Horizontal type gear hobbing machine workpiece rotation main shaft box adjustment technology

A technology of gear hobbing machine and spindle box, which is applied in the field of adjustment process of horizontal gear hobbing machine workpiece rotary spindle box, can solve the problems of adjustment accuracy and time cannot be guaranteed, and achieve the effect of easy micro-adjustment, convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

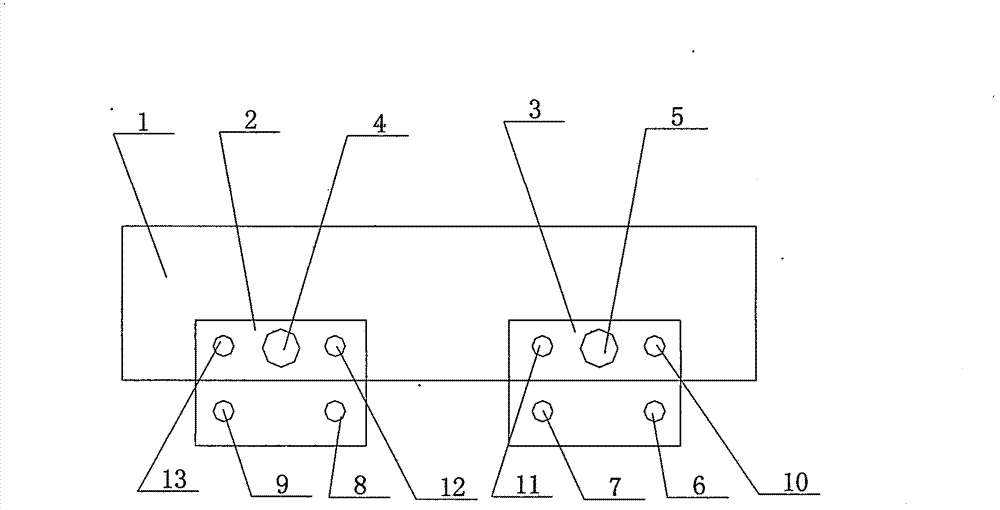

[0008] see figure 1 , the specific embodiment is to adopt the following technical scheme: it comprises the spindle box 1, the first adjustment platen 2, the second adjustment platen 3, the first tension hole 4, the second tension hole 5, the first screw hole 6, The second screw hole 7, the third screw hole 8, the fourth screw hole 9, the fifth screw hole 10, the sixth screw hole 11, the seventh screw hole 12 and the eighth screw hole 13; main shaft One side of the box 1 is provided with a first adjusting platen 2 and a second adjusting platen 3, and the first adjusting platen 2 and the second adjusting platen 3 are respectively provided with a first tensioning hole 4, a third support screw hole 8, and a fourth support screw hole. Screw hole 9, screw hole 12 for the seventh screw, screw hole 13 for the eighth screw, second tension hole 5, screw hole 6 for the first screw, screw hole 7 for the second screw, screw hole 10 for the fifth screw, sixth screw hole Hole 11.

[0009] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com