Brake hub for novel automobile

A technology for brake hubs and automobiles, applied in the direction of brake drums, etc., can solve the problems of insufficient strength, low service life, easy fracture of stressed parts, etc., and achieve the effect of increasing the friction area of the brake, improving the heat dissipation performance and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

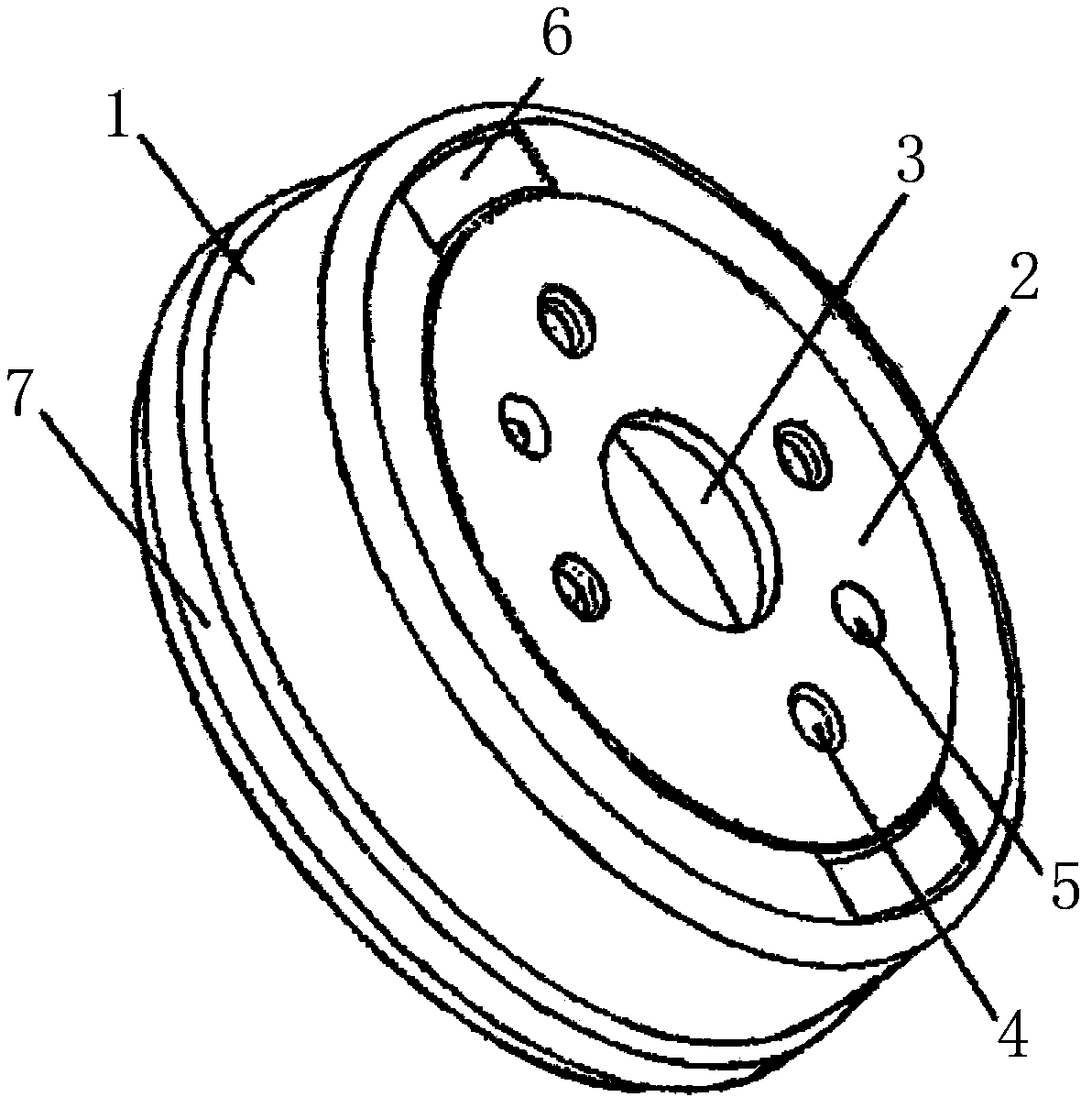

[0009] like figure 1 As shown, the present invention is provided with a connecting disk 2 on the inner wall of one end of the annular cylindrical hub body 1, and is provided with a shaft hole 3 at the middle part of the connecting disk 2, and is evenly arranged with four installations on the outer circumference of the shaft hole 3. Hole 4 and two dismounting holes 5, two observation holes 6 are correspondingly arranged on the edge of connecting disc 2, and reinforcing hoop 7 is sleeved on the outer diameter of the other end of annular cylindrical hub body 1. Through the above settings, the shaft hole 3 on the connecting disk 2 of the present invention passes through the shaft head of the rear axle of the automobile and is installed on the two ends of the rear axle of the automobile, and forms the shaft hole cooperation with the wheel hub, and is fastened through the mounting hole 4 with four bolts. Together. The observation hole 6 connecting the edge of the disc 2 is convenie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com