Laser marking device for circular sawing machine

A technology of laser marking and circular sawing machine, which is applied in the direction of sawing machine accessories, sawing machine devices, metal sawing equipment, etc., and can solve the problems of users' dimensional cognition confusion, limited adjustment, slow adjustment speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

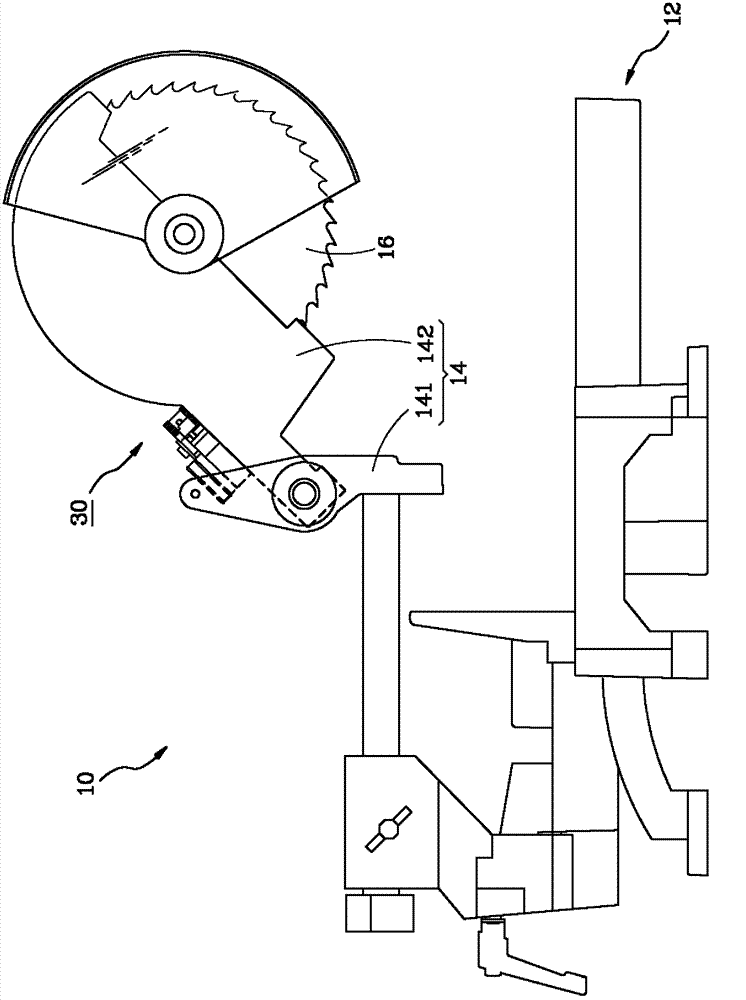

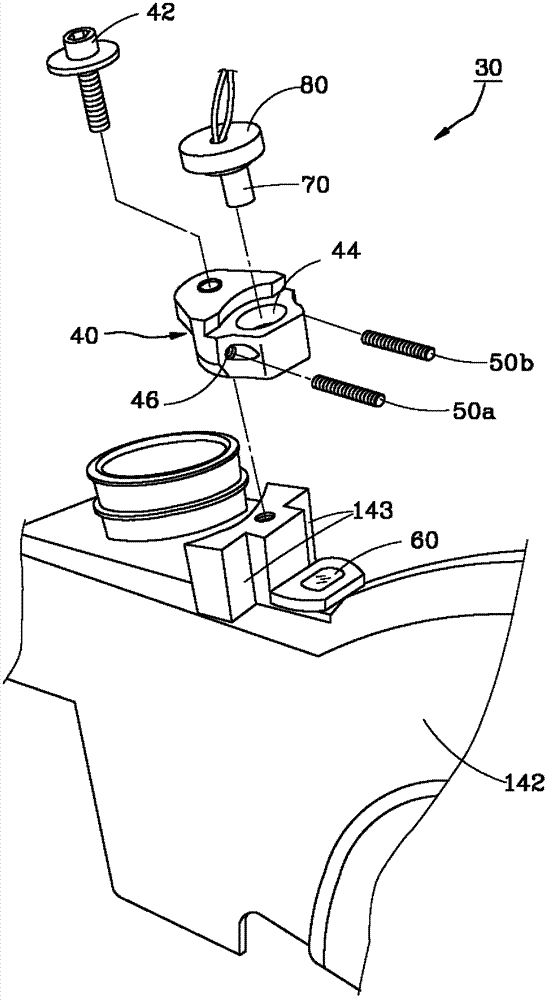

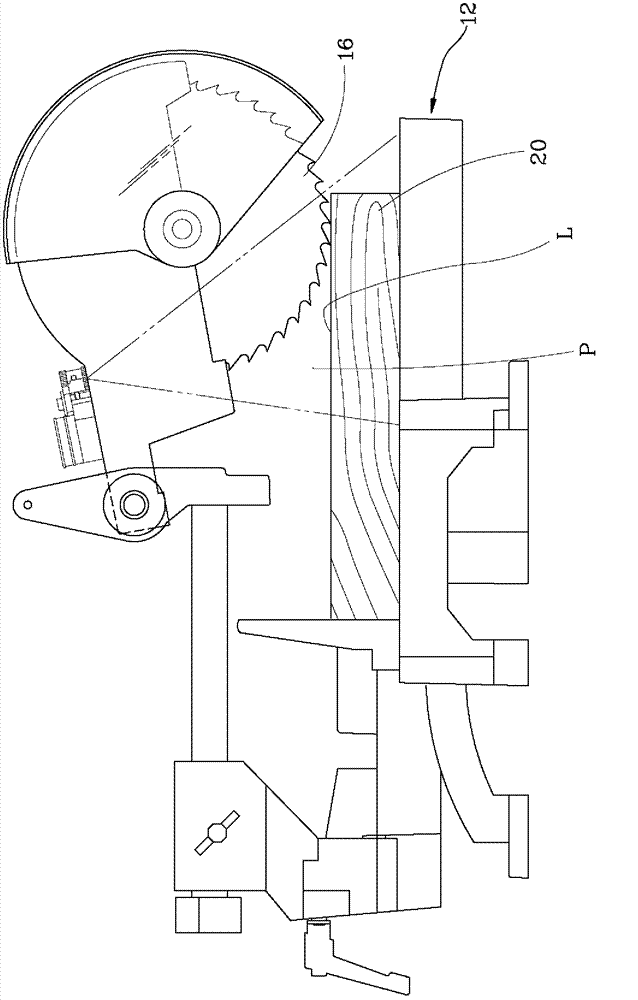

[0029] The laser marking device of the present invention includes an adjustment seat, a lens, and a laser generator. The adjustment seat is pivoted on a saw arm of the circular saw machine by a rotating shaft and has a through hole; the lens is arranged on the saw arm corresponding to the adjustment seat; the laser generator is arranged on the knob and accommodated in the adjustment seat In the through hole, it is used to generate a laser beam. As a result, when the laser beam passes through the lens, it will diffuse to form a plane beam, which is projected on a workpiece to form a laser marking line. The plane beam can be moved in a swing by the pivoting of the adjustment seat relative to the saw arm, The plane light beam is quickly switched between a predetermined first plane position and a predetermined second plane position substantially parallel to the planes on both sides of the saw blade, so that the purpose of quickly adjusting the laser marking line can be achieved. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap