Load-shedding type sound barrier structure for high speed railway

A technology for high-speed railways and sound barriers, applied in noise absorption devices, buildings, etc., can solve problems such as huge train aerodynamic loads, and achieve the effects of easy installation, easy processing, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

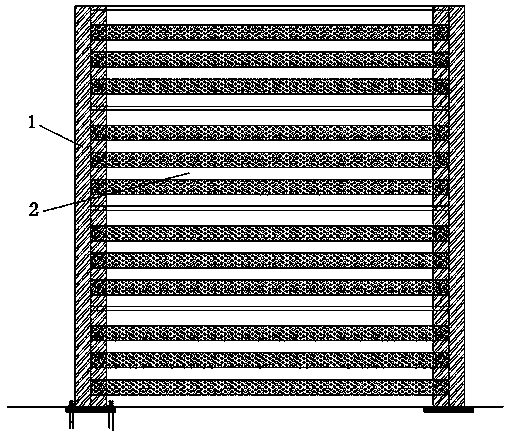

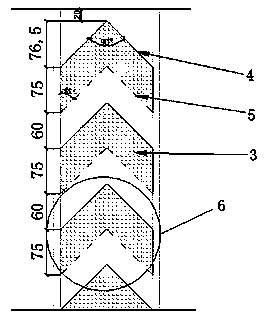

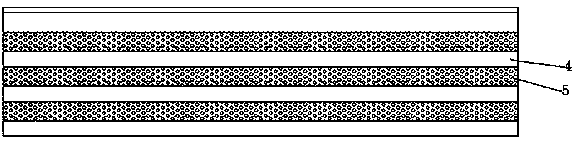

[0026] The invention changes the form of the sound barrier made of solid materials in the past, and designs the sound barrier as a sound-absorbing unit with air-permeable performance combined with a sheet structure having both sound-absorbing and sound-insulating properties. figure 1 It is the elevation view of the load-reducing sound barrier structure of the high-speed railway of the present invention. Such as figure 1 As shown, the load-reducing sound barrier structure of the high-speed railway of the present invention includes H-shaped steel columns 1 arranged at both ends and a plurality of sound barrier unit panels 2 arranged between the two H-shaped steel columns 1 . The cross-section of the H-shaped steel column 1 is H-shaped with 175mm*175mm. Multiple sound barrier unit panels 2 can be inserted between two H-shaped steel columns 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com