Metal strip pure extension straightening used convexity variable tension roller system

A metal strip and tension roller technology, applied in the field of variable crown tension roller system, can solve the problem of inability to correct the shape of the plate, and achieve the effect of reducing scratches and dependencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

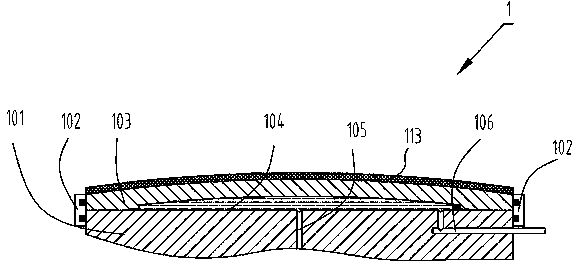

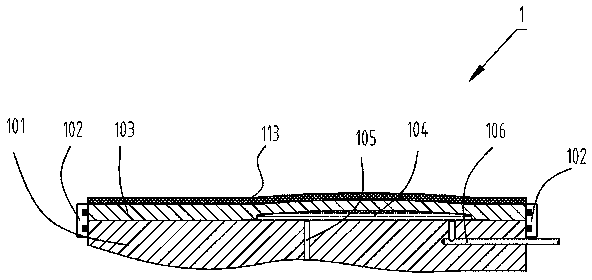

[0023] The variable crown tension roller is used, and by controlling the fluid pressure in the sealing oil chamber between the mandrel and the bushing, the roller surface in contact with the strip can have a certain degree of convexity, thereby improving the metal strip. The purpose of shape defects.

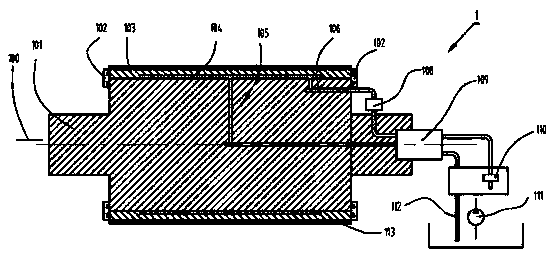

[0024] like figure 1 As shown, the variable crown tension roll system 1 for pure stretching and straightening of metal strips includes a mandrel 101, a roll sleeve 103, at least one sealed cavity 104 formed between the roll sleeve 103 and the mandrel 101, and a hydraulic system The oil inlet pipeline 106 connected with the sealed cavity 104 is connected with the rotary joint 109 through the pressure transmission device 108, the oil return pipeline 105 connected with the sealed cavity 104 is connected with the rotary joint 109, and the rotary joint 109 is connected through the pipeline into the hydraulic system; the hydraulic system includes a hydraulic station 111 and a pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com