Novel windscreen wiper

A wiper, a new type of technology, applied in the direction of vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve the problems of wiper strip wear, glass scratches, scratches, etc., to improve service life, reduce friction, reduce The effect of dry grinding conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

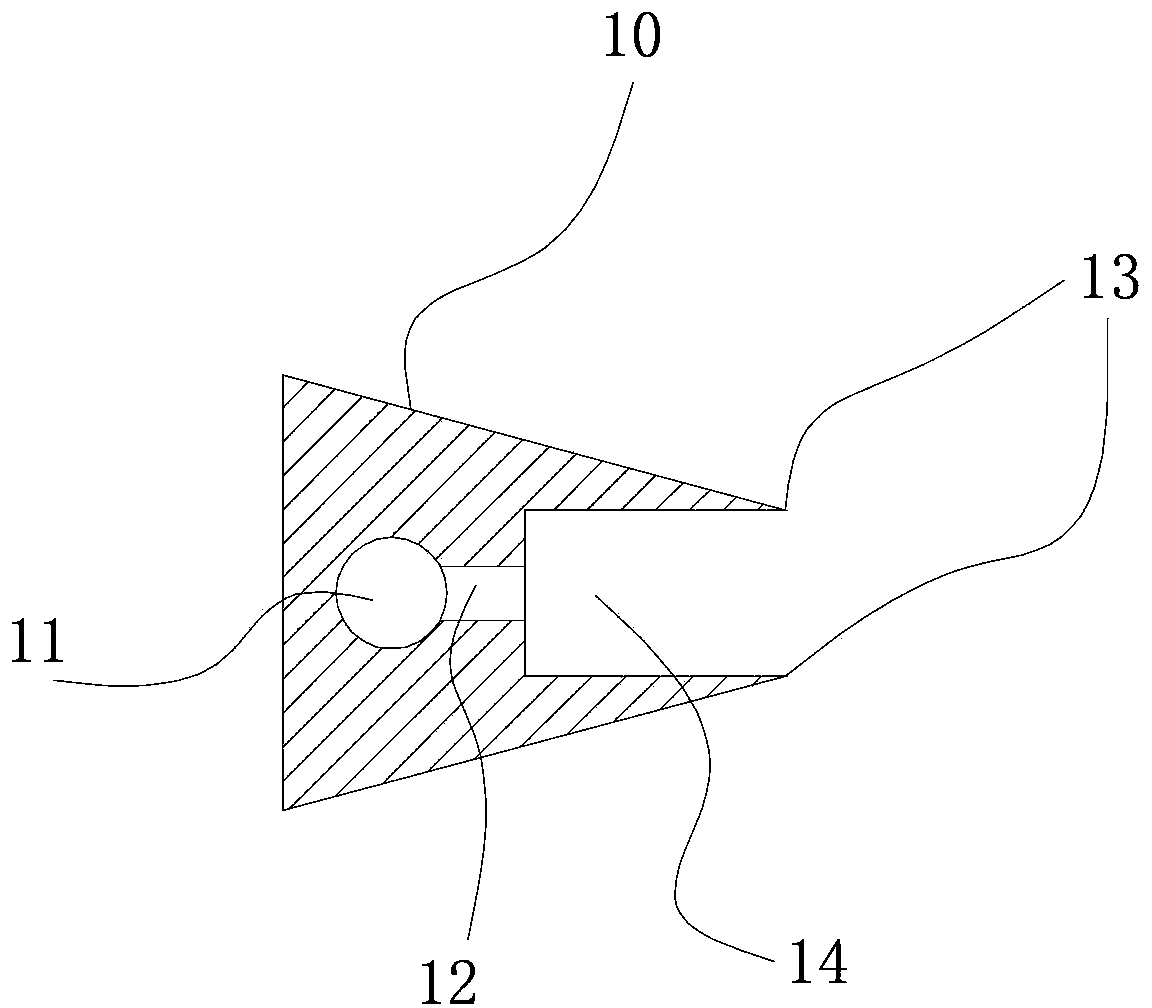

[0035] Such as Figure 1 to Figure 2 In the specific embodiment shown, a new wiper blade of the present invention includes a wiper strip 10 , and the wiper strip 10 is provided with a liquid cavity 11 and several liquid outlets 12 connected with the liquid cavity 11 . The contact edge between the wiper strip 10 and the surface to be scraped (such as the front window glass of an automobile) is two sharp edges 13; a liquid storage tank 14 is arranged between the two sharp edges 13; the bottom of the liquid storage tank 14 is provided with The several liquid outlets 12 described.

