Method of processing synthetic resin tubular body

A technology of synthetic resin and processing method, applied in the direction of flexible tubular container, container, rigid container, etc., can solve the problem of only limited container identification function and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

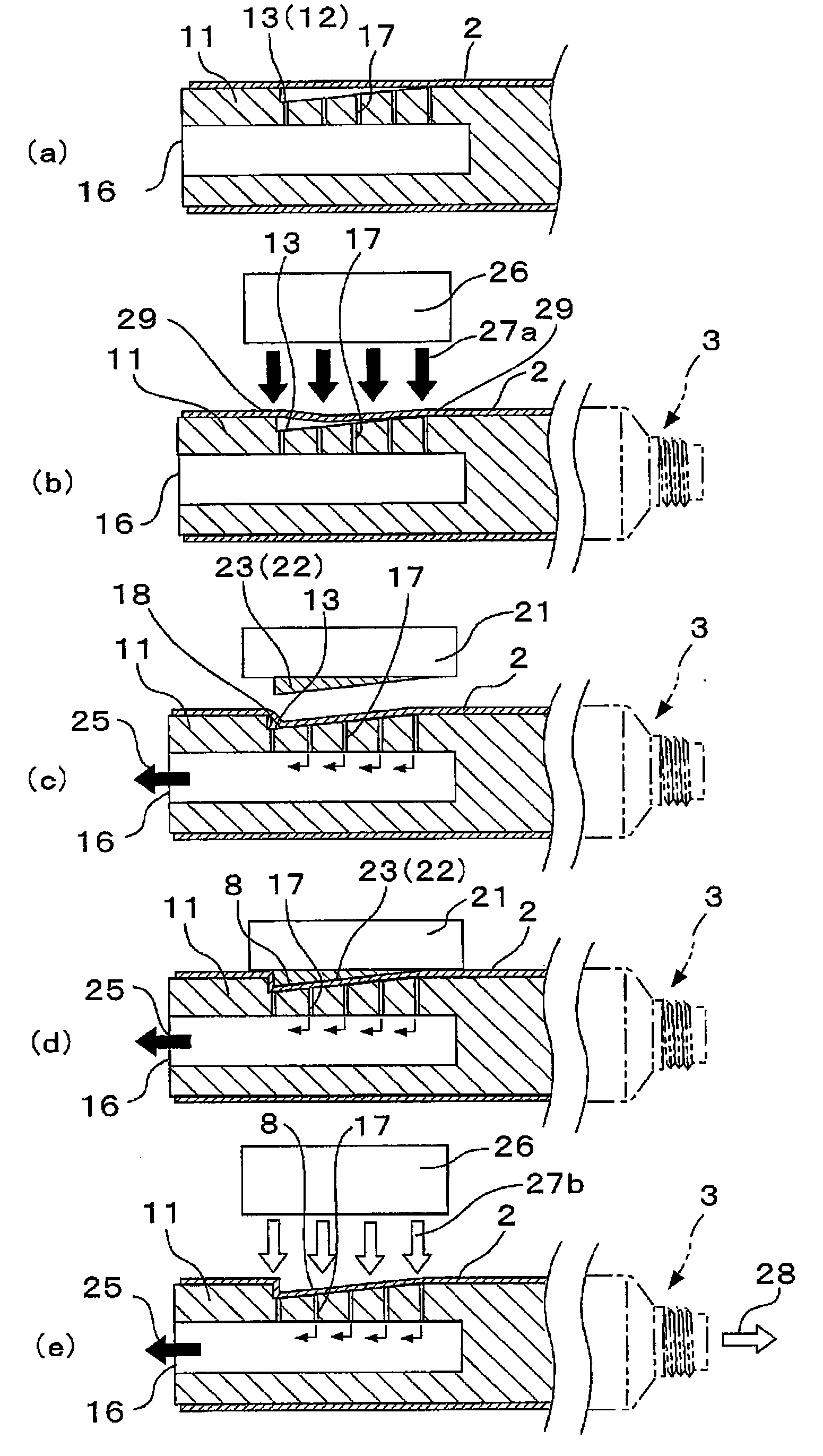

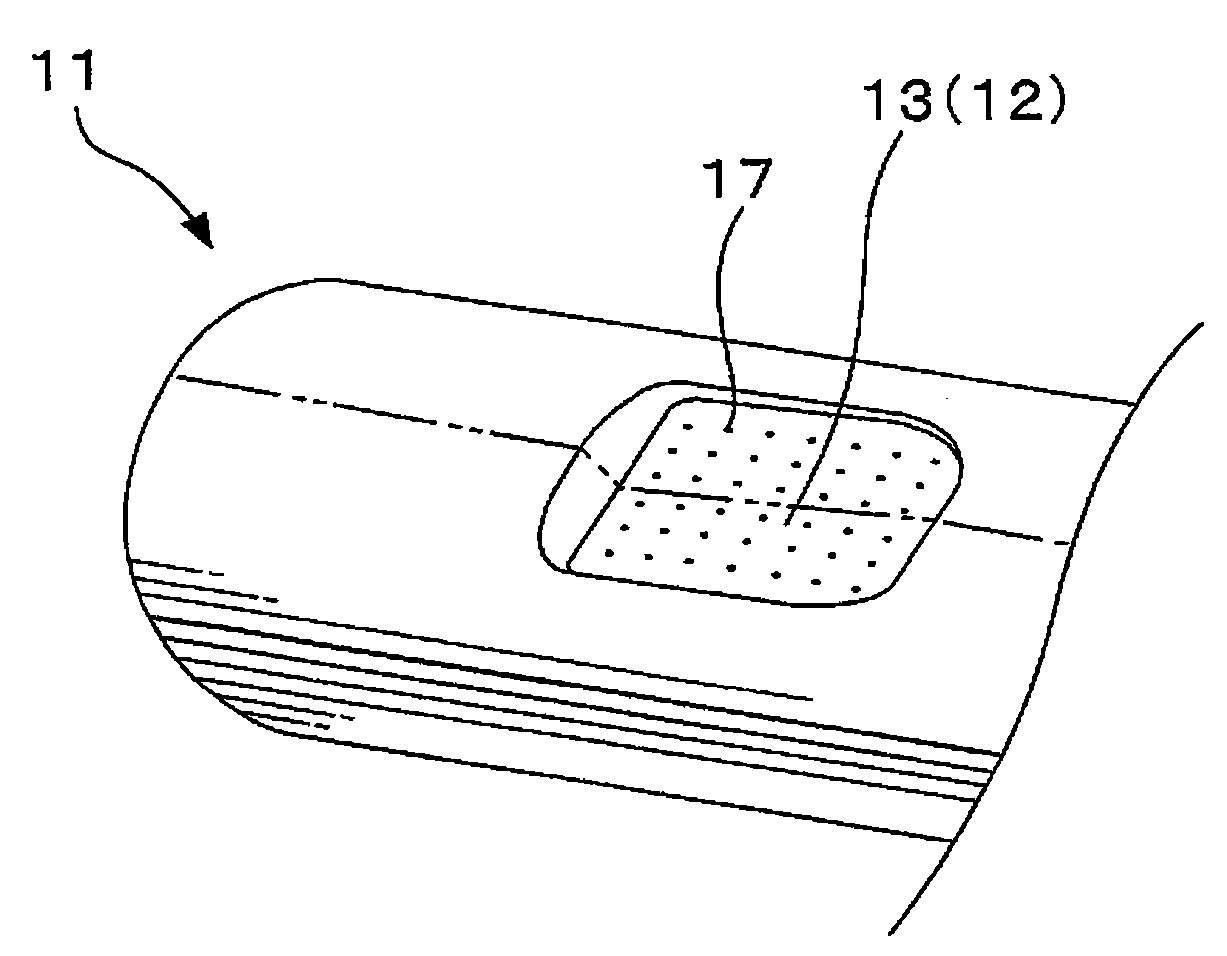

[0068] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings.

