Mechanism natural sand gradation adjustment machine and production method of natural sand

A gradation adjustment machine and natural sand technology, which is applied in the field of machine-made sand manufacturing, can solve the problems of waste of raw materials, low production capacity, and poor results, and achieve the effects of avoiding pollution, high production capacity, and avoiding waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

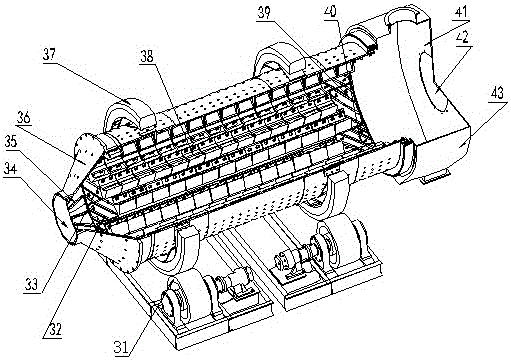

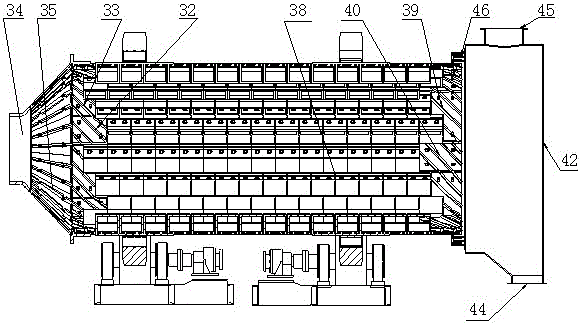

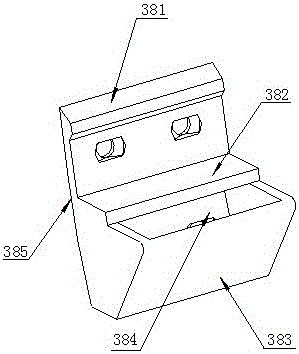

[0016] Embodiment 1: with reference to accompanying drawing 1 and 2 and Figure 5-7 . A machine-made natural sand gradation adjustment machine, the machine-made sand gradation adjustment machine 3 is composed of a power source 31, a second material guide liner 32, a first material guide liner 33, a wear-resistant ring 34 at the feed port, and a feed port end Lining plate 35, material inlet shell 36, large rolling ring 37, stepping counterattack hopper 38, first buffer lining plate 39, second buffer lining plate 40, dust removal cover 43, discharge port 44, dust removal hole 45 and labyrinth Groove 46 is formed; the two ends of the drum are respectively covered with large rolling rings 37, and the large rolling rings 37 are located on the power source 31. The feed inlet shell 36 constitutes the feed inlet, and a plurality of step-type impact hoppers 38 are arranged in three or more rows as a group and are distributed on the inner wall of the drum in a step-by-step structure. E...

Embodiment 2

[0021]Embodiment 2: On the basis of Embodiment 1, a method for making natural sand with a machine-made natural sand gradation adjustment machine, steel balls and machine-made sand to be adjusted enter the machine-made sand gradation adjustment machine 3 together, and the machine-made sand gradation adjustment machine The rolling of 3 drives the stepping hopper 38 to continuously lift and discharge the material. The steel ball and the machine-made sand that needs to be adjusted are lifted to the top and fall at the same time. When it falls to the counterattack surface, it can hit the machine-made sand that needs to be adjusted on the counterattack surface, and can hit the machine-made sand on the adjacent counterattack surface after rebounding. The mixture of machine-made sand and steel balls accumulated in the lower part is continuously beaten, rolled and ground, and then lifted to the top by the next level of bucket elevator, and the process of falling, being beaten, grinding ...

Embodiment 3

[0022] Embodiment 3: with reference to attached image 3 and 4 . A machine-made natural sand sand making system composed of a machine-made natural sand gradation adjustment mechanism. The feeding conveyor belt 1 discharge end is directly facing the steel-sand mixing hopper 2 feeding port, and the steel-sand mixing hopper 2 passes through the steel ball feeding chute 16 is opposite to the outlet of the tower type steel ball bucket elevator 15, the bottom of the tower type steel ball bucket elevator 15 is located in the crude steel trough 14, the outlet of the steel sand mixing hopper 2 is connected to the machine-made sand grading adjustment machine 3 The feed port is connected, the machine-made sand grading adjustment machine 3 dust collection cover 5 is connected with the dust collector 4 through the conveying pipe, the machine-made sand grading adjustment machine 3 discharge port is opposite to the feed end of the discharge conveying conveyor belt 17, and the discharge conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com