A kind of shoe upper and its manufacturing method

A production method and a technology for shoe uppers, which are applied to shoe uppers, footwear, boot legs, etc., can solve the problems of many processes and low efficiency, and achieve the effects of simple processing technology, improved production efficiency, and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to facilitate the understanding of those skilled in the art, the principle of the present invention will be further described in detail below in conjunction with specific embodiments.

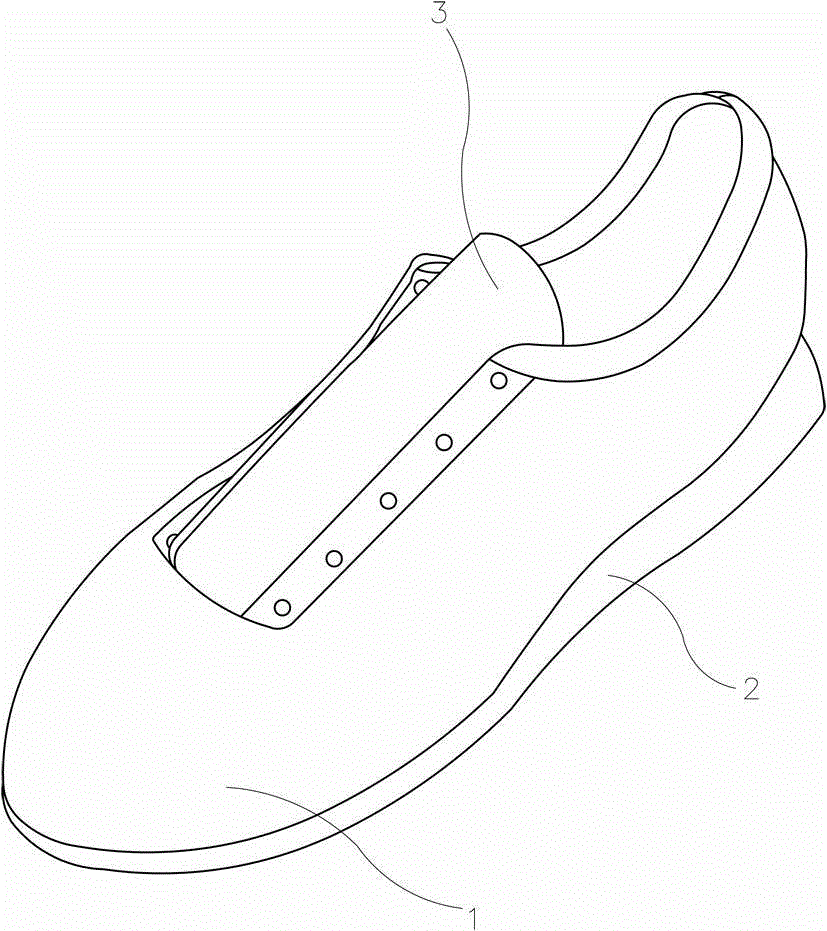

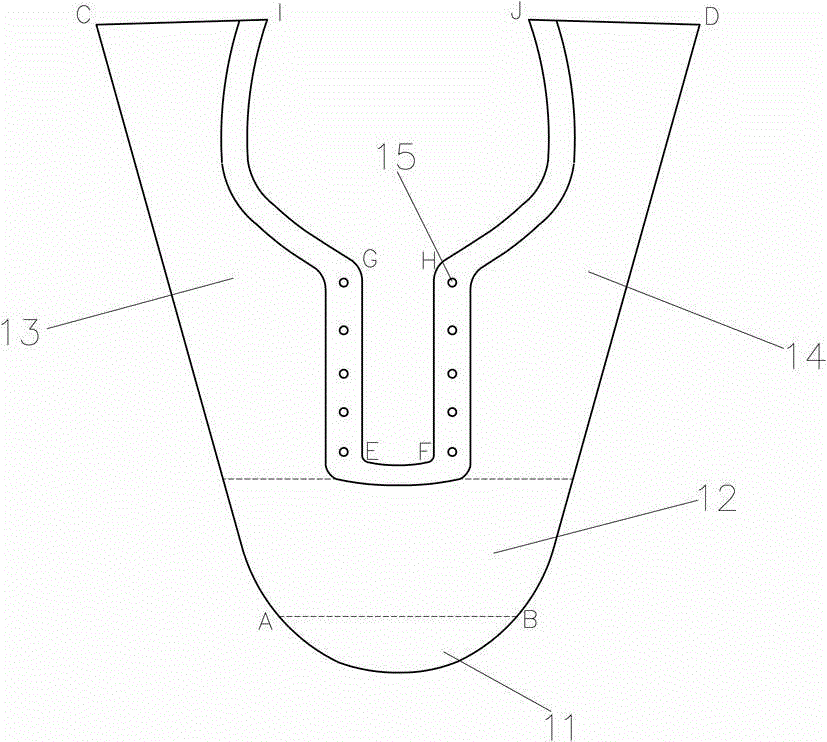

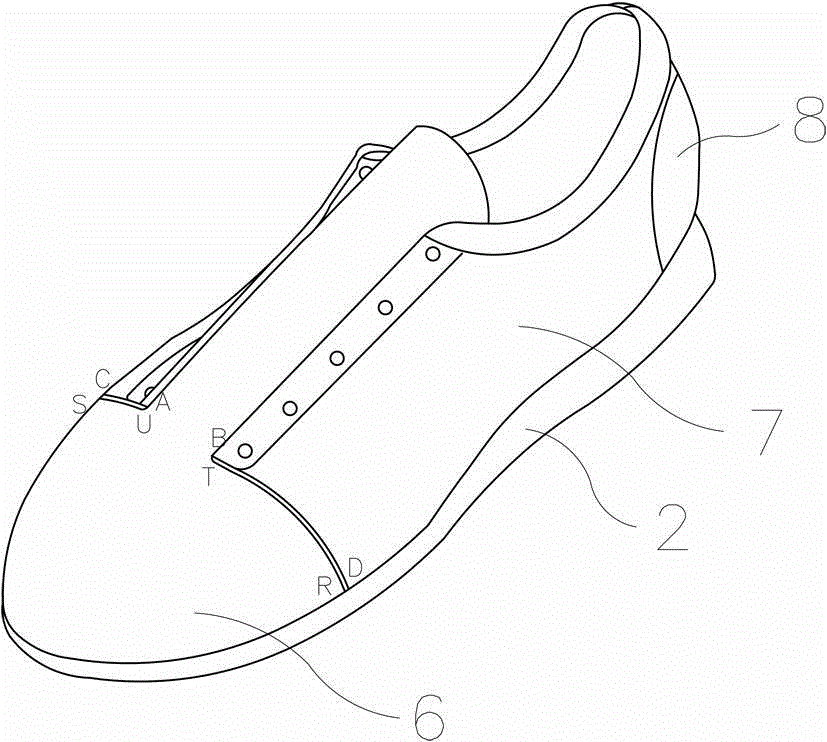

[0025] Such as Figure 3~5 As shown, the present invention discloses a first vamp, including a front end structure 6 constituting the toe part and a rear end structure 7 constituting the middle section of the shoe body and the heel, the front end structure 6 and the rear end structure 7 are respectively woven by a flat knitting machine Forming, the front end structure 6 and the rear end structure 7 respectively leave two suture sections SU and RT sections connected together, the rear end structure 7 forms an ankle support opening for feet to enter and exit, and the front end structure includes a toe cap The knitting part 32 and the tongue knitting part 21, the toe knitting part 32 and the shoe tongue knitting part 21 are formed by knitting on a flat knitting machine, and the toe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com