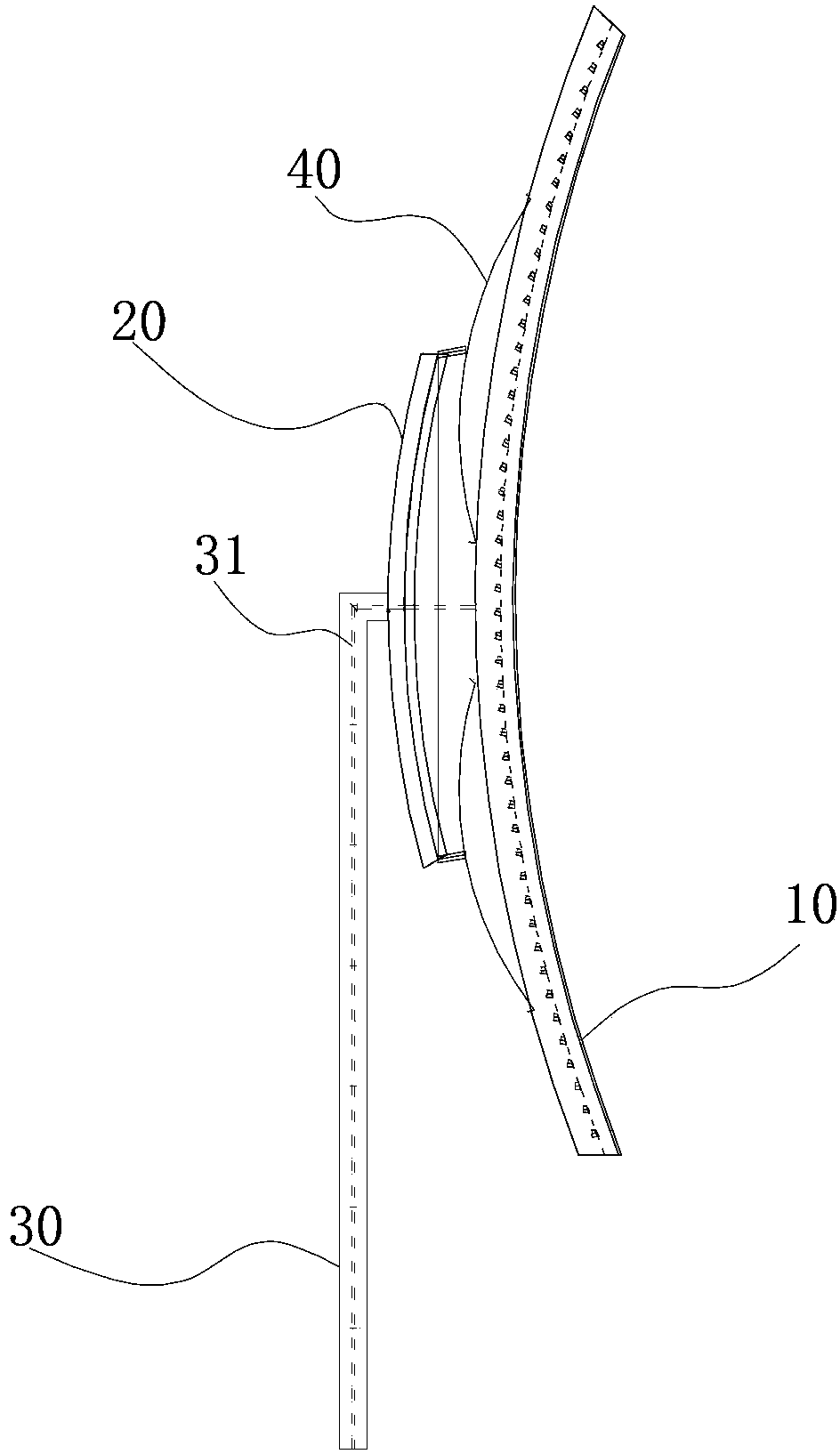

[0036] It also includes a fixed bracket 20 for fixing the wiper strip 10 , and a rotating bracket 30 detachably connected with the fixing bracket 20 ; the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com