Green waterproof non-gel type bath-sanitation wall body plate and manufacturing method thereof

A type of glue type and board technology, applied in chemical instruments and methods, building materials, building components, etc., can solve the problems of reducing the service life of boards, limited overall product quality improvement, single color, etc., to improve structural bearing capacity and appearance. Variety, overall high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

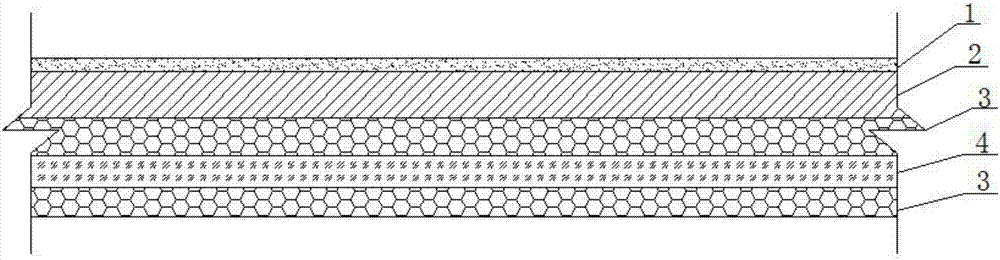

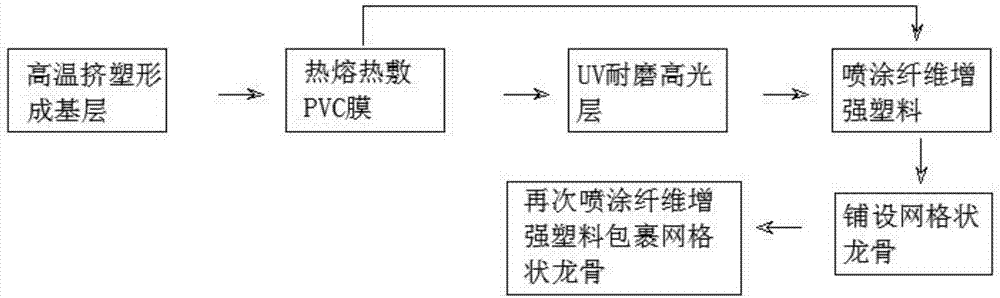

[0027] Put polyvinyl chloride resin and calcium carbonate powder in extrusion equipment at a mass ratio of 1:1, extrude at a temperature of 180°C to form a 5mm thick PVC stone-plastic board base 2, and cool to 80°C after extrusion ℃, the surface layer and the PVC film are integrated to form a surface layer 1 with a thickness of 0.1 mm; the other side of the PVC stone-plastic board that has not been heat-applied with the PVC film is sprayed with 2 mm thick 191 benzene-type unsaturated polyester resin and aromatic A mixture of aramid fiber (the content of aramid fiber in the mixture is 5wt%, and 191 benzene-type unsaturated polyester resin completely infiltrates the aramid fiber). The height is 20mm, the thickness is 1.5mm, and the spacing is 250mm. It is composed of grid-shaped galvanized square tubes, and then sprayed with a mixture of 191 benzene-type unsaturated polyester resin and aramid fiber with a thickness of 1.5mm to wrap the grid-shaped keel completely. After curing f...

Embodiment 2

[0029] Put polyvinyl chloride resin and calcium carbonate powder in extrusion equipment at a mass ratio of 1:1, extrude a 3.5mm thick PVC stone-plastic board base layer 2 at a temperature of 220°C, and cool to 150°C after extrusion , the front of the base layer is vacuum-coated with a layer of PVC film, and coated with UV varnish, heated to 50°C and kept leveling for 3 minutes, irradiated with a 2KW UV curing machine for 10s, and then undergoes rapid ultraviolet light curing treatment to obtain a wear-resistant high-gloss layer. The PVC film and the wear-resistant high-gloss layer jointly form the surface layer 1; spray a mixture of 1mm thick 2608 xylene type unsaturated polyester resin and carbon fiber on the back of the PVC stone-plastic plate (the carbon fiber content in the mixture is 10wt%, and the 2608 xylene type is not Saturated polyester resin completely infiltrates the carbon fiber), and after solidification, the grid-shaped keel is laid as the structure 4. The grid-s...

Embodiment 3

[0031] Put polyvinyl chloride resin and calcium carbonate powder in extrusion equipment at a mass ratio of 1:2, extrude a 3.5mm thick PVC stone-plastic board base layer 2 at a temperature of 180°C, and cool to 150°C after extrusion , the front of the base layer is vacuum-coated with a layer of PVC film, and coated with UV varnish, heated to 50°C and kept leveling for 3 minutes, irradiating the surface with a 2KW UV curing machine for 10 seconds, and performing rapid ultraviolet light curing treatment to obtain a wear-resistant high-gloss layer. The PVC film and the wear-resistant high-gloss layer jointly form the surface layer 1; one side of the PVC stone-plastic plate that is not hot-coated with the PVC film is sprayed with 2mm thick 191 benzene-type unsaturated polyester resin and glass fiber mixture (glass fiber content in the mixture is 15wt%) ), after solidification, the grid-shaped keel is laid as the structure 4. The keel is composed of grid-shaped galvanized square tube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com