Liquid wax insulation device

A heat preservation device and wax liquid technology, which is applied in the direction of casting and molding equipment, etc., can solve the problems of cooling the wax liquid, affecting the normal production of wax slurry, troubles, etc., and achieve the effect of preventing partial solidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The wax liquid heat preservation device of the present invention will be further described in detail below with reference to the drawings and specific embodiments:

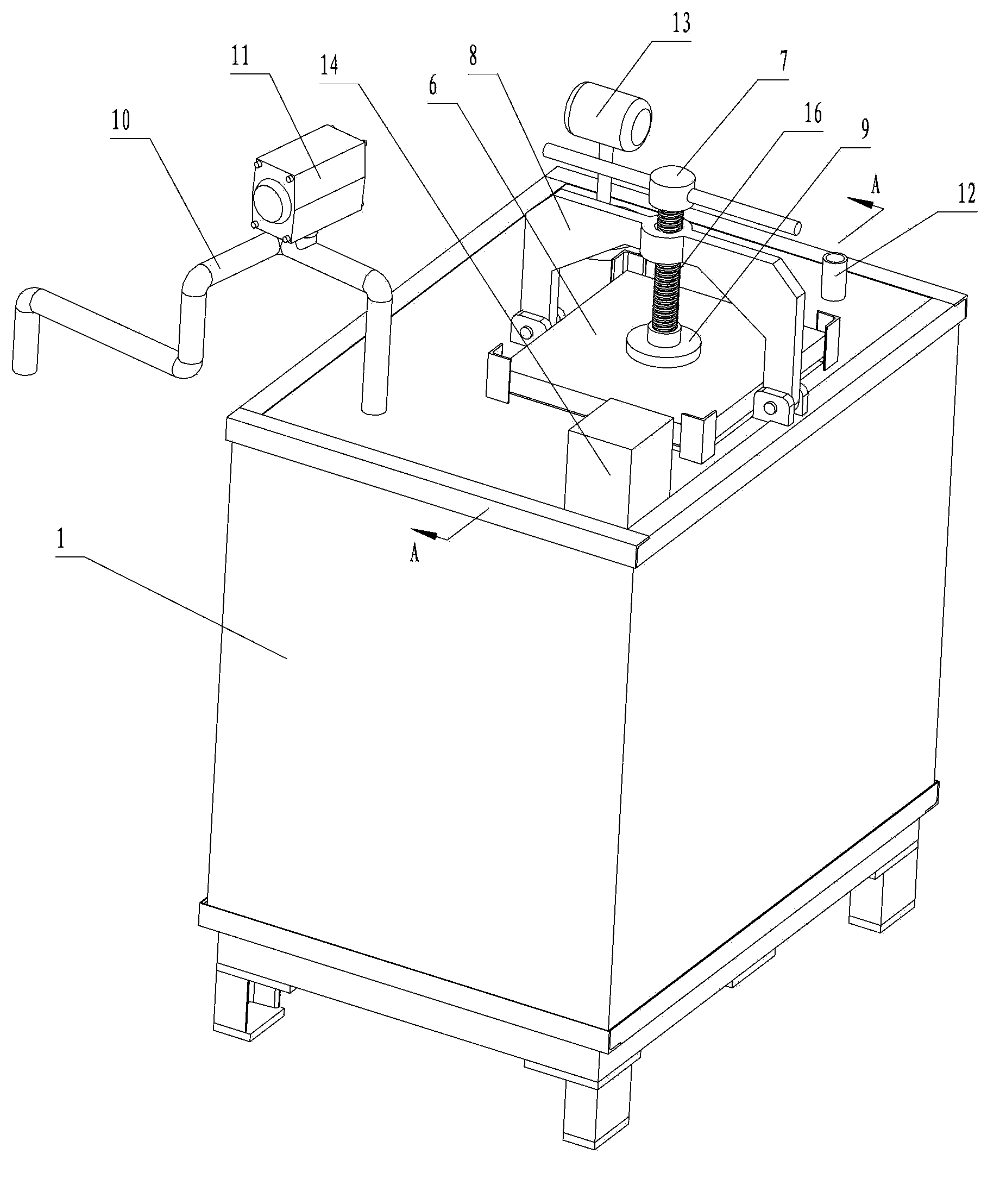

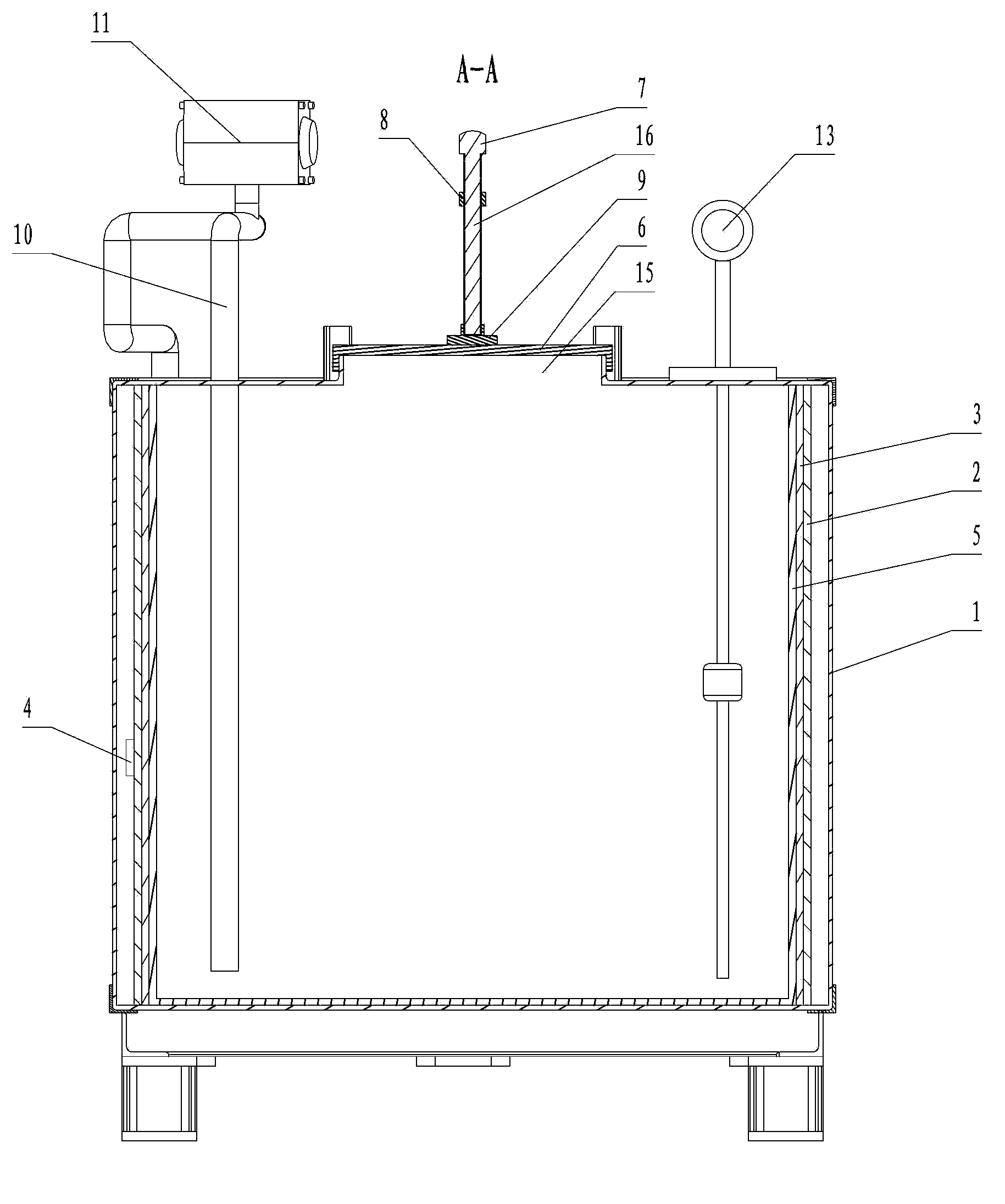

[0009] Such as figure 1 with figure 2 As shown, in this specific embodiment, the wax liquid insulation device of the present invention includes a housing 1, a temperature sensor 4, a wax storage bucket 5, a cover 6, a rotary handle 7, a rotary handle seat 8, a pressure block 9, and a pneumatic ball valve switch 11. Air source interface 12, liquid level switch 13, central controller 14, heating layer 3 made of silicone rubber heating belt, insulation layer 2 made of high-temperature insulation cotton, and wax liquid delivery made of insulated pipes Tube 10, the wax storage bucket 5 is located in the shell 1, the heating layer 3 is wrapped on the outer peripheral wall of the wax storage bucket 5, the insulation layer 2 is wrapped outside the heating layer 3, the temperature sensor 4 is installed on the insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com