

[0064] 1. Put bamboo pulp and cotton pulp with an average degree of polymerization greater than 800 on the pulp feeder, set a certain feeding speed (25kg / min), and then add alkali with a concentration of 80g / l and a temperature of 60°C to 90°C Liquid, lye flow rate is 10m 3 / h~20m 3 , whose purpose is to accelerate the dissolution of lignin and impurities in bamboo pulp. Then, through stirring, the pulp is crushed and fully mixed with lye to prepare a mixture of solid and liquid, which is called composite pulp porridge, and this process is called impregnation in technology.

[0065] Function: Make bamboo pulp and cotton pulp raw materials into a solid and liquid mixture, which is called impregnation in technology, and dissolve β-cellulose at the same time, increase the content of α-fiber, and produce alkali cellulose.

[0066] Control parameters: lye temperature: 75±15°C lye concentration: 80g / l

[0067] Porridge...

Embodiment 3

[0080] The specific process steps are as follows:

[0081] 1. Put bamboo pulp and cotton pulp with an average degree of polymerization greater than 1200 on the pulp feeder, set a certain feeding speed (25kg / min), and then add alkali with a concentration of 100g / l and a temperature of 60°C to 90°C Liquid, lye flow rate is 10m 3 / h~20m 3 , Add auxiliary agent while adding lye: methyl isopropyl ketone (MIBK)-alcohol mixed solvent, wherein MIBK: ethanol=80: 50, its purpose is to accelerate the stripping of lignin and impurity in the bamboo pulp. Then, through stirring, the pulp is crushed and fully mixed with lye to prepare a mixture of solid and liquid, which is called composite pulp porridge, and this process is called impregnation in technology.

[0082] Function: Make bamboo pulp and cotton pulp raw materials into a solid and liquid mixture, which is called impregnation in technology, and dissolve β-cellulose at the same time, increase the content of α-fiber, and produce alk...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com