High-internal-strength filter felt

A filter felt, high-strength technology, applied in the field of filter felt, can solve problems such as insufficient strength, machine downtime, economic loss, etc., achieve the effect of strength optimization and avoid bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

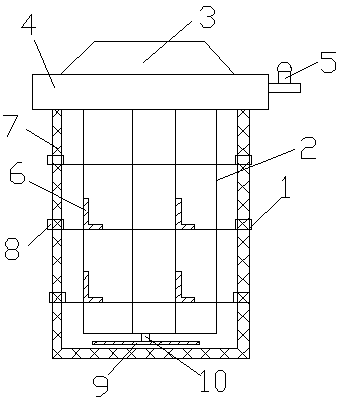

[0012] An internal high-strength filter felt is provided with a cover 1 and a support frame 2, the support frame 2 is externally sleeved with a cover 1, and the cover 1 is provided with air holes, and the cover 1 is provided with an air inlet 3 , the air inlet 3 is provided with a fixed end 4, the fixed end 4 is a steel hoop, and a tightening knob 5 is provided on the fixed end 4, and the tightening knob 5 is passed by an external force Tighten so as to lock the steel hoop, and the support frame 2 is provided with cross or L-shaped reinforcing ribs 6 .

[0013] The reinforcing rib 6 is welded and fixed on the inner wall of the support frame 2 .

[0014] The outer cover 1 is a non-woven fabric outer cover, and a stainless steel wire mesh 7 is arranged inside the outer cover 1 .

[0015] The stainless steel wire mesh 7 and the outer cover 1 are connected to each other, and the stainless steel wire mesh 7 is fixed on the inner side of the outer cover by twisted wires 8 .

Embodiment 2

[0017] An internal high-strength filter felt is provided with a cover 1 and a support frame 2, the support frame 2 is externally sleeved with a cover 1, and the cover 1 is provided with air holes, and the cover 1 is provided with an air inlet 3 , the air inlet 3 is provided with a fixed end 4, the fixed end 4 is a steel hoop, and a tightening knob 5 is provided on the fixed end 4, and the tightening knob 5 is passed by an external force Tighten so as to lock the steel hoop, and the support frame 2 is provided with cross or L-shaped reinforcing ribs 6 .

[0018] The reinforcing rib 6 is welded and fixed on the inner wall of the support frame 2 .

[0019] The outer cover 1 is a non-woven fabric outer cover, and a stainless steel wire mesh 7 is arranged inside the outer cover 1 .

[0020] The stainless steel wire mesh 7 and the outer cover 1 are connected to each other, and the stainless steel wire mesh 7 is fixed on the inner side of the outer cover by twisted wires 8 .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com