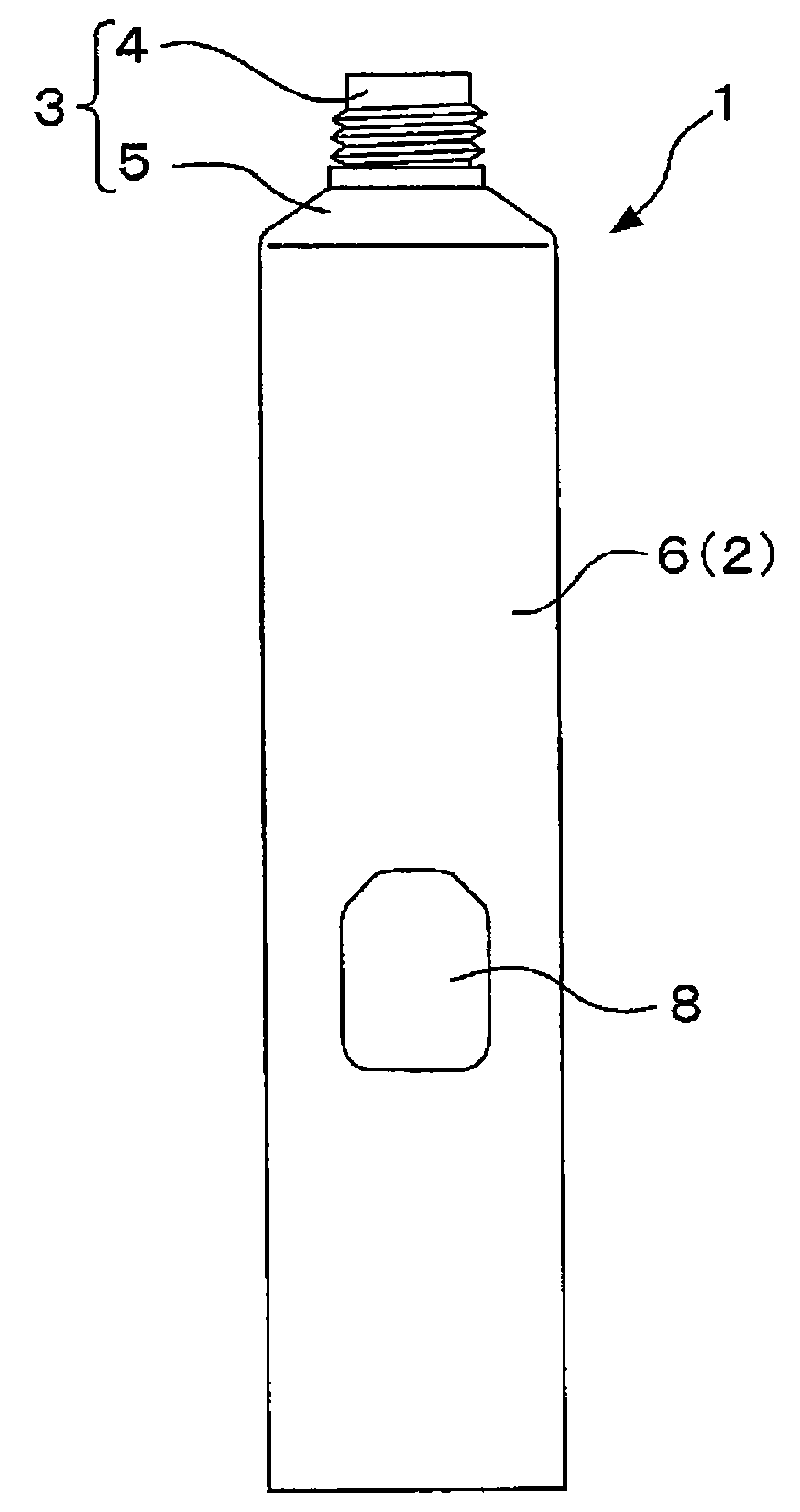

[0069] Figure 3 to Figure 5 This is an example of the tubular container of the present invention produced by the first embodiment of the synthetic resin tubular body processing method of the present invention. image 3 and Figure 4 is the front view and side view showing the bottom unsealed state, Figure 5 It is a side view which shows the state in which the bottom seal part 7 was formed in the bottom part, and the inner diameter of this container is 25 mm, and the length is 150 mm.

[0070] like image 3 As shown, the tubular container 1 consists of a tubular body 2 and a head 3, wherein the tubular body 2 is cylindrical and is used to form a body 6; the head 3 consists of a shoulder 5 and a mouth 4, which are formed by injection molding Or compression molding, the head 3 is mounted on one end of the tubular body 2 and integrated, and after filling ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com